Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:20 m.t.

Supply Capability:60000 m.t./month

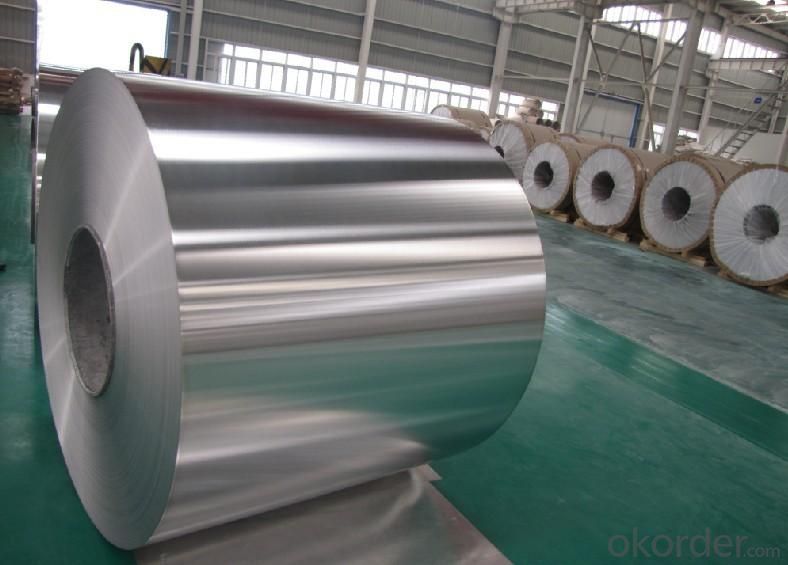

Color Coated Aluminum Coil Aluminum Alloy

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Description

Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.1mm to 1.2mm |

Width | Standard width:1240mm, 1270MM |

Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia:1200mm |

Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

outer diameter: 1200mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

Protective film | As per customer’s request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

Weight | As per customer’s request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

4. FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.