Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:350 m.t./month

TPU raw materials:

1. various kinds

2. competitive price

3. 30 years of experience

4. stable quality

TPU raw materials:

1. Applications and cable specifications of TPU raw materials:

Used for water-resistant power cables, data cables, and spring wire.

2. Description of TPU raw materials:

Environmental friendly halogen-free TPU cable compound, based on TPU elastomer resin, is made into granules by mixing, plastification and granulation with adding special modifier and other special additives. It has well performance of tenacity, scratch-resistant, flexibility, Stretch Resistance, and temperature resistance, owning exquisite appearance and smooth surface. It does not contain halogens and heavy metal, in line with the environmental directives of RoHS, REACH. Different hardness can be customized according to customers’ requirements.

3. Processing of TPU raw materials:

The compound can be processed with conventional extruders. It is recommended that the screw L/D should be greater than 25 and compression ratio should be 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Neck | Head | Die |

temperature °C | 150 | 170 | 155 | 175 | 178 | 178 | 175 |

Note:Compound should be dried at 80-90°C before use, which has stayed in storage more than one month.

4. Storage and transport of TPU raw materials:

Packaging:25kg/bag,Aluminum foil and PE film bag inside, and PP compound bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties of TPU raw materials:

Item | Unit | E7385 | E8385 | E8685 | E8685F | ||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.19 | -- | 1.21 | -- | 1.28 | -- | 1.27 |

Hardness | Shore A | -- | 85 | -- | 85 | -- | 85 | -- | 85 |

Tensile Strength | ≥MPa | 18 | 22 | 22 | 28 | 20 | 25 | 20 | 24 |

Elongation at Break | ≥ % | 550 | 700 | 500 | 650 | 500 | 650 | 450 | 600 |

Thermal aging | °C*h | 136°C*168h | 136°C*168h | 121°C*168h | 121°C*168h | ||||

TS retention | ≥ % | 75 | 103 | 75 | 105 | 75 | 104 | 75 | 102 |

EB retention | ≥ % | 75 | 81 | 75 | 84 | 65 | 89 | 65 | 86 |

Hot deformation | 150°C*4h | 150°C*4h | 150°C*4h | 150°C*4h | |||||

Variation on thermal deformation | ≤ % | 50 | 12 | 50 | 7 | 50 | 6 | 50 | 6 |

pH value of gases released | ≥ | 4.3 | 56. | 4.3 | 5.3 | ||||

Conductivity of Gases released | ≤μm/mm | 10 | 1.2 | 10 | 1.3 | ||||

Impact Brittleness Temperature | ≤ °C | -60 | Pass | -55 | Pass | -50 | Pass | -50 | Pass |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 2.1×1013 | 1.0×1013 | 5.2×1014 | 1.0×1013 | 3.4×1014 | 1.0×1013 | 1.8×1014 |

Flame retardant grade | UL94 2mm | V0 | pass | V0 | pass | ||||

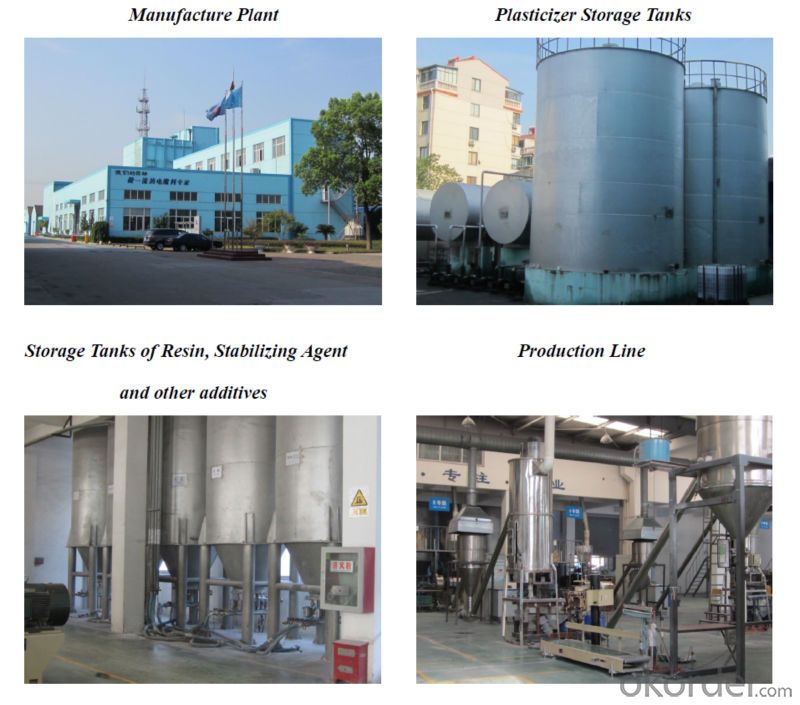

6. Company