Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:1000 kg

Supply Capability:1000000 kg/month

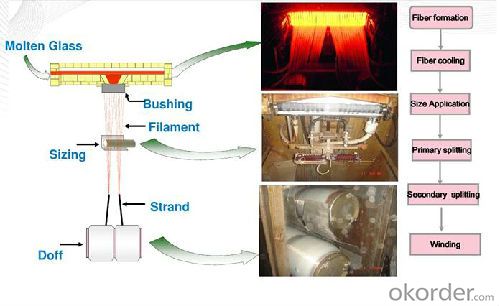

Product introduction E Glass Direct Roving for Filament Winding

386 Direct Roving is coated with a silane-based sizing compatible with unsaturated polyester, vinyl ester, and epoxy resins. It is designed for filament winding, pultrusion, and weaving applications.

386 is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven roving converted from it is used in boats and chemical storage tanks.

Specification for E Glass Direct Roving for Filament Winding

PRODUCT NAME | E-GLASS FIBER DIRECT ROVING | |

TEST ITEM | STANDARD NO. | STANDARD VALUE |

LINEAR DENSITY(TEX) | ISO 1889 | ±5% |

loi (%) | iso 1887 | 0.55±0.15 |

tensile strength (n/tex) | iso 3341 | ≥0.4 |

moisture CONTENT (%) | iso 3344 | ≤0.10 |

Features for E Glass Direct Roving for Filament Winding

A. Rapid and complete wet out

B. Good abrasion resistance

C. Good processing characteristics

D. Low resin demand during processing

E. High composite mechanical properties

F. Multi-compatible sizing

Package for E Glass Direct Roving for Filament Winding

It is available in small,single doff carton boxes but are generally palletized. Individual doffs nominally weigh 15.6kg or 22kg..

In the case of palletizing,each package is wrapped in shrink plastic film, each pallet contains 3 or 4 layers with 16 packages,totaling 48 or 64 doffs per pallets. All pallets are stretch wrapped and strapped. The way of splicing dependent upon customer requirements.

Storage for E Glass Direct Roving for Filament Winding:

Unless otherwise specified, fiberglass product should be stored in a cool, dry rain-proof area.it is recommended that the room temperature and the relative humidity be always maintained between 15-35 ℃ and 3565% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than 3 layers high. When the pallets are stacked in 2 or 3 layers,care should be taken to correctly and smoothly remove the top pallet.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. What is the Production Lead Time?

10*20GP each day.

7, Main characterisics

High tesnile strength.