Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:6 unit/month

Application Scope

Quenching heat treatment of metal workpiece.

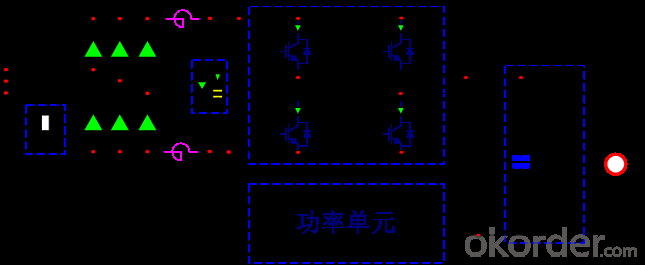

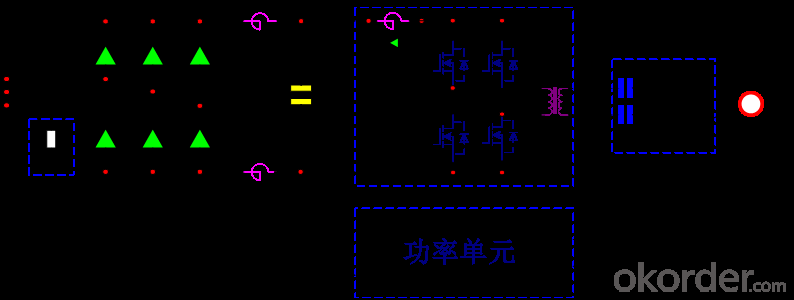

Function Structure

Complete set of quenching equipment is mainly composed of quenching machine tool, quenching power supply (medium frequency power supply, high frequency power supply, super-audio frequency power supply) and cooling equipment. The quenching machine tool is composed of machine tool bed, upper and lower clamping mechanism, clamping and rotating mechanism, cooling system, quenching liquid circulation system and electric control system. Customer can select quenching machine tool as per quenching technics. For special workpiece or technics, the quenching machine tool can be designed and manufactured according to heating technics requirement.

Quenching power supply generally selects parallel induction heating power supply. In order to stabilize quenching frequency to adapt multiple workpiece specifications, tank circuit of quenching power supply need to select quenching transformer.

Technical Features

Ø Perfect structure design

1.Integration design of switchgear rectifying cabinet and inverter output cabinet, with compact structure and small size.

2.The power supply selects DC chopper mode to ensure the grid side power coefficient≥0.92 and a relative lower harmonic content.

3.High standard electromagnetism compatibility design, electromagnetism radiation meets national standard. Closed cabinet design, meeting rigor environmental requirements on site.

4.The shape of quenching inductor is decided by workpiece and quenching technics, and the inductor is well-made.

Ø control system

1. PLC program control or CNC numerical control is optional.

2. AC full digital servo control, numerical control system adopts every advanced control circuits to reduce position tracking error to minimum, and compensate nonlinear error of static/kinetic friction of mechanism system automatically.

3. Quenching machine tool and power supply has perfect protection function with reliable working and low failure rate.

* Can be customized according to user’s requirement.

* equipment selection

Ø penetration heating:A kind of heating method that heat treatment layer is less than current thermal penetration depth, and with suitable specific power density.

Workpiece surface superheat is small, with thin thermal transition layer and high heating efficiency (quenching efficiency is 30~40%)

Ø power:

power density (specific power):The ratio of the power acquired by the workpiece to the heating surface.

| kW/cm2 | simultaneity heating quenching | continuous heating quenching | ||

| Quenching method | specific power scope | commonly used specific power | specific power scope | commonly used specific power |

| M.F. quenching | 0.5~2.0 | 0.8~1.5 | 1.0~4.0 | 2~3.5 |

| H.F. quenching | 0.5~3.5 | 0.8~2.0 | 1.0~4.0 | 2~3.5 |

For workpiece with complicated shape (gear, keyway, eyelet), select lower limit.

For inner hole, flat surface, simple shape compact structure shaft and big workpiece, select upper limit.

Ø power:

For workpiece with complicated shape (gear, keyway, eyelet), the frequency should be lower.

Ø power distribution:

:(simultaneity factor)0.8~0.9