Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

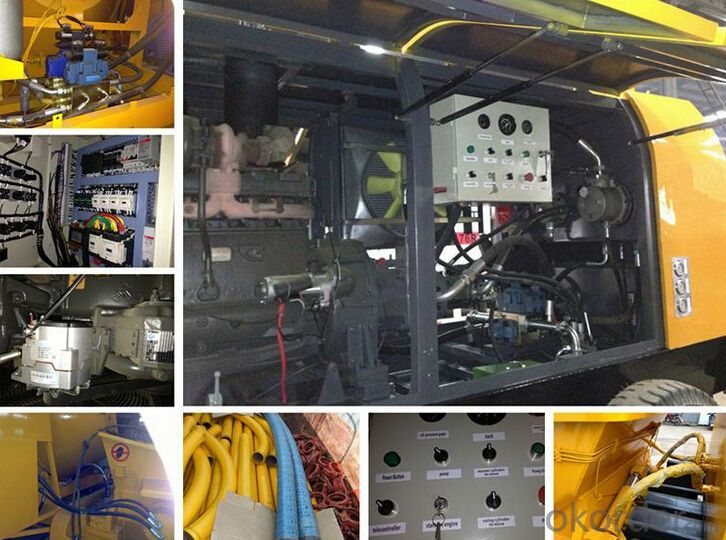

1.Power system

Hydraulic oil pump: Germany Rexroth or Japan Kawasaki are adjusted.

Diesel power: Germany Deutz, Weichai, Schneider, Japan Siemens, Mitsubishi are adjusted.

The main power could be adjusted by the user

2.Electronic control system

Japan Mitsubishi Programmable Logic Controller (PLC) electronic control system.

Main electric elements are imported original Schneider, Siemens, OMRON, LG etc.

The control mode: manual operation and wireless remote control

Humanity and intelligent electronic control system optimizes the person-machine interface.8-digital pumping time accumulation timer provides exact data for the user, Automatic anti-pump function and optimized program design. Automatic trouble monitoring function.

3.Hydraulic system

The unique open hydraulic system and hydraulic cushion technology contribute to the smaller exchange impact and less heat of the system.

Meanwhile, with the famous brand of main pump and hydraulic valve, the safety and reliability of the concrete pump are guaranteed.

The hydraulic pipeline selects the high performance seamless steel pipes and all pipe joints and high-pressure hoses are of the famous brands.

A number of high pressure accumulators and their excellent cushion performance reduce the requirement of S pipe vale for the concrete.

The concrete is delivered freely.

4.Pumping system

Pumping displacement variable adjustment: Change the pumping displacement according to the construction to meet the requirement of the condition.

Reducing design of the hopper could release the reducing pressure of the concrete into the delivery pipe maximally, and prolong the service life of the S pipe outlet.

5.Lubrication System

The patented central automatic lubrication system comes with a piston grease-pump, features high pressure and reliability, which can realize automatic lubrication of piston. The filters at the outlet and the inlet of oil ports as double protections guarantee the system reliability.

6.Cooling System

Compulsory air-cooled heat exchanger keeps the temperature of the hydraulic oil below 60 degree, that ensures the whole hydraulic system works at normal status.

Main parameters:

Item | HBTS40—12—55 |

Max Theoretical Concrete Output (Low/High pressure) (m³/h) | 40 |

Max Concrete outlet Pressure (Low/High pressure) (Mpa) | 12 |

Concrete slump (mm) | 120—230 |

Aggregate Size (mm) | gravel≤40 |

Powder (KW) | Electric motor 55 |

Speed (r/min) | 1480 |

Conveying Cylinder Diameter (mm) | Ø 100/1600 |

Concrete Cylinder Diameter (mm) | Ø 180/1600 |

High-Low Pressure Switch | Yes |

Fuel Tank Capacity (L) | 400 |

Hopper Capacity (m³) | 0.52 |

Filling Height (mm) | 1400 |

Maximum Theoretical Conveying Distance (vertical Height/Horizontal Distance) (m) | 150/850 |

Pipe Cleaning Mode | Washing |

Overall Dimension (mm) | 5020*2010*2200 |

Total Weight (kg) | 4308

|