Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:10 unit

Supply Capability:10000 unit/month

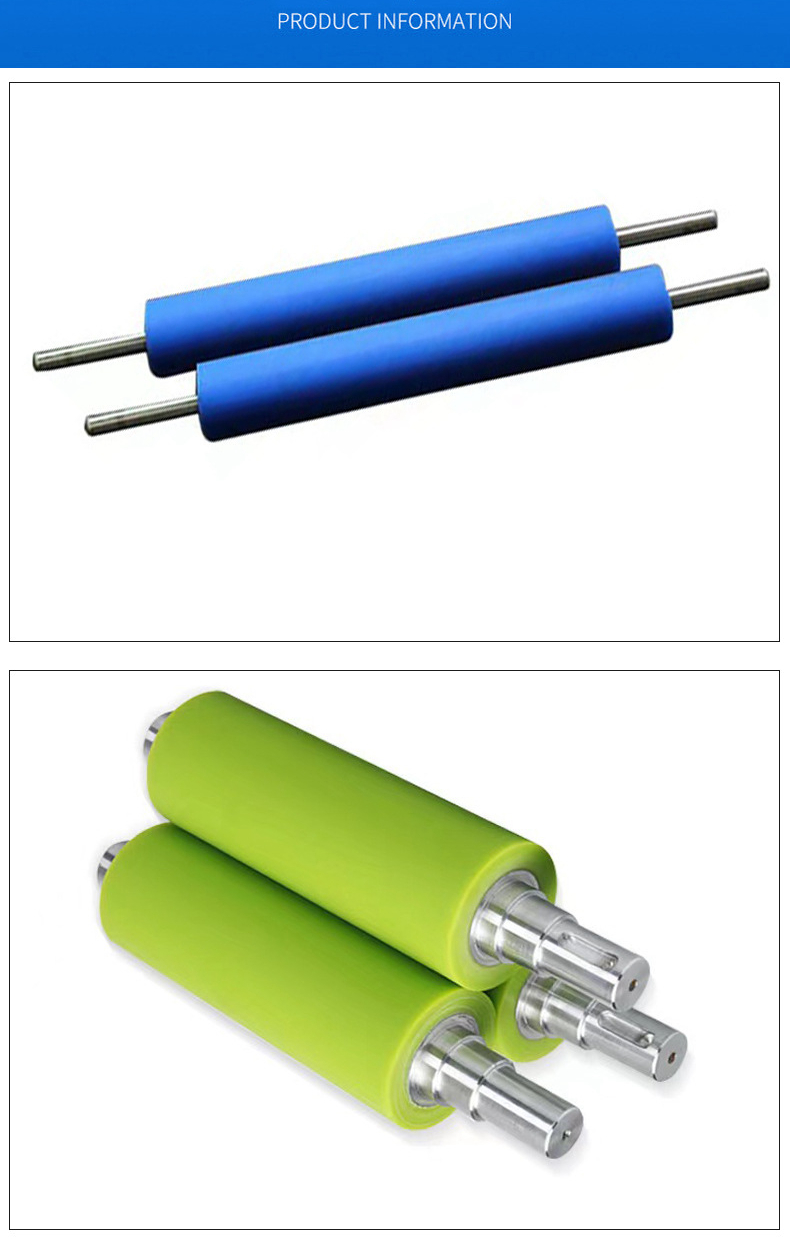

Rubber covered roller is a rubber or an elastic material covering the core made of metal or other materials.

Rubber covered rollers are used in wide applications.

Features of Rubber Roller

High coefficient of friction

Quickly returns to its original shape when the shape is distorted

Resistant to chemical substances and protects the roller core and shaft

Prevents damage caused by scratching and bumping

Compensates for small changes in machine precision

Details of Rubber Roller

Processing Service | Covering, Cutting, Moulding etc |

(Customerized) Model Number | Will be applied |

Diameter | depend on drawings |

Core material: | steel/Aluminum/ as required |

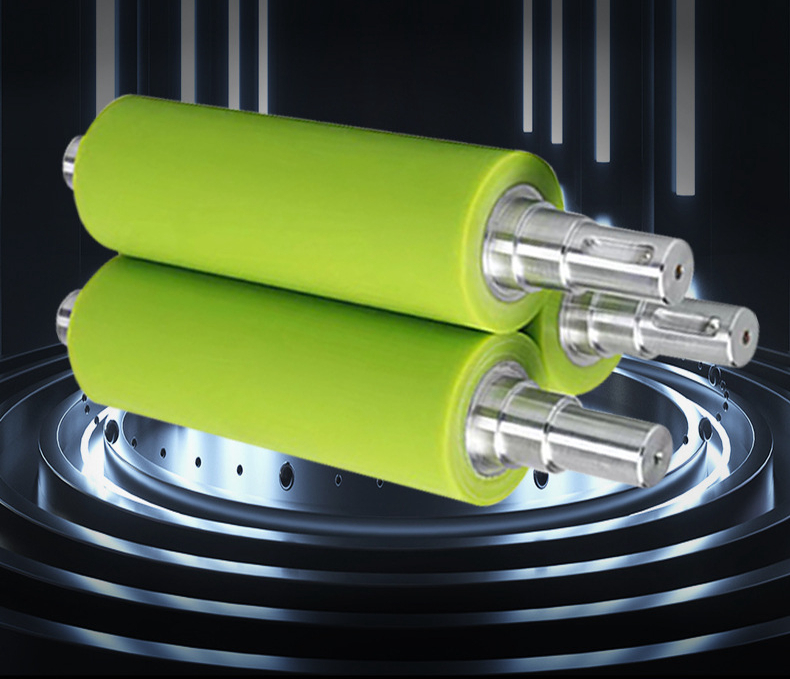

Rubber Material | EPDM, NBR, PU/as required |

Rubber thickness | depend on drawings |

hardness | As customer’s request |

Color | depend on drawings |

Core Components | Shaft |

Processing Scope | |

Max. length | 12000mm |

Max diameter | 2000mm |

Hardness scope | (ShoreA) 15°-100° |

We have many durometers, colors and compound alternatives to meet your requirements; or we can adjust an existing stock to specifically fit your rubber covered roller application.

Material | Hardness Shore A | Features | Applications |

Buna-Nitrile | 20-95 | Enhance toughness Resilience Oil resistance | Printing Steel Paper |

EPDM | 30-95 | Superior chemical resistance Release properties Ozone tolerance | Flexographic printing UV ink, Coating Laser engraving |

Natural Rubber | 25-99 | High elasticity High physical properties Cold resistant | Printing Industrial applications |

Silicone | 40-90 | High heat tolerance Good release characteristic | laminating coating |

Polyurethane | 25-95 | Abrasion Resistance Cut Resistance Higher bond strength | Copper Foil Aluminum Foil Iron and Steel |

Neoprene | 25-95 | Superior aging-resistant Oil resistant | Textile Belting |

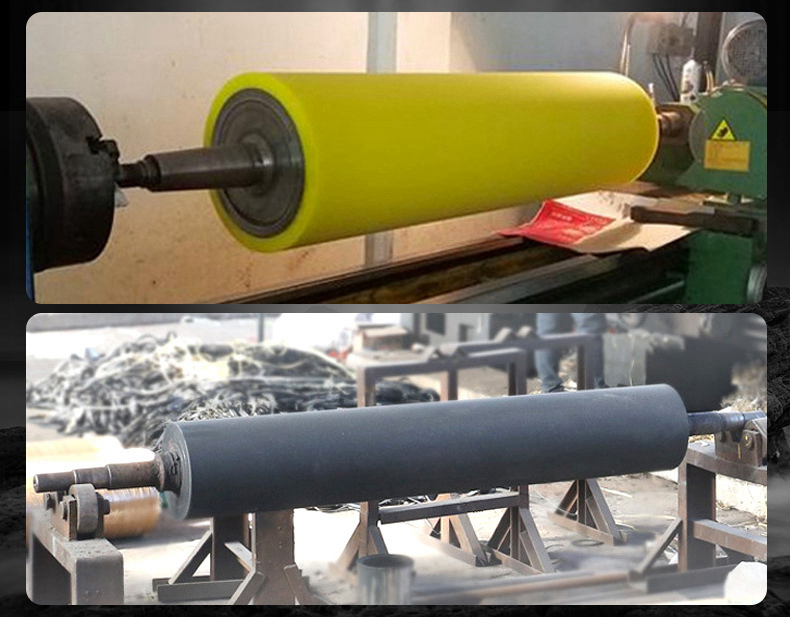

Processing Capacity

Annual Prodcution Capacity: 5 billion cm³

Maximum Processing Length: 12000mm

Maximum Processing Diameter: 2000mm

Hardness Shore A: 15°~100°