Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:1 Ton m.t.

Supply Capability:50,000 Ton Per Year m.t./month

Specification:

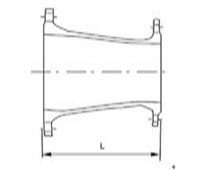

Double Socket Taper

K12

Available in T Type and K Type;

Size: DN80-2000

We are involved in the manufacture and supply of the Double Socket Taper. We manufacture these with the premium quality raw materials. Our Double Socket Tapers ensure high durability and strength. Our range of Double Socket Tapers caters to various industrial requirements. We offer these Double Socket Tapers in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter | L | Mass(kg) | ||

DN | dn | T Type | K Type | |

100 | 80 | 90 | 8.5 | 12.5 |

150 | 80 | 190 | 13.5 | 18.6 |

150 | 100 | 150 | 13.8 | 19.1 |

200 | 100 | 250 | 20.5 | 26.0 |

200 | 150 | 150 | 21 | 27.0 |

250 | 150 | 250 | 29 | 36.0 |

250 | 200 | 150 | 29 | 35.0 |

300 | 150 | 350 | 39.5 | 50.0 |

300 | 200 | 250 | 39.5 | 49.0 |

300 | 250 | 150 | 38.5 | 47.5 |

350 | 200 | 360 | 52 | 62.5 |

350 | 250 | 260 | 51 | 61.0 |

350 | 300 | 160 | 49.5 | 61.5 |

400 | 200 | 460 | 62 | 78.0 |

400 | 250 | 360 | 66 | 76.5 |

400 | 300 | 260 | 64 | 80.1 |

400 | 350 | 160 | 62 | 78 |

450 | 250 | 460 | 89.5 | 94.0 |

450 | 300 | 360 | 88.1 | 97.1 |

450 | 350 | 260 | 86 | 95 |

450 | 400 | 160 | 83.1 | 92 |

500 | 300 | 460 | 97 | 114 |

500 | 350 | 360 | 98 | 115 |

500 | 400 | 260 | 94 | 111 |

500 | 450 | 160 | 99.5 | 106 |

600 | 350 | 560 | 151 | 159 |

600 | 400 | 460 | 142 | 156 |

600 | 450 | 360 | 149 | 151 |

700 | 500 | 260 | 131 | 145 |

700 | 400 | 680 | 226 | 215 |

700 | 450 | 580 | 225 | 210 |

700 | 500 | 480 | 194 | 203 |

700 | 600 | 280 | 178 | 184 |

800 | 450 | 780 | 295 | 278 |

800 | 500 | 680 | 288 | 285 |

800 | 600 | 480 | 252 | 257 |

800 | 700 | 280 | 229 | 236 |

K12

Available in T Type and K Type;

Size: DN80-2000

Nominal Diameter | L | Mass(kg) | ||

DN | dn | T Type | K Type | |

900 | 500 | 880 | 360 | 358 |

900 | 600 | 680 | 341 | 339 |

900 | 700 | 480 | 318 | 327 |

900 | 800 | 280 | 288 | 294 |

1000 | 600 | 880 | 446 | 445 |

1000 | 700 | 680 | 427 | 422 |

1000 | 800 | 480 | 392 | 403 |

1000 | 900 | 280 | 354 | 368 |

1200 | 700 | 1080 | 699 | 667 |

1200 | 800 | 880 | 668 | 631 |

1200 | 900 | 680 | 630 | 591 |

1200 | 1000 | 480 | 570 | 580 |

1400 | 800 | 760 | 877 | 716 |

1400 | 900 | 660 | 906 | 710 |

1400 | 1000 | 560 | 1015 | 704 |

1400 | 1200 | 360 | 711 | 698 |

1600 | 1000 | 760 | 1427 | 960 |

1600 | 1200 | 560 | 1355 | 919 |

1600 | 1400 | 360 | 951 | 936 |

1800 | 1200 | 760 | - | 1238 |

1800 | 1400 | 560 | - | 1198 |

1800 | 1600 | 360 | 1235 | 1234 |

2000 | 1200 | 960 | - | 1620 |

2000 | 1400 | 760 | - | 1579 |

2000 | 1600 | 560 | - | 1503 |

2000 | 1800 | 360 | 1566 | 1565 |

Double Flanged Taper

K12

Concentric and Flat Type

PN10, PN16 and PN25 are available

Size: DN80-2000

We are involved in the manufacture and supply of the Double Flanged Taper. We manufacture these with the premium quality raw materials. Our Double Flanged Tapers ensure high durability and strength. Our range of Double Flanged Tapers caters to various industrial requirements. We offer these Double Flanged Tapers in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter | Length | Mass(kg) | |||

DN | dn | L | PN10 | PN16 | PN25 |

100 | 80 | 200 | 9.5 | 9.5 | 9.8 |

150 | 80 | 400 | 15.2 | 15.2 | 16.2 |

150 | 100 | 300 | 15.5 | 15.5 | 17 |

200 | 100 | 600 | 29.5 | 28 | 30.8 |

200 | 150 | 300 | 22 | 21.5 | 25.0 |

250 | 150 | 600 | 43 | 42.5 | 46.7 |

250 | 200 | 300 | 30 | 29.5 | 35.5 |

300 | 150 | 600 | 56 | 55 | 62 |

300 | 200 | 600 | 58.5 | 57 | 65 |

300 | 250 | 300 | 40.5 | 39.5 | 49.5 |

350 | 200 | 600 | 60.5 | 63.5 | 74.0 |

350 | 250 | 600 | 67 | 70 | 82.5 |

350 | 300 | 300 | 49.5 | 52 | 66.0 |

400 | 200 | 600 | 74.5 | 73 | 86.5 |

400 | 250 | 600 | 77.0 | 83 | 98.5 |

400 | 300 | 600 | 82 | 90 | 107 |

400 | 350 | 300 | 58 | 67.0 | 86.0 |

450 | 250 | 600 | 82 | 87 | 103 |

450 | 300 | 600 | 87 | 92 | 110 |

450 | 350 | 600 | 96 | 106 | 125 |

450 | 400 | 300 | 81 | 85 | 101 |

500 | 300 | 600 | 126 | 134 | 152 |

500 | 350 | 600 | 117 | 125 | 150 |

500 | 400 | 600 | 110 | 130 | 153 |

500 | 450 | 300 | 83.0 | 104 | 127 |

600 | 350 | 700 | 167 | 188 | 226 |

600 | 400 | 600 | 164 | 191 | 229 |

600 | 450 | 600 | 167 | 193 | 221 |

600 | 500 | 600 | 195 | 210 | 216 |

700 | 400 | 800 | 196 | 212 | 255 |

700 | 450 | 700 | 197 | 217 | 259 |

700 | 500 | 600 | 200 | 256 | 268 |

700 | 600 | 600 | 195 | 236 | 282 |

800 | 450 | 900 | 263 | 286 | 347 |

800 | 500 | 800 | 256 | 284 | 346 |

800 | 600 | 600 | 260 | 298 | 363 |

800 | 700 | 600 | 263 | 290 | 371 |

900 | 500 | 1000 | 338 | 370 | 443 |

900 | 600 | 800 | 318 | 360 | 436 |

900 | 700 | 600 | 321 | 352 | 444 |

900 | 800 | 600 | 308 | 352 | 462 |

1000 | 600 | 1000 | 422 | 490 | 583 |

1000 | 700 | 800 | 396 | 442 | 551 |

1000 | 800 | 600 | 399 | 448 | 575 |

1000 | 900 | 600 | 376 | 438 | 577 |

1200 | 700 | 1260 | 711 | 777 | 908 |

1200 | 800 | 1070 | 688 | 758 | 908 |

1200 | 900 | 880 | 652 | 726 | 887 |

1200 | 1000 | 790 | 586 | 692 | 879 |

1200 | 1100 | 600 | 566 | 655 | 850 |

1400 | 800 | 1590 | 1034 | 1105 | 1308 |

1400 | 900 | 1405 | 998 | 1074 | 1288 |

1400 | 1000 | 1220 | 961 | 1052 | 1236 |

1400 | 1100 | 1035 | 914 | 1005 | 1253 |

1400 | 1200 | 850 | 817 | 947 | 1199 |

1600 | 1000 | 1650 | 1424 | 1547 | 1802 |

1600 | 1100 | 1460 | 1377 | 1502 | 1774 |

1600 | 1200 | 1280 | 1324 | 1468 | 1745 |

1600 | 1400 | 910 | 1103 | 1273 | 1602 |

1600 | 1500 | 725 | 1073 | 1250 | 1594 |

1800 | 1100 | 1895 | 1910 | 2057 | 2392 |

1800 | 1200 | 1710 | 1858 | 2024 | 2363 |

1800 | 1400 | 1340 | 1701 | 1870 | 2263 |

1800 | 1500 | 1155 | 1610 | 1810 | 2216 |

1800 | 1600 | 970 | 1436 | 1664 | 2081 |

2000 | 1200 | 2140 | 2512 | 2705 | 3069 |

2000 | 1400 | 1770 | 2358 | 2553 | 3059 |

2000 | 1500 | 1585 | 2268 | 2494 | 3014 |

2000 | 1600 | 1400 | 2176 | 2404 | 2934 |

2000 | 1800 | 1030 | 1800 | 2079 | 2671 |

•Material :Ductile Cast Iron

•Size Range :DN 80 to DN 2000

•Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

•Annual capacity : 50,000 tons

•Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

•Cement Interior:Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

•Special requirements on external coating and internal lining can be applied

•We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

| Packaging Detail: | package:wooden cases with plastic layer, wooden pallets with plastic layer , steel crates,steel strip |

| Delivery Detail: | within 20-30 days after receipt the 70% balance |

Usage:

It is used for the connection between the two different diameter of pipes.