Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:5 m.t.

Supply Capability:100000 m.t./month

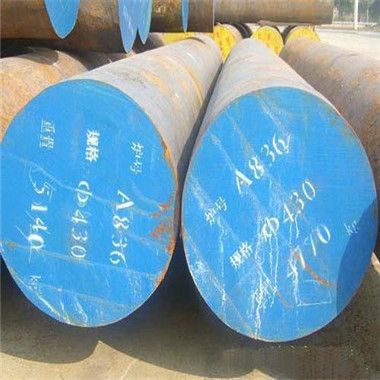

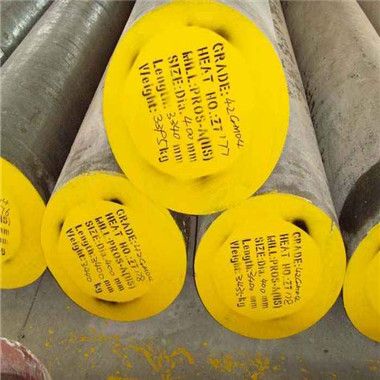

D6 Cold Work Mould Steel Round Bars DIN1.2436

AISI D6 tool steel is a high-carbon, high chromium tool steel alloyed with tungsten that is characterized by high compressive strength, high wear resistance, high surface hardness and good hardening stability

Specification of D6 tool steel

1.Diameter:60mm~600mm

2.Length:1-6.5m or as customer's request

The chemical composition of D6 tool steels is outlined in the following table.

| Element | Content (%) |

|---|---|

| Iron, Fe | 83.05 |

| Chromium, Cr | 12.5 |

| Carbon, C | 2.05 |

| Tungsten, W | 1.3 |

| Manganese, Mn | 0.8 |

| Silicon, Si | 0.3 |

D6 tool steel is heated slowly and uniformly to 700°C (1292°F) and then more rapidly to 900-1050°C (1652-1922°F).

D6 tool steel is then annealed at 800-840°C (1472-1544°F) and cooled. Hardness of the steel after annealing will be approximately 225 Brinell.

Stresses from D6 tool steel can be eliminated before hardening by heating up to 650-700°C (1202-1292°F), if machining operations have been heavy. The steel is then allowed to cool slowly.

D6 steel is pre-heated slowly to 750-800°C (1382-1472°F) and thoroughly soaked. Heating is then continued till the final hardening of 950-980°C (1742-1796°F), followed by air or oil quenching.

The steel is heated uniformly and thoroughly at the selected tempering temperature. Double tempering can also be carried out with intermediate cooling to room temperature.

Main applications of D6 tool steels:

Forming tools

Molds for abrasive plastics and ceramics

Long-run press tools

Blanking and shearing tools for hard materials.