Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:50 m.t.

Supply Capability:25000 m.t./month

1.Structure of Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Description

Also known as chromed steel, tin-free steel (TFS) is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.

The product complies with ASTM A-657 Specification and is manufactured with low current density (TFS-III) and is supplied in coils (up to 12 metric tons)or sheets.

2.Main Features of the Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Solderability and weldability – Tinplates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

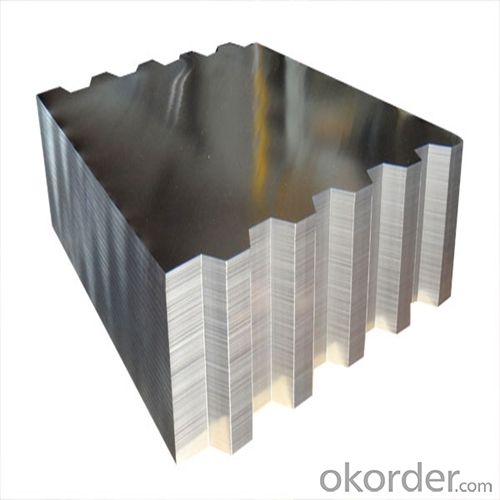

3.Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Images

4.Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D