Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 pc

Supply Capability:1000 pc/month

CQB series fluorine plastic magnetic pump description

CQB series fluorine plastic magnetic pump, using magnetic coupling drive, without dynamic seal point, solving general shaft drive centrifugal pump seal outside run, drip problem. Flow components are using fluorine plastic and high purity of industrial ceramics, It has excellent corrosion resistance and seal ability, widely used in chemical, pharmaceutical, aluminum foil, acid, paint, and other non-ferrous metal industries and explosive, volatile, toxic transport, organic solvents and precious liquids.

Applicable temperature:-20C~100°C

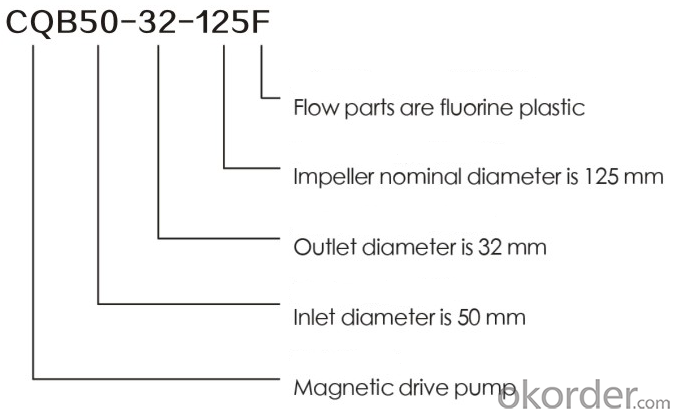

2. Model sense

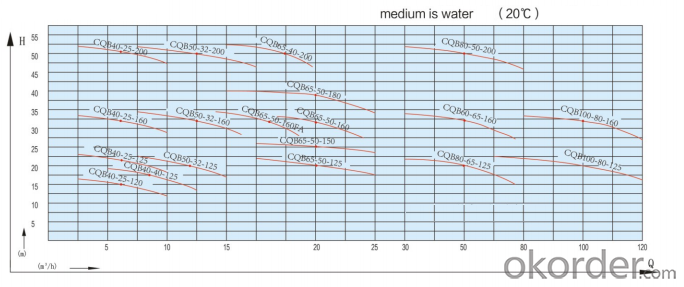

3. Performance curve diagram

Situation: The medium is water and n=2900r / min

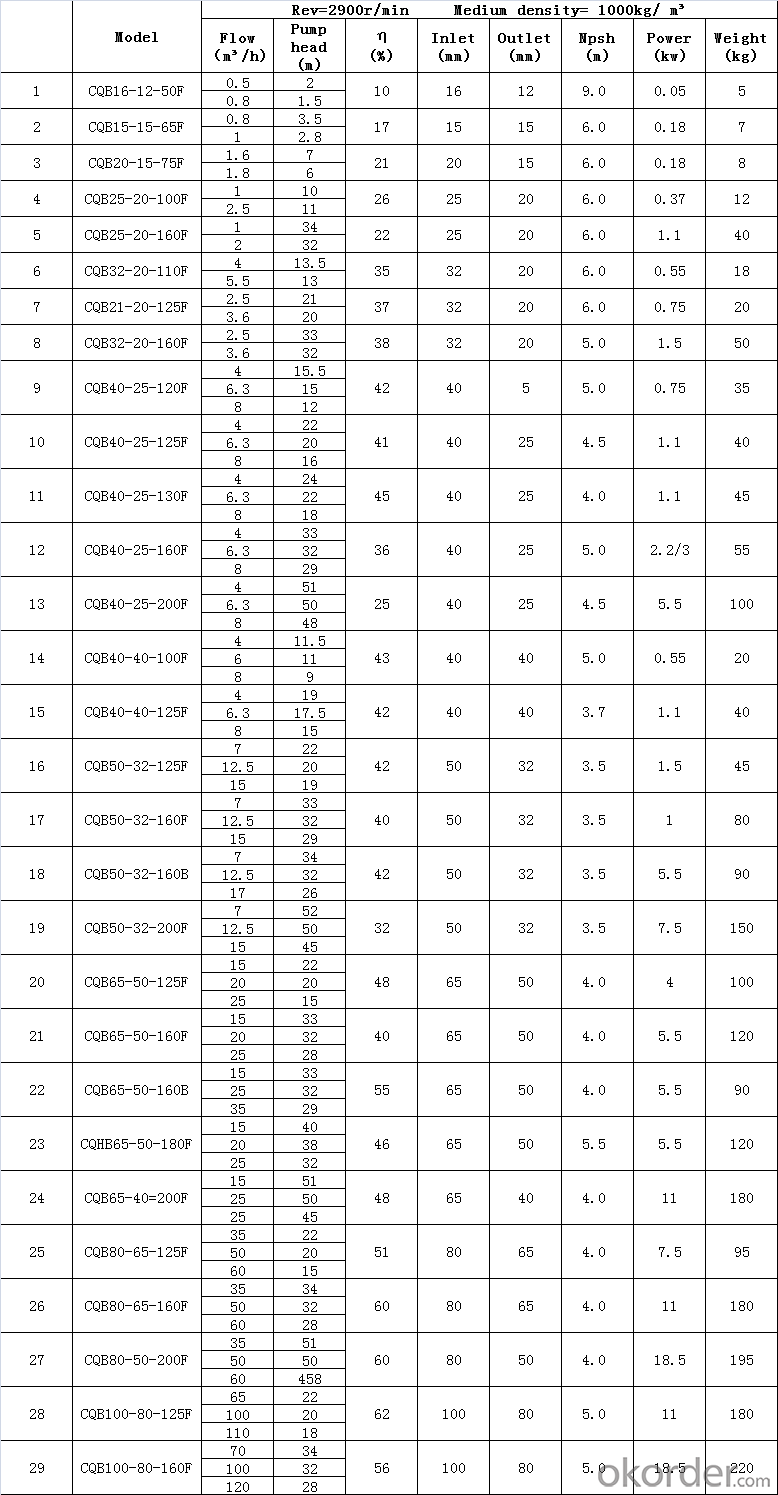

4.Model performance

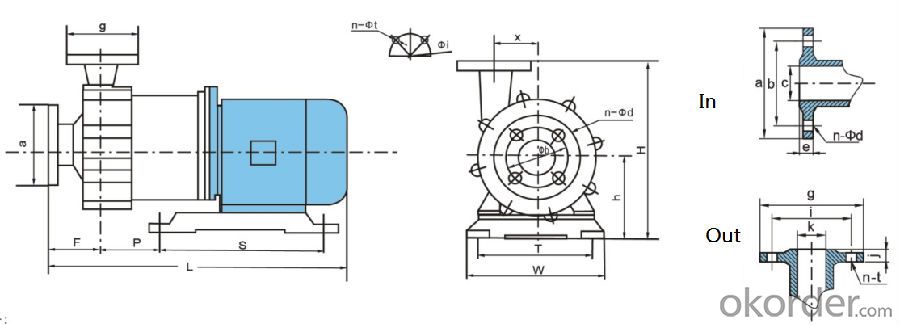

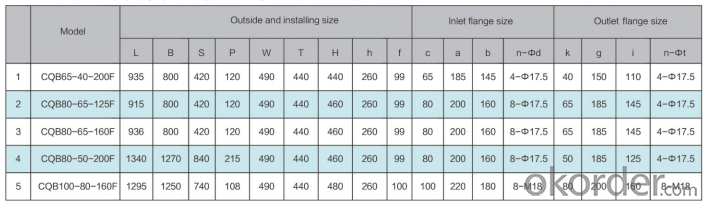

5. Install size / flange size

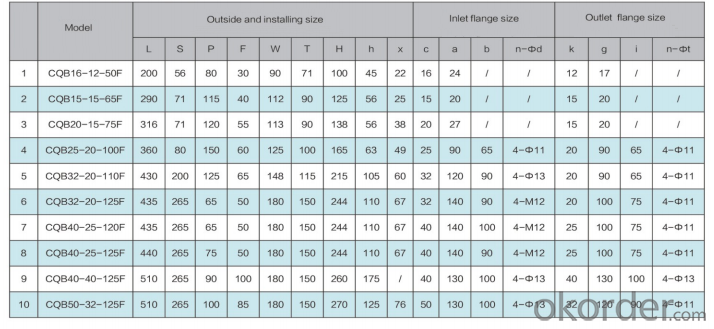

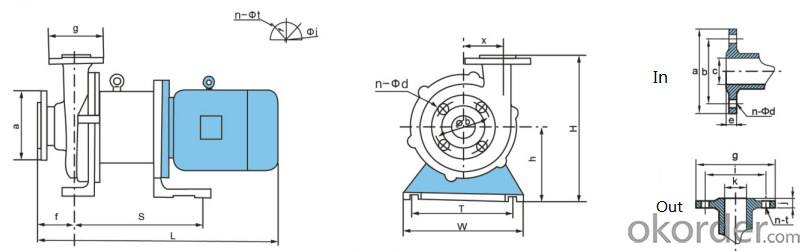

Type one:

schematic diagram

Data specification

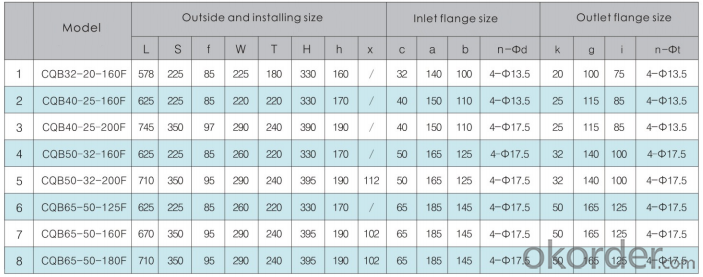

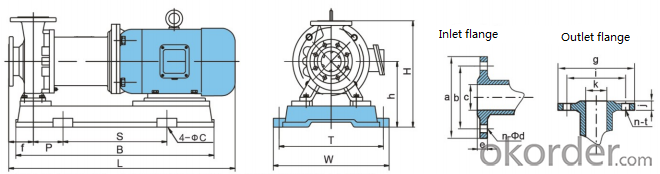

Type two

schematic diagram

Data specification

Type three

schematic diagram

Data specification

6. Installation and maintenance Notes

-. Make concrete foundation in accordance with the basic size and embedded anchor bolts.

- Check the pump and motor before installation, all parts should be in good condition, no debris inside the pumps.

- Install the unit on the basis of concrete, put pairs wedge cushion between the base plate and foundation, through high-speed cushion, find the right horizontal position on the pump.

- The inlet and outlet pipe line should have a supporting foot, can't use the pump to stand pipe line. The inlet& outlet diameter of the pipeline and the inlet& outlet diameter of the pump should be same.

- After installation, turn the coupling by your hand and check whether if any rubbing.

- Magnetic pumps not allow to extract the medium which containing particles.

- In order to prevent debris entering the pump, should be located in the entrance filter, filtering area should be greater than the pipe cross-sectional area of 3-4times

- High head pumps should be installed back valve on the outlet pipeline, in order to prevent the sudden stop caused by water hammer damage.

-Must ensure that the installation height of pump in line with the pump NPSH and consider the pipeline loss and temperature of the medium.

- When the medium temperature is too high, the cooling measures should be taken, in order to prevent the machine seal deformation, static ring cracking.