Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:1 Ton m.t.

Supply Capability:50,000 Ton Per Year m.t./month

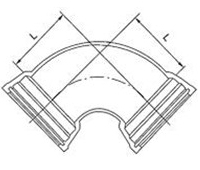

90° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 100 | 8.6 | 12.0 |

100 | 120 | 11.5 | 15.6 |

150 | 170 | 20.5 | 27.5 |

200 | 220 | 33 | 40.0 |

250 | 270 | 48.5 | 55.5 |

300 | 320 | 68 | 81.5 |

350 | 370 | 83 | 105 |

400 | 420 | 143 | 134 |

450 | 470 | 156 | 166 |

500 | 520 | 183 | 202 |

600 | 620 | 273 | 290 |

700 | 720 | 455 | 408 |

800 | 820 | 605 | 544 |

900 | 920 | 813 | 720 |

1000 | 1020 | 1045 | 935 |

1200 | 1220 | 1508 | 1444 |

1400 | 1220 | 2419 | 1918 |

1600 | 1290 | 3382 | 2543 |

1800 | 1320 | 3616 | 3229 |

2000 | 1360 | 4516 | 4033 |

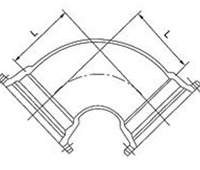

45° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 55 | 7.7 | 11.1 |

100 | 65 | 10.1 | 14.3 |

150 | 85 | 17.5 | 24.0 |

200 | 110 | 27 | 34.0 |

250 | 130 | 38.5 | 45.5 |

300 | 150 | 53 | 66.0 |

350 | 175 | 70 | 83.5 |

400 | 195 | 89 | 104 |

450 | 220 | 117 | 124 |

500 | 240 | 139 | 150 |

600 | 285 | 202 | 209 |

700 | 330 | 282 | 289 |

800 | 370 | 378 | 373 |

900 | 415 | 496 | 488 |

1000 | 460 | 635 | 628 |

1200 | 550 | 986 | 943 |

1400 | 515 | 1273 | 1223 |

1600 | 565 | 1740 | 1647 |

1800 | 610 | 2296 | 2166 |

2000 | 660 | 2970 | 2791 |

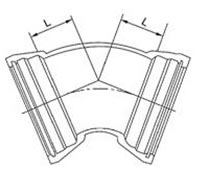

22.25° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 40 | 7.5 | 10.7 |

100 | 40 | 9.5 | 13.5 |

150 | 55 | 15.9 | 22.5 |

200 | 65 | 24 | 30.5 |

250 | 75 | 33.5 | 40.5 |

300 | 85 | 44.5 | 58.0 |

350 | 95 | 58 | 71.0 |

400 | 110 | 74 | 88.0 |

450 | 120 | 95.0 | 105 |

500 | 130 | 111 | 123 |

600 | 150 | 157 | 164 |

700 | 175 | 217 | 223 |

800 | 195 | 287 | 281 |

900 | 220 | 373 | 364 |

1000 | 240 | 470 | 463 |

1200 | 285 | 716 | 671 |

1400 | 260 | 933 | 882 |

1600 | 280 | 1259 | 1167 |

1800 | 305 | 1663 | 1533 |

2000 | 330 | 2114 | 1965 |

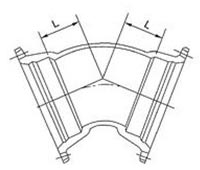

11.25° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 30 | 7.1 | 10.5 |

100 | 30 | 8.9 | 13.1 |

150 | 35 | 14.8 | 21.5 |

200 | 40 | 22 | 29.0 |

250 | 50 | 30.5 | 37.5 |

300 | 55 | 40.5 | 54.0 |

350 | 60 | 52 | 65.5 |

400 | 65 | 65 | 79.0 |

450 | 70 | 83.5 | 93.5 |

500 | 75 | 96 | 108 |

600 | 85 | 134 | 141 |

700 | 95 | 181 | 187 |

800 | 110 | 239 | 234 |

900 | 120 | 305 | 297 |

1000 | 130 | 381 | 375 |

1200 | 150 | 568 | 524 |

1400 | 130 | 747 | 697 |

1600 | 140 | 1007 | 914 |

1800 | 155 | 1331 | 1200 |

2000 | 165 | 1702 | 1522 |

Packaging Detail: | wooden cases with plastic layer , wooden pallets with plastic layer , steel strip. |

Delivery Detail: | 30days after the order confirmed. |

MATERIAL:Ductile iron grade 500-7/ 450-10 in accordance with ISO 1083.

STANDARD: ISO 2531/EN 545/EN598

FLANGE: PN10, PN16 or PN25 drilling in accordance with ISO 7005-2/EN 1092-2.

COATING:

a. Zinc coating +bitumen painting;

b. Liquid epoxy painting;

c. Epoxy applied by FBE;

d. Other coating as your requirement

Test:Dimensions and testing in accordance with ISO 2531/EN 545 and 100% water pressure test.

Note: The gaskets, bolts & nuts are supplied respectively as your special requirement.

Usage:

It is a connection is commonly used in pipe installation with fitting, connect two of the same or different nominal diameter pipes.