Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Energy saving sand and stone production line

Applications of Energy saving sand and stone production line:

1. Aggregates with grain size larger than 5mm are called coarse aggregates, and there are two kinds of gravel and pebble commonly used. Particle size grading: 5-10,10-20,20-31.5.

2. The aggregate with the grain size below 5mm is called fine aggregate. According to theproduction of sand is divided into natural sand and machine-made sand.

3. Aggregates as the main raw material in concrete because of its good hardness and stability of chemical properties ,It is play a role of the skeleton and support in the building. Widely used in housing, roads, roads, railways, engineering and other fields.

4. Sand and stone production line with high capacity can be used for hard limestone, granite, basalt, river gravel, smelting slag and

other materials, aggregate and artificial sand making operations,for Hydropower Station, building materials, highways, urban construction and other industries.

5.According to different process requirements, various types of equipment combined to meet customer's different process requirements.

Brief introduction of Energy saving sand and stone production line:

1.Energy saving sand and stone production line with high capacity can be simply summarized as crushing and sorting, mainly from the conveyor, feeding, crushing, screening, sand and other aspects of aggregate production line introduced aggregate.

2.The choice of crushing equipment depends on the characteristics of ore raw materials, the local market demand for gravel products and production capacity of the production line.

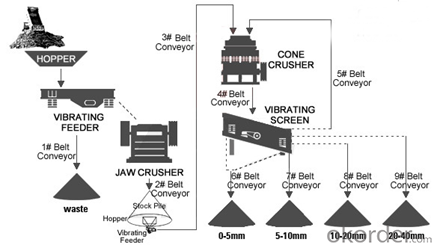

3. Energy saving sand and stone production line production process is as follows:

a.Large stone by the silo by the vibrating feeder evenly sent to the jaw crusher for coarse crushing, coarse crushed stone by the conveyor belt to the impact crusher for further crushing.

b.Crushed stone by the belt conveyor Sent to the vibrating screen for screening, screening out several different specifications of the stone, meet the requirements of the size of the stone conveyor belt conveyor, the finished product sent to finished heap.

c.Do not meet the requirements of stone by the conveyor belt back to the impact crusher to break again to form closed-loop multiple cycles.

d.Finished particle size can be combined in accordance with the needs of users and grading, to protect the environment, can be equipped with auxiliary dust removal equipment.

Advantages of Energy saving sand and stone production line:

1.The shape of the final product, with excellent quality.

2.Mud and powder content can be controlled.

3.This sand production line has the characteristics of high automation, low operating cost, high crushing rate, high productivity, and little pollution, etc. It is energy saving and is convenient to maintain.

4.Sand made by our sand production line is of equal size, good shape and reasonable distribution, complying with national building sand standard.

5.Due to reasonable matching of different levels of crushing machines spatial arrangement, our crushing and screening plant has the features of small floor space, high economic efficiency. The crushed stones are of high quality, and the output rate of stone powder is low.

6. Meanwhile, our sand production line is equipped with electronic control system which ensures smooth discharging, reliable performance, high efficiency and energy conservation.

7.Our senior engineers design each production line according to different customers.

Energy saving sand and stone production line Main Equipment Model/Specification/Quantity:

Maximum Feeding Size(mm) | Capacity(t/h) | Vibrating Feeder | Jaw Crusher | Fine Crushing Equipment (Impact Crusher) | Vibrating Screen | Conveyor Equipment(m) | Installed Power(KW) | |

340 | 30 | GZD2511(3kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1236(15kw) | 60-90(20kw) | 120 | |

340 | 50 | GZD3117(10kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1545(22kw) | 100-130(30kw) | 140 | |

420 | 80 | GZD3617(10kw) | PE500×750(55kw) | PF1010(75kw) | 3YZ1548(22kw) | 130-160(30kw) | 200 | |

480 | 100 | GZD4321(13kw) | PE600×900(75kw) | PF1210(130kw) | 3YZ1548(22kw) | 140-180(40kw) | 280 | |

560 | 150 | GZD4321(13kw) | PE750×1060(90kw) | PF1210(130kw) | 3YZ1845(22kw) | 200-240(50kw) | 300 | |

630 | 200 | GZD4321(13kw) | PE900×1060(110kw) | PFB1212(140kw) | 3YZ2050(30kw) | 200(40kw) | 350 | |

630 | 250 | GZD5027(17kw) | PE900×1060(110kw) | PFB1214(180kw) | 3YZ2050(30kw) | 200(40kw) | 400 | |

630 | 300 | GZD5027(17kw) | PE900×1200(110kw) | PFB1214(180kw) | 3YZ2160(30kw) | 250(50kw) | 450 | |

700 | 350 | GZD5027(17kw) | PE1000×1200(132kw) | PFB1315(250kw) | 3YZ2160(30kw) | 250(50kw) | 500 | |

700 | 450 | GZD6223(28kw) | PE1000×1200(132kw) | PFB1214/2(300kw) | 3YZ2145/2(60kw) | 350(60kw) | 600 |

If you want the stone production line, please tell me:

1) the raw stone material you want to crush

2) the raw stone material size

3) the final discharging size you request.

4) the capacity.