Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

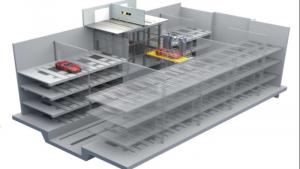

The introduction of coldrollforming section mill

The rolling plate in certainwidth is unfolded and leveled. Then, they are sent in to the forming machine.The steel plate is bent to be the needed form in the cold conditions by usingthe roller.

According to the differentproducts, the cold forming steel mills are divided into square pipe mill, steelsheet pile mill, and other kinds of mills.

Square pipe mill mainly producesthe square and rectangular pipes, all kinds of which in the range of roller productionspecifications can be achieved by using direct forming tectonics and theassisted high frequency welding machine.

Steel sheet pile mill mainlyproduces the steel sheet pile by adopting piecewise arc flexible formingtechnology. Steel sheet pipe mill in our company has reached the top level allaround the word.

Other models can produce U-steel,Hat shape steel, carriage U-steel, C-purlin and other steels by changing the roller