Loading Port:Lianyungang

Payment Terms:TT OR LC

Min Order Qty:0 set

Supply Capability:50 set/month

Sign of The Times:

Since the world's first gas station was born in the United States in the early 20th century, the new term "gas station" has been recorded in history. With the rapid development of the automobile industry, gas stations have sprung up like mushrooms. However, with the continuous growth of gas stations, in addition to the rapid development of the automobile industry, there are increasingly strict environmental protection requirements. Environmental pollution caused by oil leakage is an urgent problem to be solved by all countries.

At the beginning of the 1960s, Germany pioneered the double-layer tank for storing oil products, and this double-layer tank is made of steel inside and outside, known as SS double-layer

In the early 1980s, the American Steel Tank Association launched the SF double tank, which is lined with steel structure, and the outer tank wall is made of FRP and glass fiber reinforced plastic, which effectively resist the erosion from groundwater, microorganisms and soil environment in the buried environment

Subsequently, at the end of 1980s, the world's first FF double-layer tank made of BOTH inner and outer FRP materials came out in Los Angeles, USA. This dual-layer FRP storage tank solves the problems existing in previous oil tanks with metal structure, and is well adapted to the corrosion problems caused by the development of biofuels and alternative fuels in recent years. Therefore, it has been widely recognized and supported by laws and regulations, as well as third-party certification organizations such as UL

With the development of national economy and the continuous enhancement of people's awareness of environmental protection, laws and regulations related to environmental protection in China are gradually improved. The topic of environmental protection has attracted more and more attention, and the environmental protection of air, water and soil has become the focus of society. Through the "two sessions" during many environmental proposals, let us the whole society is aware of the seriousness of the problem, China has completed the "air ten" revision and "water ten" official release, and the "soil ten" is also coming out.

In the eighth article of the "Water Rule", it is required in the prevention and control of groundwater pollution that all underground oil tanks of gas stations should be upgraded to double tanks or anti-seepage ponds should be set up before the end of 2017.

Double wall FRP oil storage tank features:

As fuel and chemical containing liquids stored in underground steel tanks around the world have become more and more erosive over the past few decades, a large number of markets are moving towards using FRP tanks in addition to coating the inner surfaces of existing steel tanks. Because the permeability and compressive strength, FRP tanks from single-walled incline to double wall, both inside and outside double using enhanced glass fiber materials, has a long service life, corrosion resistance, prevent conductive, light weight, free maintenance, as well as good seismic performance, production process mainly has the short cut fiber injection method, the centrifugal casting method, winding molding process, such as double even the more than 30 years of glass fiber reinforced plastic production Product design and manufacturing experience, quality assurance let you rest assured.

Comparison table of characteristics of various double - wall storage tanks

F/F double-wall tank | S/S double-wall tank | S/F double-wall tank |

The inner and outer walls are made of FRP | The inner and outer walls are steel structural layers | Inner steel, outer FRP material |

Never rust | Easy to rust | The inner wall rusts easily |

Thick structure wall, high external pressure strength | Thick structure wall, high external pressure strength | Easy to scratch, peel or rupture |

External wall leakage can be measured by positive pressure | External wall leakage can be measured by positive pressure | The outer wall is not structural layer, can not be positive pressure leakage test |

No cathodic protection is required | External wall leakage can be measured by positive pressure | The outer wall is not structural layer, can not be positive pressure leakage test |

High voltage pinhole detection is not required | Unable to do high voltage pinhole detection | Need 35kV high voltage pinhole detection |

If found leakage can be repaired | Unable to do high voltage pinhole detection | Need 35kV high voltage pinhole detection |

The tank is light, easy to construct and cost effective | Unable to do high voltage pinhole detection | Need 35kV high voltage pinhole detection |

LZFRP production of FRP double way oil tank adopts double structure design, in the interlayer between the inner and outer wall can be installed within 24 hours of continuous monitoring system, both inside and outside wall leakage, mezzanine can be automatic induction and alarm, instant repair, put an end to the oil cause pollution to soil and underground water, in line with international environmental requirements:

1.Double - wall tank is a continuous leakage monitoring system when damaged.

2.If the inner wall of the double-wall tank is damaged or leaked, the detected liquid level in the interlayer between the inner and outer walls will drop.

3.If the outer wall of the double-wall tank is damaged or leaked, the detected liquid level in the interlayer between the inner and outer walls will also decrease.

4.If the groundwater level is higher than the detected liquid level in the sandwich and the outer wall is damaged or leaked, the detected liquid level in the sandwich will rise.

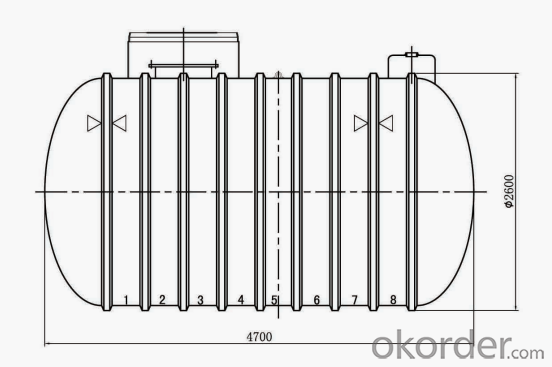

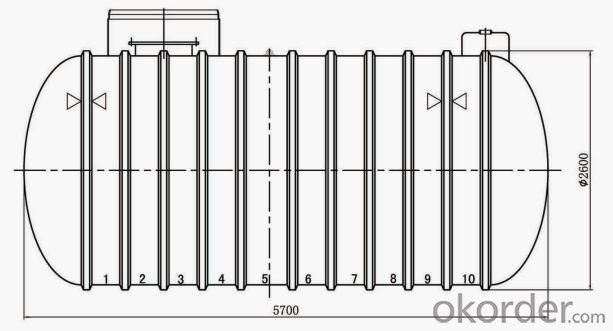

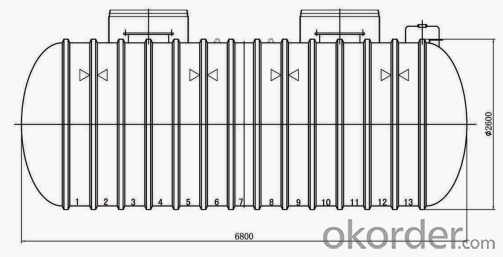

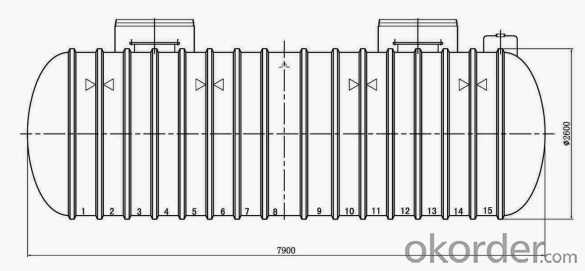

FRP double wall tank parameters table:

Item | Volume m³ | ||||||

20 | 25 | 30 | 35 | 40 | 45 | 50 | |

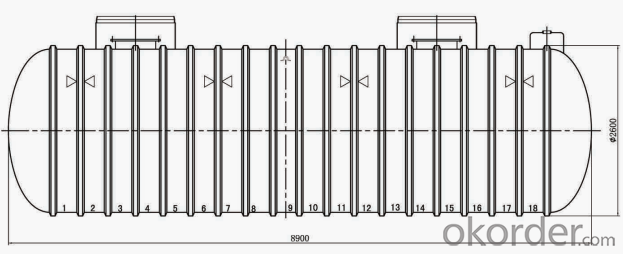

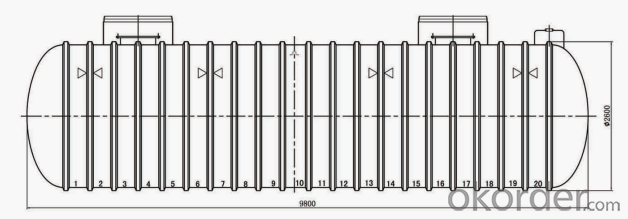

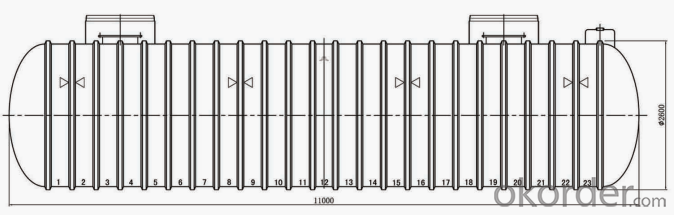

Tank length (mm) | 4600 | 5800 | 2600 | 7900 | 8900 | 10000 | 11000 |

Nominal diameter (mm) | 2600 | ||||||

Filling coefficient | 0.9 | ||||||

Manhole diameter (mm) | 600 | ||||||

Design pressure (MPa) | 0.172 | ||||||

Inner surface resistivity (Ω) | ≤109Ω | ||||||

Inner wall volume resistivity (Ω) | ≤108Ω | ||||||

Leakage detection resolution (L/h) | ≤0.8 | ||||||

Service life (years) | ≥50 | ||||||

Warranty Period (year) | 30 | ||||||

20m³FRP double wall tank

25m³FRP double wall tank

30m³FRP double wall tank

35m³FRP double wall tank

40m³FRP double wall tank

45m³FRP double wall tank

50m³FRP double wall tank

Quality assurance:

I. Comprehensive and abundant testing equipment:

LZFRP has the industry first-class physical and chemical laboratory, have all kinds of testing equipment more than 100 sets, with the industry's only microcomputer control pipe mechanical properties testing machine, Germany imports of magnetic thickness gauge, thread, differential scanning calorimeter single parameter tester, hydrostatic pressure testing machine, island ferry universal material testing machine, Instron material fatigue testing machine, the gold Like microscope, according to API, ASTM, ISO, BS and domestic standards for raw material detection and physical properties of the product inspection, such as internal pressure blasting test, long-term hydrostatic pressure failure test, cyclic pressure test, stiffness test, DSC differential thermal analysis, chemical resistance test, material mechanics test and a series of tests.

II.Enforce standards and specifications:

∙ GB/T 50156-2012 Code for design and construction of automobile refueling and filling stations

∙ GB/T 1410-2006 Test method for volume and surface resistivity of materials

∙ GB/T 13348-2009 Liquid petroleum products electrostatic safety code

∙ GB/T 50650-2011 lightning protection design code for petrochemical installations

∙ SH 3097-2000 Code for electrostatic grounding design in petrochemical industry

∙ Db11/588-2008 Technical specification for leakage prevention of buried tank

∙ JB/T 4731-2005 steel horizontal container

∙ SH/T 3177-2015 Engineering specification for buried glass fiber reinforced plastic double layer oil tank for gas station

∙ UL 1316-2006 Glass-Fiber-Reinforced Plastic Underground Storage Tanks for Petroleum Products, Alcohols, and Alcohol-Gasoline Mixtures