Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:10 set

Supply Capability:100 set/month

| Packaging Detail: | wooden case |

| Delivery Detail: | 10 days |

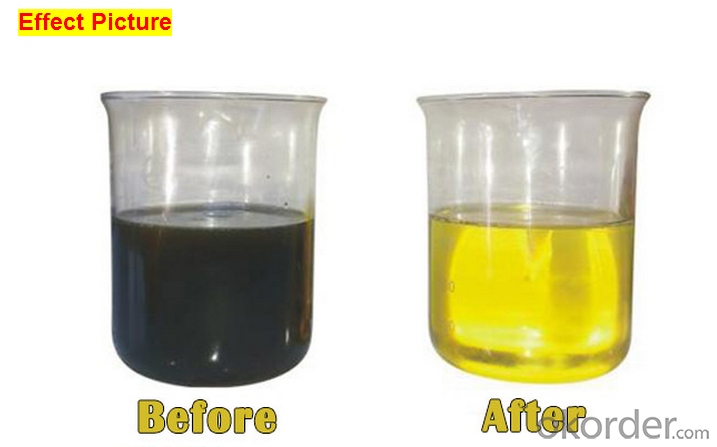

TYA series cooling and lubricating oil regeneration machine

1.Eliminates residue on parts

2. improve oil performance, low cost

TYA series cooling and lubricating oil regeneration machine

oil purifier, oil filtration, oil purification, oil filter,

oil treatment, oil saving, oil recycling, oil processing,

oil filtering, energy saving, oil regeneration, oil processor,

oil filter, oil process, oil purify, oil regenerating,

oil restoration, waste oil disposal, oil reclaimed, oil

reclaiming, waste oil management, oil regenerate, oil

reconditioned, oil reconstituted, oil restituting

TYA Water Oil Separator

#1 More separation volume and more coalescing media combined

with lower separation velocity at higher flow rate.

#2 The micro adjustable conical oil outlet weir allows visual

inspection of oil quality and dryness. The stainless steel handle

keeps your hands dry too.

#3 The TOP skimmer head works on the principle of a positive

buoyancy radial flow weir coupled with a floating or fixed combination

center sump and weir guide to effectively remove the oil or other light

immiscible liquids from the surface of the water.

Eliminates residue on parts

Reuse wash water

Reduce or eliminate disposal

Extend coolant life

Improve toll life

Improve part quality

Eliminates foul odors

Minimizes Dermititus

Reduce coolant purchases

Reduce disposal costs

Reduce compliance costs

Table1 TYA Oil Purifier Treated Guarantee Value

Item | Guarantee indexes |

Moisture content | ≤50 PPM |

Demulsification value | New oil≤15min,running oil≤30min |

Impurity size | ≤1 micron |

Gas content | ≤0.1% |

Clean degree | ≤4 Grade (NAS1638) |

Machine Technology

Dehydration (Degas) System

The duplex-stereo vacuum evaporation vessel can enlarge evaporation area

efficiently. The heater, being placed on the duplex-stereo vacuum evaporation vessel, becomes an evaporator. Thus the

evaporation area of duplex-stereo vacuum evaporation vessel is three

times more than that of

the common vacuum vessel. This innovation can dehydrate and degas

effectively and efficiently.

The optimal structure of the dehydration (degas) system enlarges the

surface area of oil exposed to the vacuum system and extends the

flowing distance of the oil in the vacuum system. Thus there has

sufficient time to remove the moisture and gas from the oil by vaporization.

•Filtering System

The filtering materials with variable apertures are made of specialized

glass fiber. The sizes of the filtering fiber and aperture dwindle

gradually in the different filtering stages. The impurities with different

particulate sizes are filtered step by step. The capability of removing

particulate matters and impurities is improved greatly by this method.

The filtering system has stable and perfect filtering fineness. The

filtering fineness has several grades, including 1, 2,3,4,5,6,10 µm etc.

Oil β≥1000 after filter.

The filtering system is equipped with reverse rinse and filth device.

It improves the effectiveness of filtering and extends the lifetime of

filter awfully.

• Electrical Apparatus controlling System

The main components of the electrical apparatus made by Siemens Company

ensure the safety of the controlling system. Having several protection

systems which will avoid oil ejection, overload and over voltage etc.

• Oil heating System

The unique heater structure heats the oil uniformly.

Oil Heater System assures less than 1.0 w/cm². During the heating

process, the deterioration of the oil caused by overheating is avoided.

The oil temperature can be adjusted between 0℃ to 100℃.The heater is

controlled manually or automatically. The heater will stop automatically

when the oil temperature reaches a certain degree.

Being installed with safety protection devices, the heating system is

secure and reliable. The heater will stop operation automatically when

the oil volume of inlet is too low to avoid the damages of the heater.

• Oil-level Controlling System

The oillevel floating ball and infrared liquid level automatic

controller system are installed in the vacuum vessel to control the

oil level so as to avoid the oil leaking in the operation.

The new innovation of eliminating froth can avoid the oil ejecting

and gushing during the process

• High quality components

The main component parts of our products such as vacuum pump, oil

pump and electric apparatus are from SIEMENS, ABB, SCHNEIDER and

AMICO etc. It ensures our products high quality and reliability

• Structure and appearance of Oil purifier

Our products adopt ship-shape chassis-mount structure to ensure oil leak proof and protect the environment

from pollution.

The whole equipment is characterized by small size, light weight and

convenient to move around.

Various sizes and configurations(alloy shield) available

Available in mobile or stationary options

Automatic vacuum oil purifier or anti-explosion vacuum oil purifier is both available according to customers’ needs.

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.