Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:50 unit/month

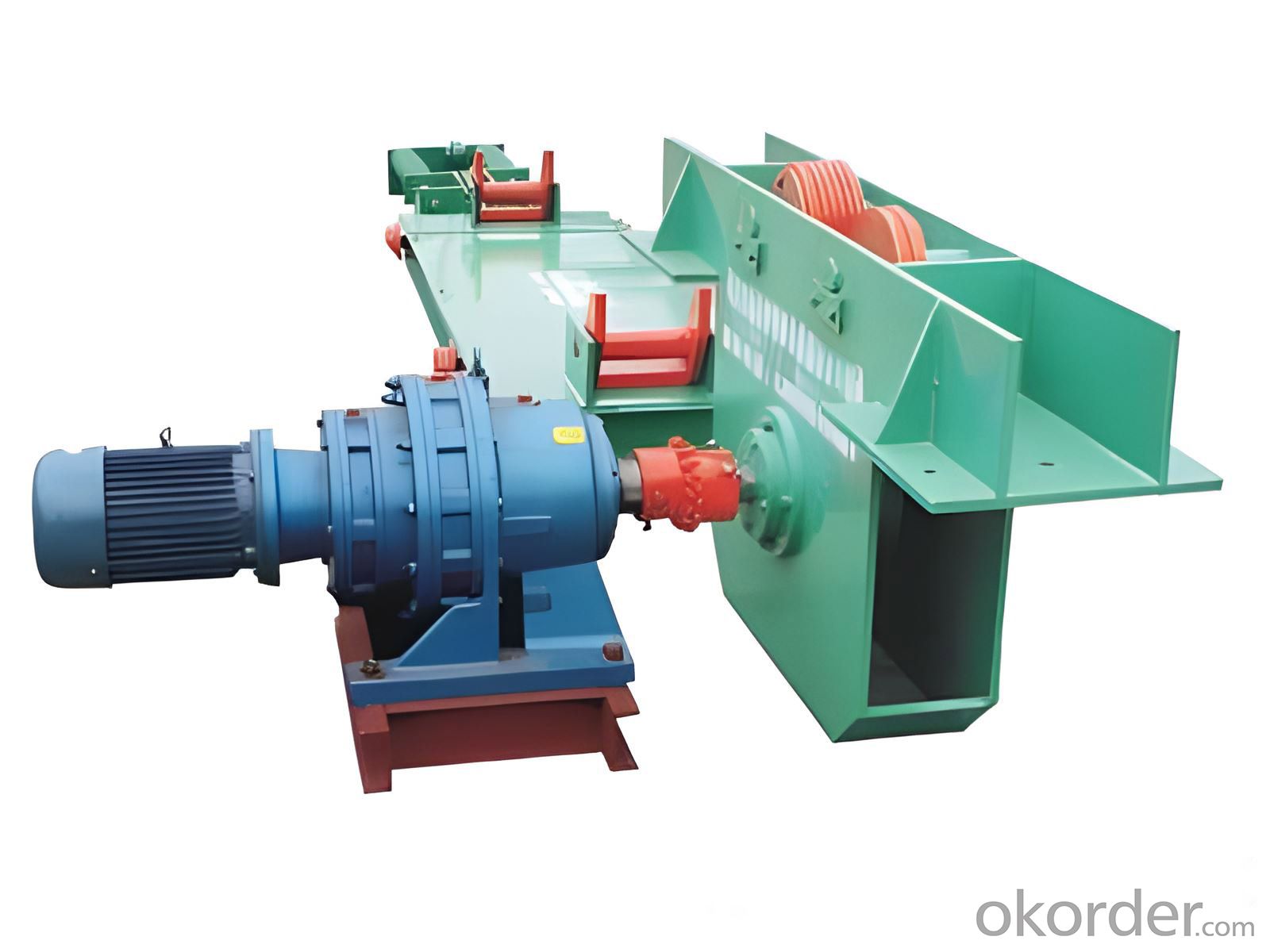

Positioning Stepper

Specifications | Max Thrust(t) | Push Speed(m/s) | Motor Power(kw) | Oil Cylinder | Applicable Kiln Type |

ZWBJ-15 | 15 | 0.04 | 11 | Ø140 Ø168 | 3.6m |

ZWBJ-20 | 20 | 0.04 | 11 | Ø150 Ø178 | 4.2m |

ZWBJ-30 | 30 | 0.04 | 15 | Ø140 Ø168 | 4.8m |

ZWBJ-50 | 50 | 0.04 | 18.5,22 | Ø180 Ø219 | 4.8m above |

ZWBJ-60 | 60 | 0.04 | 30 | Ø200 Ø245 | 4.8m above |

Kiln car and drying car are vehicles in the brick making industry that carry bricks and transport them into sintering and drying facilities. In the past, the bricks were layered and stacked in layers and stacks according to a certain structural form. When the kiln car is used in conjunction with the automatic blanking equipment, it needs to accurately reach the designated position, and during the blanking process, it needs to reciprocate and move in multiple positions according to the blanking method. At present, there are two driving methods for the kiln car to move on the track. The first is manual push, and the second is wire rope traction. Due to the use of hook connection in the way of wire rope traction, a stepping machine can only achieve one-way pulling, but cannot achieve two-way and precise movement. Manual cannot achieve accurate and fast positioning. As the size of the kiln car is getting bigger and bigger, and the method of stacking the blanks is more complicated, a kiln car may need to stack the blanks multiple times and in multiple positions. Therefore, the automation of the code blank urgently needs the cooperation of the stepping machine that can realize the linkage and precise movement with the system.