Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:1000 set/month

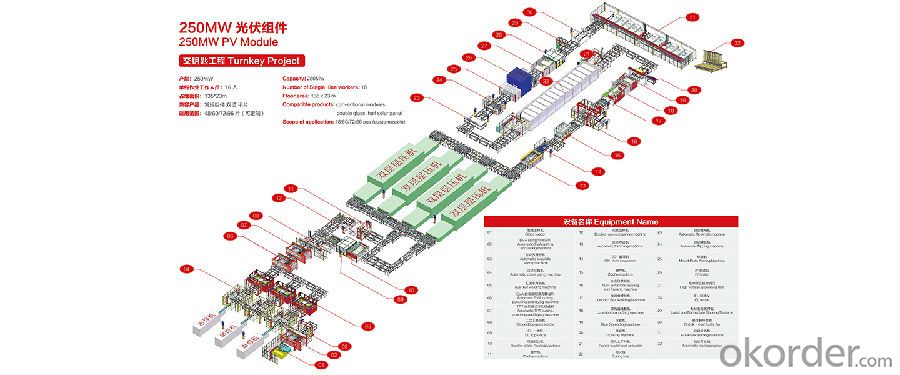

Photovoltaic solar panel production line CNBM

Product description

The photovoltaic solar panel production line is specially used to produce photovoltaic solar panels, which can produce multi-specification solar panels.Our company has many years of construction experience in overseas engineering projects.The photovoltaic production line has less investment, short construction time, and quick return on costs.We have a professional design team and can provide design solutions for free.

Device name

| 1 | Glazing machine |

| 2 | EVA EVA automatic cutting and laying machine |

| 3 | Automatic template releasing machine |

| 4 | Automatic pendulum string machine |

| 5 | Bus welding machine |

| 6 | EVA EVA automatic cutting and punching laying machine |

| 7 | TPT TPT automatic cutting and punching laying machine |

| 8 | Double glazing machine |

| 9 | EL EL all-in-one |

| 10 | Double glass automatic edge sealing machine |

| 11 | Cache machine |

| 12 | Double glass repair machine |

| 13 | Automatic trimming machine |

| 14 | 90° 90 ° turnover |

| 15 | Cache machine |

| 16 | Automatic glue group frame machine |

| 17 | Junction box welding machine |

| 18 | Junction box filler |

| 19 | Glue spreading machine |

| 20 | Potting machine |

| 21 | Curing line feeder and feeder |

| 22 | Curing line |

| 23 | Automatic Angle reducer |

| 24 | Automatic board Turner |

| 25 | The machine |

| 26 | IV IV tester |

| 27 | Insulation and voltage grounding test |

| 28 | EL EL tester |

| 29 | Automatic signage machine |

| 30 | The final inspection |

| 31 | Automatic file divider |

| 32 | Automatic baling machine |

The above equipment can be customized according to customer requirements, reducing or adding equipment.

The main parameters of some devices will be updated below.

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to produce.

2.Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be made out with 40 working days.If you need machines in hurry, we can make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7.How to visit your factory?

By high speed train from Shanghai to Wuxi (Wuxi station), an hour.

8.What's the warranty period?

12 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the Buyer’s Installation site.

9.Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide door-to-door service.