Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1000 m²

Supply Capability:500000 m²/month

Self-adhesive polymer modified bitumious waterproofing membrane using polymer modified bitumen adhesive material as main material(internal could have reinforcement),double or single coated with silicone oil isolating membrane or isolating paper as antiseize

II. Product Categories:

Reinforcement: no reinforcement (N) polyester (PY)

Top surface of N type: polyethylene (PE), polyester (PET), double sides adhesive without film (D).

Top surface of PY type: polyethylene (PE), sand(S), double sides adhesive without film (D).

Performance of Material: I & II. Thickness of 2.0mm of PY only have I type.

III. Product features:

The construction of the membrane is concise and environmental: without firing, remove the isolation can adhesive at the basic tightly, it's environmental and economic.

2. Good elongation and elasticity, so it could adapt to deformation and cracking of basic well.

3. The membranes adhesive performance with basic is excellent, can avoid running water.

4. The self-healing is strong. the adhesive layer can heal automatically to protect waterproof layer in the case of puncturing.

IV. Applicable scope:The waterproof membrane is suitable for industrial and civil roofing, basement, indoor, municipal engineering, reservoirs, swimming pool, subway, road and tunnel. It also used in wood and metal roofing especially suitable for oil depot, chemical factory, textile mill, granary etc.

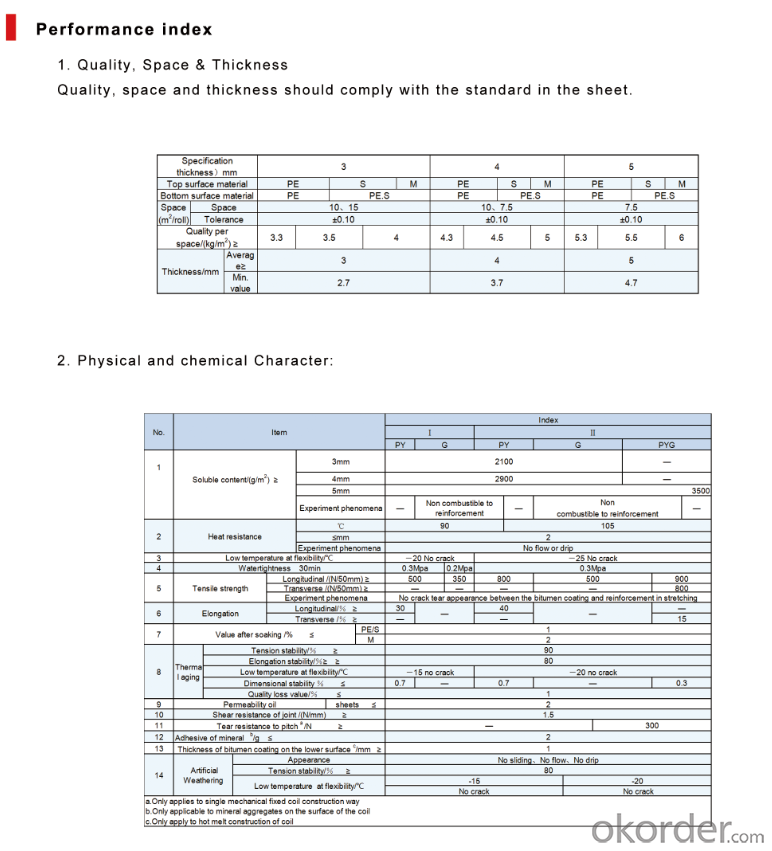

V. Performance index:

Physical and chemical Character of N type

No. | Item | Index | ||||||

PE | PET | D | ||||||

I | II | I | II | |||||

1 | Tensile strength | Tension(N/50mm) ≥ | 150 | 200 | 150 | 200 | -- | |

Longitudinal/% ≥ | 200 | 30 | -- | |||||

Bitumen elongation/% ≥ | 250 | 150 | 450 | |||||

Stretch phenomenon | Before membrane cracking no crack tear appearance between the bitumen coating and membrane in stretching | |||||||

2 | Tear resistance to pitch/N ≥ | 60 | 110 | 30 | 40 | -- | ||

3 | Heat resistance℃ | 70℃ sliding no more than 2mm | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | -20 | -30 | -20 | ||

No crack | ||||||||

5 | Watertightness | 0.2Mpa ,120Min | -- | |||||

6 | Peel strength N/mm ≥ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil | 2 | ||||||

9 | Holding power | 20 | ||||||

10 | Thermal aging | Tension stability/% ≥ | 80 | |||||

maximum tension elongation/% ≥ | 200 | 30 | 400 | |||||

Low temperature at flexibility/℃ | -18 | -28 | -18 | -28 | -18 | |||

No crack | ||||||||

Peel strength coil and aluminum plate N/mm ≥ | 1.5 | |||||||

11 | Heat stability | Appearance | No drum,fold,sliding,flow | |||||

Dimensional stability/%≤ | 2 | |||||||

Physical and chemical Character of PY type products

No. | Item | Index | ||||||

I | II | |||||||

1 | Soluble content/(g/㎡) | 2.0mm | 1300 | -- | ||||

3.0mm | 2100 | |||||||

4.0mm | 2900 | |||||||

2 | Tensile strength |

| 2.0mm | 350 | -- | |||

3.0mm | 450 | 600 | ||||||

4.0mm | 450 | 800 | ||||||

Maximun tension elongation/% ≥ | 30 | 40 | ||||||

3 | Heat resistance | 70℃ no sliding、no flow、no drip | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | |||||

No crack | ||||||||

5 | Watertightness 30min | 0.3MPa,120min | ||||||

6 | Peel strength/ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil/ amount of sheets ≤ | 2 | ||||||

9 | Holding power/min ≥ | 15 | ||||||

|

| maximum tension elongation/% | 30 | 40 | ||||

Low temperature at flexibility | -18 | -28 | ||||||

Peel strength Coil and aluminum plate/(N/mm)≥ | 1.5 | |||||||

Dimensional stability/% ≤ | 1.5 | 1.0 | ||||||

11 | Self-adhesive bitumen peel strength/(N/mm) ≥ | 1.5 | ||||||

Product Description

Construction Process

Test Machines

Certificates

Company Information