Loading Port:China main port

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:30 unit/month

Building Hoist Description

Condition: New

Application: Construction SC100/100

Payload(kg):2*1000

Lifting Speed(m/min):0~30

Motor Power(kw): 2*3*23

Safety Device: 2*SAJ50-1.4

Cage: Single/double cages

Counterweight: No

Certification: CE/ ISO

Place of Origin: China(Mainland)

Model Number: Type:SC100/SC100

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 12-15days

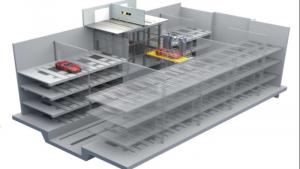

Main Parts of Building Hoist

Feature:

● microcomputer programmable logic controller.

● Adopts open loop V/Fcontrol;Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up . It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload

● The system applies the special software for hoists developed by our company, making the operation more safe

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide

Q: What is the meaning of the building hoist’s code?

A: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage

Q: What is the dimension of the cage?

A: Details should be checked according to our

quotation sheet. the size can be customized according to the factual site condition. There are two doors for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.