Loading Port:Lianyungang

Payment Terms:TT or LC

Min Order Qty:100 m³

Supply Capability:5000 m³/month

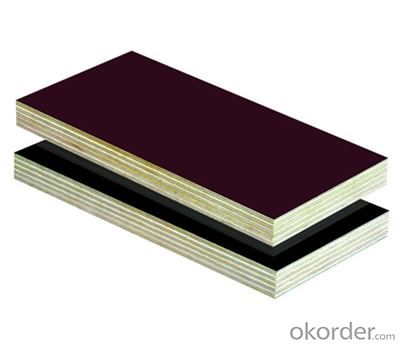

Specifications of Combi Core Black Film Faced Plywood

1.Usage:Decoration,Furniture,Construction.

2.Package:Inter packing:0.2mm plastic bag. Outer packing:Pallets are coverd with plywood or carton

3.Min order 1*20FCL or 23 cubic meter

4.Payment terms:L/C at sight,T/T 30% as deposit ,D/P.

5.Supply ability:6000 Cubic meter/month or 8000 pcs/day.

6.Main marke:Indonesia Malaysia India,Thariland,Middle East,Europe,Africa.

Description

| Marine plywood/Film Faced Plywood | ||

| Film | Brown film, Black film | |

| Core | Poplar, hardwood, pine and others | |

| Glue | WBP,Melamine,MR | |

| Size(mm) | 1220*2440, 1250*2500, or requested by customers | |

| Thickness(mm) | 6-27mm | |

| Density | >550-650g/CBM | |

| Moisture | 8-12% | |

| Modulus of Elasticity | >6000Mpa | |

| Modulus of rupture | >30Mpa | |

| Quantity | 20GP | 8 pallets/21M3 |

| 40GP | 16 pallets/42M3 | |

| 40HC | 18 Pallets/53M3 | |

| Min Order | 1*20 ft container | |

| Payment | T/T or L/C at sight | |

| Delivery time | Within 2 weeks after receiving deposit or Original L/C at sight | |

| Addition | Sample available | |

| film faced plywood pictures | ||

Features:

1. No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2. Good performance and more turnover use time.

3. It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4. Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5. This can moderate and contact 30% time for a project.

6. Corrosion resistant and ir will nor pollute the surface of concrete.

7. It is good to keep performance warm,ia favorable to make constrution in winter.8. Products can be made into warping plywood

9. It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different types.

FAQ:

Q:What are Advantage of Combi Core Black Film Faced Plywood?

A:As below:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type