Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:100 pc

Supply Capability:2000000 pc/month

What is Corundum Brick?

l Corundum Bricks are high alumina refractory bricks are made for extreme demands. The alumina content in Corundum Bricks can be traced to the use of synthetic corundum of high purity, such as white fused alumina or tabular alumina. Additional ingredients are special refractory clays, reactive alumina and very pure modifications of silica.

l Corundum Bricks are fired at high temperatures to form a matrix with mullite, mullite-corundum or corundum that has excellent volume stability.

l The service temperature for Corundum Bricks goes up to 1800°C.

What are the applications of Corundum Brick?

Corundum Bricks can be used nearly all fields of industrial application where extreme high temperature and increased resistance against aggressive slags and atmospheres. Such properties or features of Corundum Bricks are necessary especially in the chemical industry and for the production of carbon black. The addition of chromium oxide, zirconium oxide and phosphates lends the bricks excellent structural flexibility, which is required for ash melting furnaces and gas reactors in incinerators.

Image of Corundum Brick

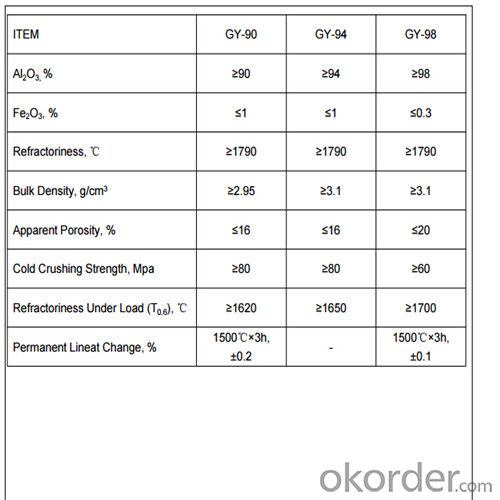

Technical Data of Corundum Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.