Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:20 PCS pc

Supply Capability:1000 Ton Per Month pc/month

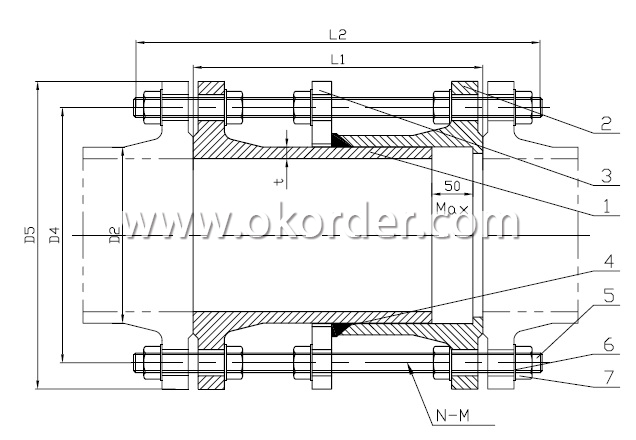

Specifications of Ductile Iron Dismantling Joint

1) Follower gland ring: Ductile Iron GGG500-7

2) Flanged Adaptor bodies: Ductil iron GGG500-7

3) F-piece pipe: Ductile iron GGG500-7

4) Bolts, Nuts and Washers Material: Carbon Steel Grade 4.8 with Zinc Coating, Epoxy Coating or Dacromet Coating; Or Stainless Steel upon customers request .

5) Tie Rods: Carbon Steel Grade 4.8 with Zinc Coating, Epoxy Coating or Dacromet Coating; Or Stainless Steel upon customers request.

6) Gaskets material:

For water or Gas: NBR Grade A.

For drinking water: EPDM rubber to BS2494:1990 type W.

For drinking water and sewage: SBR Grade F.

7) Body Coating: Fusion Bonded Epoxy Coating inside and outside, or bitumen painting upon customers requires.

8) Sizes: DN50-DN2000

9) Pressure Grade: PN10/PN16/PN25

Applications of Ductile Iron Dismantling Joint

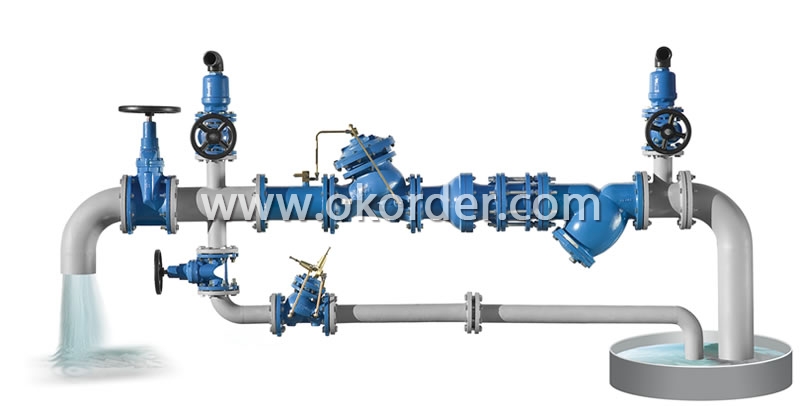

Ductile Iron Dismantling Joints are Suitable for all flanged piping materials above ground or in chamber flanges and drillings to ISO7005-2( BS EN1092-2:1997, DIN2501).

Ductile Iron Dismantling Joints are Suitable for water, sewage and neutral liquids to max.70°C .

The dismantling joint enables easy installation and dismantling of isolating valves, non-return valves, flow metering equipment, pumps etc.

Packing & Delivery of Ductile Iron Dismantling Joint

Package: Bubble plastic bags, Cartons and Wooden cases.

Delivery: By Containers for shipments, and trucks or train for inland transport.

Three Features of Ductile Iron Dismantling Joint

Developed for Complete Versatility

The Dismantling Joints are double flanged fittings that accommodate up to 100mm (4”) longitudinal adjustment and can be locked at the required length with the tie bars supplied. Not only does this system allow for fast, easy maintenance of valves, pumps or meters, it simplifies future pipe work modifications and reduces downtime when changes need to be made.

Easy to Install

The installation is also straightforward using just a spanner and torque wrench to tighten the high tensile steel or stainless steel tie bars. With fewer tie bars than flange holes and the tie bars acting as flange jointing bolts theprocess is speeded up but still offers a secure, rigid, fully endload resistant system with a pressure rating equal to that of the flange.

The Range

A comprehensive range is available from DN40 (1½”) to DN2400 (80”) with virtually any flange drilling or pressure rating supplied, although larger sizes and custom made Dismantling Joints can be designed and built on request.

If you have other question about our products, please feel free to contact us!