Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10000 set/month

Structure of DPP260H3 Aluminium Blister Foil Machine CTJF-80T Description:

New Style Discount Aluminum Foil Oval Containermaking Machine with Lid Description is semi-automatic rolling cutting equipment designed by our company. It is advanced technology ,performance stability ,simple operation and high production efficiency .HRSL650 semi-automatic electrical household aluminum foil cutting machine is mainly used in Japan Omron original encoder, Huichuan frequency controller, AIRTAC pneumatic control system in Taiwan, South Korea SBG linear guide, the East Kawasaki Electric counter. It can be set and adjust the specification freely and adjust the length automatically according to different requirement of clients. It is an ideal household foil equipment.

It's widly used in : Fast Food / Supermarket , Baking, Food container/disposable meal, box/disposable lunch box for airline ,for hotel , restaurant , bakery , supermarket , airline ,high quality , safe ,competitive

Main Features of the DPP260H3 Aluminium Blister Foil Machine CTJF-80T:

1. Materials: Aluminum Foil, good glossy environment-friendly and

recyclability

2.Various dimensions and shapes available, including rectangle,

oblong and square with hemmed and curl edge

3.Packing: Hot Shrink Packing ,Bulk Packing ,Display Box Packing

4. High temperature sterilization

5. Make the molds as customers’ requirements

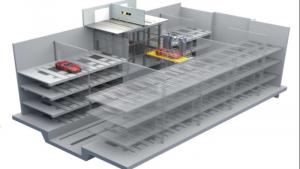

Images of the DPP260H3 Aluminium Blister Foil Machine CTJF-80T:

DPP260H3 Aluminium Blister Foil Machine CTJF-80T Specification:

| XWSL-40 | XWSL-55 | XWSL-70 | XWSL-80 | |

| Max width of Roll | 350MM | 500MM | 650MM | 750MM |

| Max Unwind Roll Diameter | 600MM | 600MM | 600MM | 600MM |

| Feeding Speed | 0-35 | 0-35 | 0-35 | 0-35 |

| Feeding Length | 20-999 | 20-999 | 20-999 | 20-999 |

| Feeding Accuracy | ±0.3 | ±0.3 | ±0.3 | ±0.3 |

| Working Vollage | 380/220 | 380/220 | 380/220 | 380/220 |

| Total Power | 1 | 1 | 1.4 | 1.4 |

| Weight of Machine | 700 | 850 | 1000 | 1150 |

| Diemension | 2000*1150*900 | 2000*1300*900 | 2000*1450*900 | 2000*1550*900 |

| Model | JF21-25 | JF21-45 | JF21-63 | JF21-80 | JF21-110 |

| Nominal Pressure (KN) | 250 | 400 | 630 | 800 | 1100 |

| Slide Block Stroke(mm) | 80-160mm | 100-260mm | 120-260mm | 140-260mm | 150-260mm |

| Slide Strock Per Minutes(min) | 90-60 | 70-50 | 70-50 | 60-45 | 50-40 |

| Max Die Set Height(mm) | 250-300 | 270-400 | 310-450 | 325-450 | 345-500 |

| Die Set Height Adjustment(mm) | 50 | 60 | 70 | 80 | 90 |

| Slide Bottom Size(MM) | 330*250 | 410*340 | 480*400 | 560*460 | 630*520 |

| Stemhole Size(MM) | 60*60 | 60*60 | 60*65 | 60*75 | 60*85 |

| Bolster Surface Size(MM) | 700*320/800*480 | 810*440/990*750 | 870*520/1000*800 | 1000*600/1200*800 | 1100*680/1300*800 |

| Total Power(KW) | 3-4 | 5.5 | 5.5-7.5 | 7.5-11 | 11-15 |

| Weight | 2800-3100 | 3800-4500 | 5500-6300 | 8000-9000 | 11000-12000 |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.