Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:5 unit/month

Specification & Features:

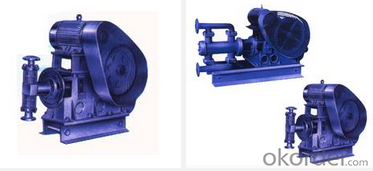

WBR high temperature reciprocating pump is the unit specifically for oil refining, paper, linoleum, petrochemical and other industries to design a new production of pumps, the pump design, compact structure, referring to the digestion and absorption of foreign products. Is a very promising delivery device using the pump for steam reciprocating pump some users are still using, is an energy-efficient, environmentally friendly substitute products. The pumps are suitable for hot water at a temperature between 150 an 400 ℃, the hot oil or other physical and chemical properties similar to water temperatures media.

Applications:

WB electric reciprocating pump machine base is divided into 1 # 2 # 3 #, reduction gear box with two speed belt, with splash lubrication mode, compact, advanced design, stainless steel pump piston rings using the unit a special bowl poly tetrafluoroethylene ring, wear, corrosion, sealing well. The high pressure pump plunger type with double valve structure, low pressure type with piston valve structure, the design is sensitive, reliable closed. Depending on the flow and pressure, equipped with different motors, can achieve the requirements of users.

Materials:

WBR high temperature reciprocating pump made of cast steel structure composed of a double jacket, the jacket can pass vapor to enter the insulation (such as heavy class), valve structure used ball way, reliable sealing, quick action. Between the head and the cabinet separated cooling jacket, apply water cooling loop mode, effectively blocking the pump head heat diffusion to the housing portion. WBR high temperature reciprocating pump seal packing. Using the most advanced high-temperature graphite fiber packing, other parts are made of heat-resistant steel and aging treatment, to ensure that the WBR high temperature reciprocating pump life.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.