Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:350 m.t./month

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Used as special jacket for railway, locomotive, and communication optical cables etc, of which operation temperature is at 125 degree C.

2. Descriptionof Nylon compound:

Safe environmental friendly flame retardant nylon jacket compound, based on nylon resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

temperature °C | 220 | 240 | 245 | 245 | 240 | 240 |

Note:Compound should be dried at 100°C before use, if it was stored more than one months.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA5001 | PA4001 | ||

Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.22 | -- | 1.25 |

Hardness | Shore D | -- | 68 | -- | 68 |

Tensile Strength | ≥MPa | 30 | 62 | 30 | 60 |

Elongation at Break | ≥ % | 200 | 260 | 200 | 250 |

Thermal Aging | °C×h | 158×168 | 158×168 | ||

TS/EB Retention | ≥ % | 75/75 | 90/85 | 75/75 | 90/88 |

Oil resistant test Immersion in ASTM2# | °C×h | 100×70 | 100×70 | ||

TS/EB Retention | ≥ % | 40/40 | 23/27 | 40/40 | 24/28 |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 1.1×1013 | 1.0×1012 | 2.3×1013 |

Oxygen Index | ≥ | 28 | 30 | 28 | 31 |

Low temperature winding | -40 | -50 | -40 | -50 | |

Dielectric strength | MV/m | --- | 24 | --- | 24 |

UL Class flame retardant | --- | VW-1 | --- | VW-1 | |

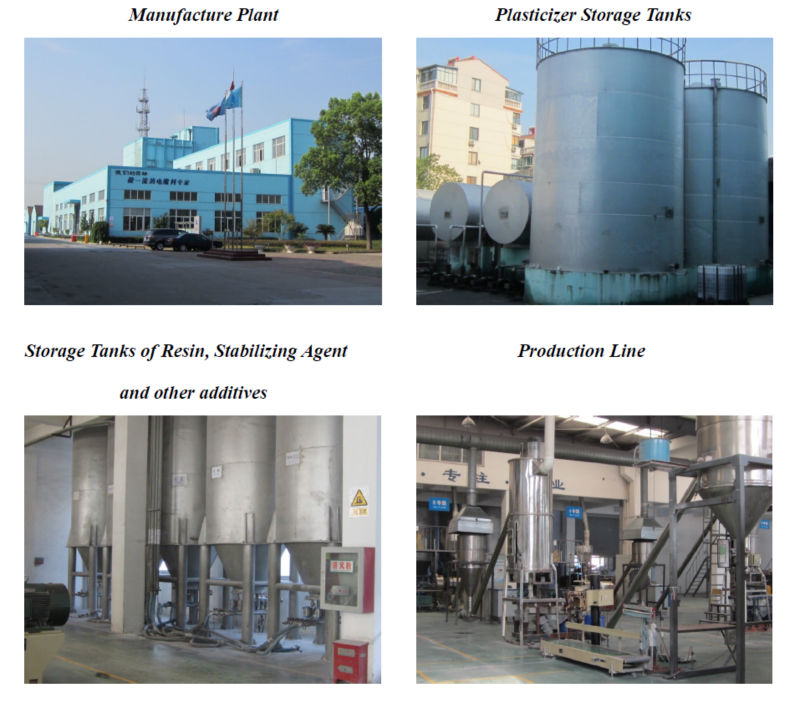

6. Company