Loading Port:Qingdao Port

Payment Terms:TT or LC

Min Order Qty:25M.T. m.t.

Supply Capability:200000M.T./Year m.t./month

Feature of Rolling Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

1)In general, grinding steel ball has high hardness: surface hardness to 58-65 HRC, volume hardness of 56-65 HRC

2)Impact toughness high: impact toughness more than 12 J / cm2.

3)Broken rate is low: the actual broken rate is not higher than 0.5%.

4)Loss of grinding forged steel ball round rate is low.

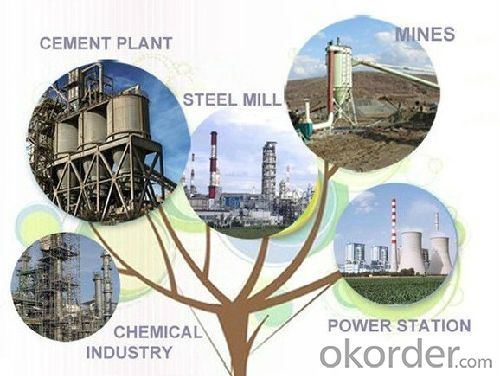

Applied fields of Rolling Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

1)Metal Mines, 2) Cement plants,

3) Power stations, 4) Chemical industry

Chemical Elements of Rolling Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

Material | C | Mn | Si | Cr | S | P | V |

50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

65Mn | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

75Mn | 0.72-0.92 | 0.17-0.37 | 0.17-0.37 | 0.4-0.6 | ≤0.035 | ≤0.035 | |

75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 | |

75SiMn | 0.70-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 | |

Wear-resistant Alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 |

Material | C | Si | Cr | Mn | S | P |

Cr-22-32% | 2.0-2.8 | ≤1.0 | 22-32 | 0.5-2.0 | ≤0.06 | ≤0.08 |

Cr-17-22% | 2.0-2.8 | ≤1.0 | 17-22 | 0.5-2.0 | ≤0.06 | ≤0.08 |

Cr-15-17% | 2.2-3.0 | ≤1.0 | 15-17 | 0.5-2.0 | ≤0.06 | ≤0.08 |

Cr-11-14% | 2.2-3.2 | ≤1.0 | 11-14 | 0.5-2.5 | ≤0.06 | ≤0.08 |