Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:500 m

Supply Capability:5000 m/month

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets

accoding to ISO4633

3) Our products have been sold to many international market,

such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

•High yield strength

•High tensile Strength

•High corrosion resistance

•Installation is convenient

•Satisfy the highest hygienic standards

1. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

2. Length: 6m or cut into 5.6m, 5.7m, 5.8m

3. Internal Lining: Cement, conform to ISO4179

4. External coating: Zinc + Bitumen, conform to ISO8179

5. Rubber: NBR, SBR, EPDM according to ISO4633 / EN681.1

6. Note: The gaskets, bolts & nuts are supplied respectively as your special requirement

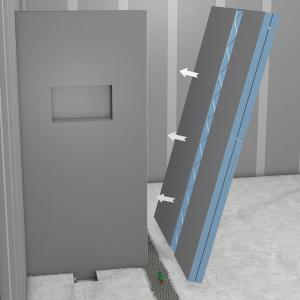

3,Ductile Iron Pipe Images:

4. Ductile Iron Pipe Specification

Surface Finishes Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap End Finishes Beveled, Square Cut, Threaded, hat Additional Services Internal Coating.

Packaging packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin,

plastic sheeting

Inspection MOODY SGS BV GL DNV ABS LIOYD’S Test X-ray, UT, magnetic particle,inspection, hydrostatic test.

Processing service Beveling, Threading, Slotting, Cut-to length, Bends, Quench and Temper, Fabrication, Double-jointing and On-site assistance

Documentary MTC, material certification,Origin certification, CI or PI,Test Report, export licence, handling order, B/L,insurance policy,shipping instructions, contract, packing list etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.