Loading Port:Lianyungang

Payment Terms:TT OR LC

Min Order Qty:0 m

Supply Capability:500 m/month

FRP chimney:

Chimney is the main way of coal emission in thermal power, metallurgy and other industries. Take the thermal power industry as an example. In the past, the industry used to dust only the exhaust from coal burning, which was emitted into the surrounding atmosphere through tall chimneys. Nowadays, due to the requirements of environmental protection to strictly control the emission of sulfur dioxide, it is necessary to desulphurize the waste gas. At present, most thermal power industry adopts wet desulphurization. Before the wet desulphurization process, although the flue gas contains more sulfur dioxide, but the temperature of flue gas entering the chimney is high, up to 130-160℃, only a small amount of flue gas condensation phenomenon, the anti-corrosion requirements of tobacco meat is not very high. However, after wet desulfurization, the flue gas temperature drops to 50-80℃, and the moisture content of flue gas is higher, which leads to the increase of the probability of the inner wall corrosion of the chimney. Although the flue gas temperature drops to 50-80℃ after wet desulphurization, the flue gas temperature (about 150℃) in emergency state without wet desulphurization and the temperature in accident state (nearly 200℃) should be considered in the design of the chimney, so the wet desulphurization chimney has high requirements on corrosion resistance and temperature resistance. In order to solve the serious corrosion of the inner wall of chimney caused by the installation of wet desulphurization device, technicians at home and abroad have carried out a lot of research and engineering test work. At present, the commonly used anti-corrosion materials of chimney include acid-resistant brick - acid-resistant mortar, steel-titanium composite structure, steel-stainless steel composite structure, steel-coating material and hard E-276 alloy lining, etc. Compared with other materials, the new FRP chimney has the advantages of corrosion resistance, low investment, short construction period, light weight and long life.

FRP chimney application:

After reasonable design, manufacture and installation, glass fiber reinforced plastics (FRP) is used in the structure and whole equipment of wet desulphurization system. It has obvious technical, economic and social benefits, long service life, reliable operation, and has been widely used at home and abroad. The technical and economic analysis is feasible. Compared with the traditional chimney made of alloy steel, carbon steel lined with rubber and carbon steel coated with resin scales, the fiberglass chimney has the advantages of strong corrosion resistance, long service life, high strength and energy saving, which provides a way to reduce the cost of desulfurization equipment made in China.

Comparison of advantages and disadvantages between FRP chimney and other materials

I. Fiberglass chimney:

1. Excellent corrosion resistance, the flue gas contains quite a lot of HCL, H2SO4, and other strong chemical substances corrosion resistance is very good

2. Overall structure, no corrosion weak point

3. Long life and low cost

4. No maintenance for a long time, excellent high temperature resistance

5. The product has strong designability and can be customized according to different needs of customers.

II.Titanium (Brocade) alloy composite steel plate lining has excellent anticorrosion performance, and the weld area is prone to corrosion, which is expensive

III.Steel inner cylinder:

1. Foam glass brick: strong corrosion resistance; The construction technology is complex and the time limit is long

2. Spraying anti-corrosion concrete: the construction conditions are poor and the construction process is complex

3. Spraying high performance heat and acid resistant coating: short service life, complex maintenance

4. Masonry glazed acid-proof brick smoke exhaust pipe: the manufacturing period is long.

Structural form of FRP chimney:

Fiberglass reinforced concrete chimney:

It is mainly used for the inner tube of concrete bacon with the height of flue gas from 100m to 240m. In this structure, the characteristics of high temperature and corrosion resistance of FRP are fully used, and concrete chimney provides support. Some projects are a concrete chimney with 1 FRP inner tube, and some with 2 or 3 FRP inner tube, depending on the design and requirements of the owner. The concrete inner tube of glass fiber reinforced plastic generally adopts the structure of section hanging wall. Steel structure embedded in concrete chimney as support system. Generally 3050 meters for a section, each section is connected with expansion joints, every 15 meters to design a guide support.

Installation steps of FRP chimney:

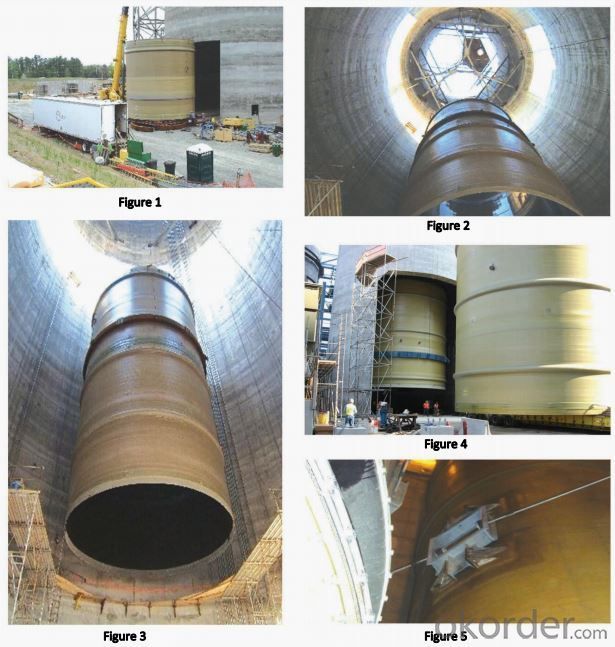

Step 1: Transport the first section of the inner tube of the pancetta to the bottom of the pancetta with a flatbed cart. (see figure 1)

Step 2: Connect the first section of bacon bobbin with the lifting sling; Lift the bottom of the pipe section to the height of the connecting platform. (see figure 1)

Step 3: Use a flatbed car to send the second section of pancetta inner tube, and adjust the position, so that it is aligned with the first section.

Step 4: Complete the butt production of the second paragraph and the first paragraph. Remove the sling on the first section and lift the first and second sections with the lifting ring on the second section.

Step 5: Lift the connected first and second sections to the position of the connecting platform. (see figure 3)

Step 6: Connect the new pipe section to the above pipe section. Repeat steps 3 to 5. (see figure 4)

Step 7: Adjust the upper and lower positions of the inner cylinder through the hydraulic lifting device to coordinate and fix the supporting pipe section with the supporting steel platform.

Step 8: Fix the stop point at 1/2. (see figure 5)

FRP chimney performance cases:

Datang Hushan Power Plant DN7200mm*24000mm

Shilian Chemical (Huai 'an) Co., LTD DN3000mm*120000mm

Inner Mongolia Huadian Dalu Power Plant DN7800mm*210000mm

FRP flue:

The basic principle of "FRP flue" is to lift the wet flue gas after desulfurization by using the huge amount of hot air in the cooling tower, and lift the mixed gas to the air dozens of meters to 100 meters higher than the cooling regulation, so as to promote the improvement of the ground environmental quality. The technology mainly applies the glass fiber reinforced plastic horizontal flue, "smoke tower in one" of the horizontal flue is usually required to have the characteristics of corrosion resistance, large span, large diameter, because the glass fiber reinforced plastic can be designed very strong, through reasonable design, glass fiber reinforced plastic flue can better meet the above requirements. With good corrosion resistance, long life, cost saving, large span, light weight characteristics.

General process of FRP flue installation:

Flue bound - crane specified location plan calls for you to get a - a car adjustment, assembling heavy telescopic jib, hook, hoisting ready - a lifting 200 mm from the ground, try hanging, security check - officially lifting, slowly up the hook, hanging from prefabricated field, then drag roller, installation of sliding bearing, deflection, rotation, translation, fall hook base 200 mm from the center - flue Horizontal movement, two cranes at the same time, safety inspection, rotary - crane amplitude to the specified position, hook - telescopic boom, disassembly counterweight - collection - crane scattering field.

FRP flue performance cases:

Dalian Ganjingzi DN5400mm*260000mm

Dalian Ganjingzi flue DN5400mm*260000mm

Sanhe Power Plant flue DN5200mm*720000mm

FRP desulfurization tower:

Now with the development of glass fiber reinforced plastic technology, desulfurization tower is gradually changed to glass fiber reinforced plastic manufacturing. Compared with granite desulphurization tower, glass fiber reinforced plastic desulphurization tower has low cost, easy processing, no rust, light weight, so it becomes the development trend of desulphurization tower in the future. In addition, 316L stainless steel has three advantages of corrosion resistance, high temperature resistance and wear resistance, which is also one of the important trends in the development of desulfurization tower. The large desulphurization device for flue gas desulfurization is called desulphurization tower, while the small desulphurization and dust removal device for flue gas desulfurization of coal-fired industrial boilers and kilns is called desulphurization dust collector.

At present, there are three kinds of anticorrosive materials commonly used in desulphurization tower in China:

A carbon steel lining glass steel, glass flake or rubber lining and other materials, these materials because of poor wear resistance and the material inflammatory expansion coefficient is different, often appear lining off, damage phenomenon, resulting in corrosion failure;

The second is ceramic material, and this material cannot resist the corrosion of gas in the flue gas;

The third is stainless steel material with good corrosion resistance, but this material can not resist the long-term corrosion of sulfur dioxide, gas and chlorine in flue gas under high temperature conditions;

Hebei Shijiazhuang, a heating station for boiler flue gas desulfurization absorption tower, using lining glass sheet anticorrosive material, glass flake began to fall off during the adjustment, resulting in carbon steel shell corrosion leakage, had to suspend production for repair. After that, a heating season was repaired several times, and the desulphurization unit could not operate normally on and off. In flue gas desulfurization engineering, there are too many examples that the desulfurization device is corroded and cannot run normally due to improper anticorrosion measures.

At present, liusteel, Shigang, Pangang and other iron and steel enterprises have installed desulphurization equipment, the corrosion of desulphurization tower has affected the normal operation of enterprises. In some enterprises, serious corrosion occurs in desulfurization towers less than half a year after operation. If they are not repaired or replaced in time, major production accidents will occur, resulting in the running, bubbling, dripping and leaking of harmful substances, and bringing new stains to the environment.

Our successful production of glass fiber reinforced plastic desulfurization tower, because of its high temperature resistance, corrosion resistance, long service life and other advantages, widely used in electric power, non-ferrous metal industry.

Shower pipe,FRP shower pipe used in the circulation of gypsum slurry in the absorption tower, and the nozzle and spray slurry, to achieve the effect of reaction with sulfur dioxide and other chemical media in the flue gas.

Technical characteristics: corrosion resistance: epoxy vinyl ester resin is used as the lining of the pipeline to resist the erosion of sulfur containing gas and liquid in thermal power plants. Heat resistance: the pipe lining resin is epoxy vinyl ester resin with HDT(thermal deformation temperature) of 110℃, and the instantaneous temperature resistance can reach 220℃. Wear resistance: the pipe is made with wear-resisting filler, and the inner and outer surface layers are smooth and low roughness coefficient, excellent wear resistance in the solid content of 15% liquid, thermal shock resistance: FRP made of epoxy vinyl resin has good thermal shock resistance, which can avoid stratification under the thermal shock condition when the temperature reaches 200℃.

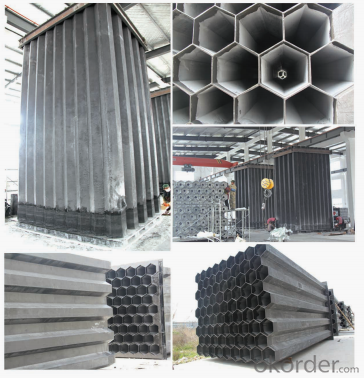

FRP Wet electrostatic dust removal:

Compared with PVC material, the advantages are as follows:

1. High temperature resistance and strong adaptability;

2. Strong electrical conductivity and high defogging efficiency;

3. High strength, light weight, saving the cost of supporting platform;

4. No welding one-time forming, no easy cracking deformation, short production and installation cycle;

5. Flame retardant performance consumption;

6 long service life.

Compared with two-way stainless steel material, the advantages are as follows;

1. One-time investment saving;

2. Light weight, saving the cost of supporting platform;

3. Compact structure and small footprint;

4. No welding one-time molding, processing and production of small difficulty, short cycle.

Quality policy:

Zhongfu Lianzhong Group took the lead in the domestic counterparts through the ISO9001:2000 quality management system certification. Every step of the production of Zhongfu Lianzhong is under strict control, from raw materials into the factory to products leaving the factory. These control processes generally include raw material testing, production, process control and finished product testing and other three main parts.

Zhongfu Lianzhong Group has the first-class physical and chemical laboratory in the industry, with more than 100 sets of various testing equipment, the industry's only computer-controlled large-caliber pipeline testing machine, Germany imported magnetic thickness gauge, etc., can be in accordance with DIN, ASTM, AWWA, BS, JIS and domestic standards and the physical properties of the raw material inspection and product inspection, such as internal pressure blasting test, the stiffness test, thermal test, thermal deformation temperature testing, the viscosity of the resin test, chemical test, glass fiber strength test and A series of experiments, the lab grade A "by chemical laboratory.

Service concept:

In accordance with the requirements of 2000 edition IS09001 quality management system, Lianyungang Zhongfu Lianzhong Composite Material Group Co., Ltd. takes customers as the focus, establishes a timely feedback, fast in place, well-equipped, excellent technology service system, and truly achieves "sincere, warm, efficient and thoughtful".

Perfect pre-sales service

As long as you a phone, a fax or an E-mail, we will quickly give you a satisfactory reply according to your requirements, if you are interested in our products, you are welcome to visit our company, we will serve you wholeheartedly.

Thoughtful sales, after - sale service

In order to ensure the scientific installation and maintenance of FRP products, we can provide free technical training to the technicians and construction personnel of construction units according to the requirements of users. According to the progress of the project, our company will send high-quality technicians to provide free on-site construction technical guidance and technical services. During the warranty period, the product quality is not caused by human, our company is responsible for free maintenance; After the end of the warranty period, lifelong maintenance, paid to provide accessories. Discount charge appropriate repair fee. Lianyungang city service arrived on the same day, jiangsu province service within 24 hours to arrive, the national service within 48 hours to arrive.