Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:10 m.t.

Supply Capability:100000 m.t./month

Product Description:

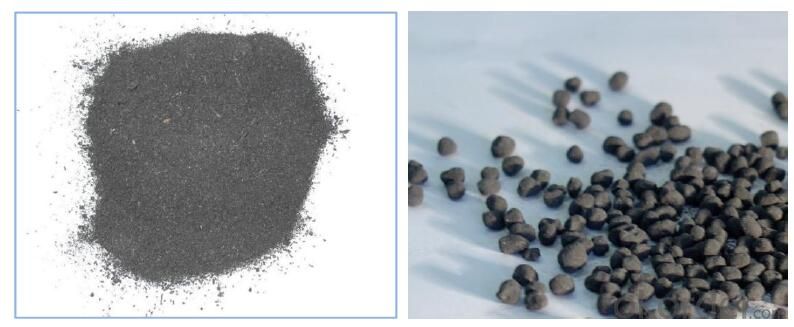

We offer a series of covering flux products including both fine-grained powders and hollow granulated fluxes, so it’s possible for customer to select a suitable material according to operational parameters of each specific application.

Generally for tundish application factors affecting product performance result to be steel grade, exposed steel surface to be covered, casting time, and sequence index.

Regarding ladle applications, critical factors are chiefly the amount and the characteristics of the refining slag.

Increasing demand of better quality steel and subsequent use of high performance basic tundish lining material boosted researching and developing of active basic tundish powders assuring high covering, insulating properties and low corrosion activity.

Moreover, effective NMI (non-metallic inclusions) absorption capability is provided by specific viscosity and surface tension of molten slag layer in direct contact with molten steel.

Plant experience in using these active basic tundish powders gave improved steel cleanness.

Insulating covering fluxes for tundish and ladle

We offer two types of insulating covering fluxes :

Rice ash, with high levels of thermal insulation

Fly ash mixtures, with high levels of thermal insulation and protection against re-oxidation

Insulating MgO-based covering fluxes

Spray-dried covering powders based on magnesite and with very low silica content, with good thermal insulation properties, protection against re-oxidation and low refractory erosion.

Active basic powders

We offer two types of active basic powders:

Active basic powders for tundish (CaO-based) in fine-grain powders and granulated form to maximize absorption of NMI.

Calcium aluminate based material is well known to give metallurgical active slags able to prevent sulphur pick up to the steel. It offers the potential for oxide pick-up and protection against re-oxidation. It is a material obtained by complete melting in high-capacity furnaces of bauxite and limestone. Because such materials have poor insulating properties, it is necessary to add an additional insulating compound on top.

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.