Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

GeneralInformation

GeneralInformation

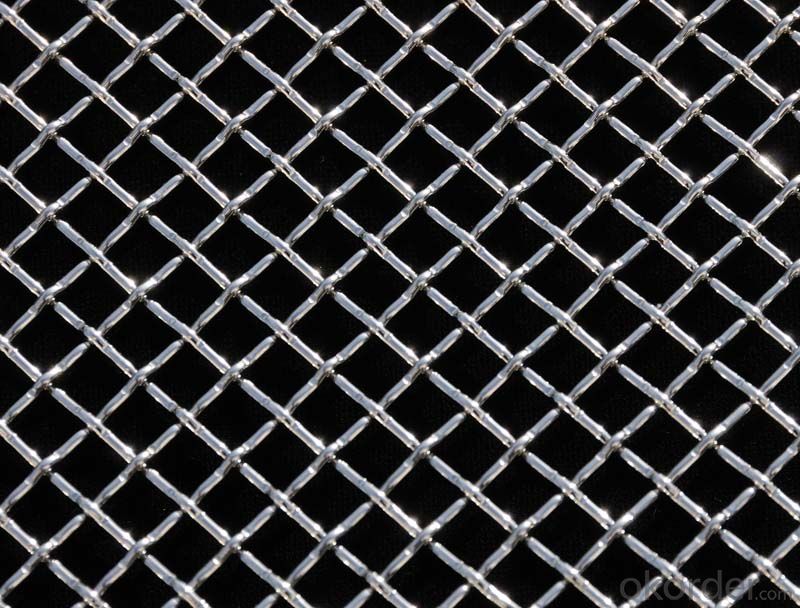

Type: blank/uncoated, galvanized*, stainless steel, aluminum,copper, brass, plastic-coated

• Width of the grid: 400 – 2.200 mm

• Length of the grid: 300 – 7.000mm, or in roll form up to 50

• Dimensional tolerances in lengthand width: -0 mm /+1 mesh width (customary)

• On request fixed measures withtolerances of +/-2 mm in length and width

Galvanized double intermediate crimp screens aremanufactured from previously galvanized wire. The zinc coating is ca. 7 µm.Galvanized double crimp screens therefore are only limitedly suitable foroutdoor use.

Product Range

Weight of double intermediate crimp screens – in kg/m² | ||||||||||

Mesh width [mm] | Wire diameter [mm] | Crimps* | ||||||||

1,6 | 1,8 | 2,0 | 2,5 | 3,0 | 3,4 | 4,0 | 5,0 | 5,8 | ||

8 x 8 | 3,5 |

|

|

|

|

|

|

|

| 3 |

10 x 10 | 3,0 | 4,2 | 4,5 |

|

|

|

|

|

| 3 |

12 x 12 |

|

| 3,8 |

|

|

|

|

|

| 3 |

15 x 15 |

|

| 3,1 | 4,7 | 6,7 |

|

|

|

| 3 |

20 x 20 |

|

| 2,4 | 3,7 |

|

|

|

|

| 5 |

20 x 20 |

|

|

|

| 5,0 | 6,8 | 9,5 |

|

| 3 |

25 x 25 |

|

|

| 3,1 | 4,3 |

|

|

|

| 5 |

25 x 25 |

|

|

|

|

| 5,5 | 7,7 |

|

| 3 |

30 x 30 |

|

|

| 2,7 |

|

|

|

|

| 7 |

30 x 30 |

|

|

|

| 3,8 | 4,6 |

|

|

| 5 |

30 x 30 |

|

|

|

|

|

| 6,0 | 10,7 |

| 3 |

35 x 35 |

|

|

|

| 2,9 | 4,1 | 5,2 |

|

| 5 |

40 x 40 |

|

|

| 2,4 |

|

|

|

|

| 9 |

40 x 40 |

|

|

|

| 2,8 |

|

|

|

| 7 |

40 x 40 |

|

|

|

|

| 3,5 | 4,7 |

|

| 5 |

40 x 40 |

|

|

|

|

|

|

| 7,3 | 10,2 | 3 |

50 x 50 |

|

|

|

| 2,3 |

|

|

|

| 9 |

50 x 50 |

|

|

|

|

| 2,9 | 3,8 |

|

| 7 |

50 x 50 |

|

|

|

|

|

|

| 5,8 | 8,1 | 5 |

60 x 60 |

|

|

|

|

|

| 3,3 |

|

| 7 |

60 x 60 |

|

|

|

|

|

|

| 5,3 | 6,9 | 5 |

75 x 75 |

|

|

|

|

|

|

| 4,4 | 5,9 | 7 |

100 x 100 |

|

|

|

|

|

|

| 3,5 | 4,5 | 9 |

Application Areas

Our doubleintermediate crimp screens are used in the following fields as:

Safety grids (e.g. car industry,mechanical engineering, building industry)

Filling elements for gates andfences in buildings and gardens

Booth construction

Plant breeding

Pigeon barriers

Noise protection

Lock crimp/Lock-Crimp Weave/Scalping Weave

Slotted screens (against flow)

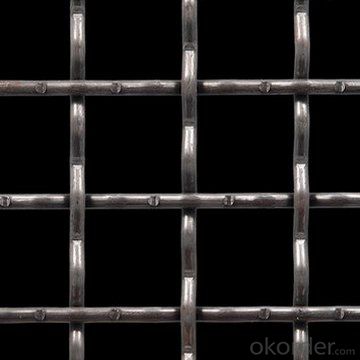

Flat top screens with aone-sided plane surface have their chain and weft wires in plane position atthe intersection points due to the single-sided crimp of the wire. This methodgenerates a grid with a plane, unbroken bottom side.

General Information

Type:blank/uncoated, galvanized*,stainless steel, aluminium, copper, brass.

• Width ofthe grid: up to 2.200 mm

• Length ofthe grid: up to 5.000 mm or in roll form up to 50 m

•Dimensional tolerances in length and width: -0 mm /+1 mesh width (customary)

• Onrequest fixed measures with tolerances of +/-2 mm in length and width

The nominal size of the flat top screen always specifiesthe mesh width (=inner width).

Application Areas

Weight of flat top screens with a one-sided plane surface – in kg/m² | |||||

Mesh width [mm] | Wire diameter [mm] | ||||

2,0 | 2,5 | 3,0 | 4,0 | 5,0 | |

8 x 8 | 5,2 |

|

|

|

|

10 x 10 | 4,3 |

|

|

|

|

12 x 12 | 3,7 |

| 7,7 |

| 18,9 |

13 x 13 |

| 5,2 |

|

|

|

15 x 15 | 3,0 | 4,7 |

|

|

|

16 x 16 |

|

| 6,1 | 11,0 |

|

20 x 20 | 2,3 | 3,5 | 5,0 |

|

|

25 x 25 |

|

| 4,1 | 7,3 |

|

30 x 30 |

| 2,7 | 3,5 | 6,2 |

|

40 x 40 |

|

| 2,7 | 4,5 | 7,5 |

50 x 50 |

|

| 2,4 | 3,6 | 5,8 |

60 x 60 |

|

|

|

| 4,9 |

75 x 75 |

|

|

|

| 4,0 |

Flat topscreens with a one-sided plane surface are used in all fields where constantmesh width and the advantage of a one-sided plane surface are required, e.g.shelves, cage bottoms, support grids for filter fabric, stackable bin walls,security and cover grids. Flat top screens are becoming more and more importantas creative element in the architectural sector (e.g. as cladding for walls andceilings.)

Hook Strips for Screen Sections | ||

|

| Standard Hook Strip, Type 21, for side tensioning |

|

|

|

| Standrad Hook Strip, Type 21, for end tensioning | |

|

|

|

| Double Fold Hook Strip, Type 30, for side tensioning | |

|

|

|

| Double Fold Hook Strip, Type 30, for end tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for side tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for end tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for side tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for end tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

Tensioning Bolts | ||

| Flat Tensioning Bar with tensioning bolts. Please indicate measurements a + b and length of bolt. | |