Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:1 set/month

Tons of Potassium Sulfate Project

General

CNBM is a high-tech enterprises international chemical engineering company, who is pioneering in chemical engineering technologies, and playing a leading role in new technology development, with capability of project consulting, design, procurement, construction management and production guidance. CNBM provide services of chemical engineering and technology, with offering a scope of supply ranging from process design till the supply of completely integrated plants. CNBM master a technology of Potassium Sulfate production line, Calcium Chloride production line,sulfuric acid production line other fertilizers.We have cooperated with many international companies on projects,located Indonesia,Philippines,India,Jordan,Egypt.etc.

Process Description

It is well-known as there are two kind of popular methods to be used to produce Potassium Sulphate Product, one is Double decomposition method, the reaction is not good, the product quality should be improved. Another method is the Mannheim furnace process, it is used widely. But there are some difficulties occurred during the production. CNBM had made the necessary and important improvement and perfection on its production equipment and production process of Mannheim furnace, to form a unique and perfect Potassium Sulphate production technology now. Our improved process had been successfully applied in Philippines, Indonesia and Egypt, to be approved that our process and technology is excellent, gets the Customer’s credit, trust and satisfaction. Of course, CNBM has been dedicating himself into building the best quality Potassium Sulphate Plant, to produce best quality final product.

The production process is showed as below:

Using KCl (MOP, Potassium Chloride) reacts with Sulfuric Acid to produce K2SO4 (SOP, Potassium Sulphate) and HCl (Hydrochloric Acid) as a by-product, the reaction formula is showed as below::

2 KCl + H2SO4 → K2SO4 + 2 HCl

The reaction of Sulfuric Acid with Potassium Chloride takes places in two stages:

a. KCl + H2SO4 → KHSO4 + HCl

b. KCl + KHSO4 → K2SO4 + HCl

The first reaction step is exothermic and proceeds at relatively low temperature. The second is endothermic and must be carried out at higher temperature. To minimize the Chloride content of the product, a small excess of Sulfuric Acid is used, which is later neutralized with Calcium Carbonate, depending on the purity requirements for the product.

The reaction is usually carried out in furnace which special designed by our company.

The furnace has a closed dish-shaped chamber, with diameter up to 6 m, heated externally by oil or gas burner. Potassium Chloride and Sulfuric Acid are fed into the chamber in the required ratio at an overhead central point. The mixture reacts with evolution of heat and it’s mixed by a slowly moving agitator fitted with central axle, the reacted material is ejected to next equipment from both side of furnace. Potassium Sulfate leaves the reaction chamber at this point and be neutralized and cooled. Hydrogen Chloride gas formed is absorbed in water to form Hydrochloric Acid.

Advantages of our Potassium Sulphate Plant :

Our company has developed the Potassium Sulphate (SOP) production line on equipment and process. There are some prominent advantages as followings:

1) We developed the 1st set of HCl waste gas recovery facility at the furnace gate in China. The spilled HCl gas when open the furnace gate for checkup, will be sucked out and absorbed by absorbing tower, which recovery the wasted HCl as well as eliminate the indoor pollution and meeting the indoor environmental protection requirement.

2) We has researched and developed the SOP production equipments for a long period of time. Especially the core equipment, furnace has very high thermal efficiency and productivity, also have long service life for equipment and furnace.

3) We successfully apply the DCS to the whole production line .The PID module of DCS with comprehensive function which easy to implement tracking step, switching, limit, etc to ensure more accurate and convenient for system control.And can be compatible with the equipment control system, easier to control the whole production line, adjusting and monitoring.

4) We developed and owned the core technology, to provide the project in a turnkey model, included basic and detailed engineering, supply of equipment and material, installation, commissioning, training, operation and long-term after-sale services as the whole engineering package. CNBM will train the production, management and maintenance staff for the client, and excellent managerial scheme and mature operation technology, which can help the client to solve the production and equipment problems from all perspectives. As a result, the client can enjoy long-cycle, high efficiency and benefits of production.

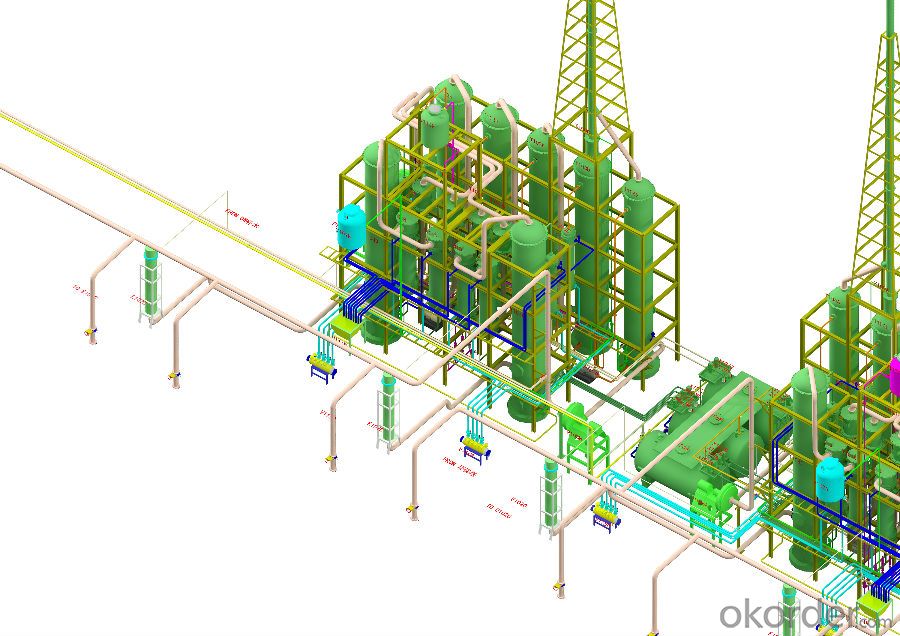

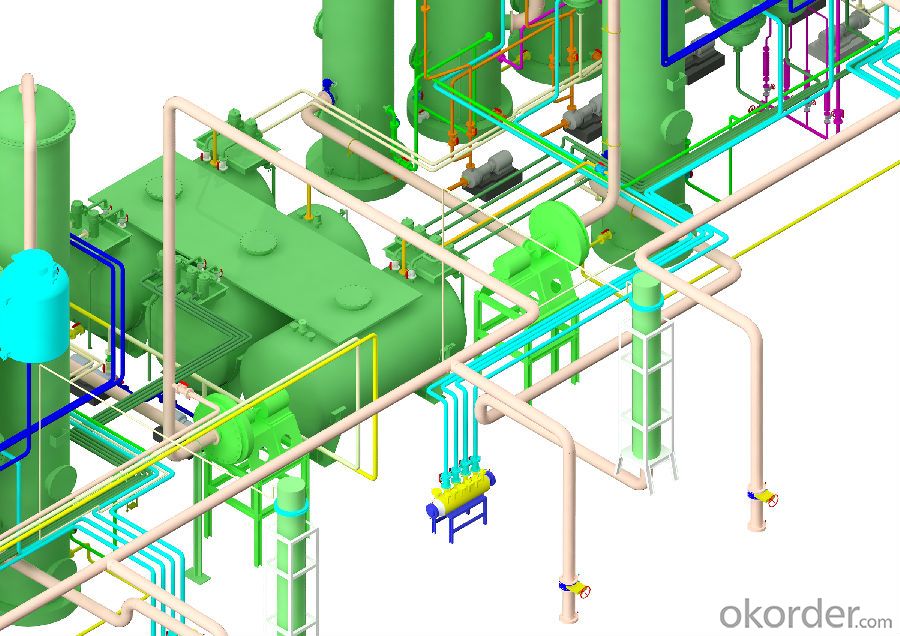

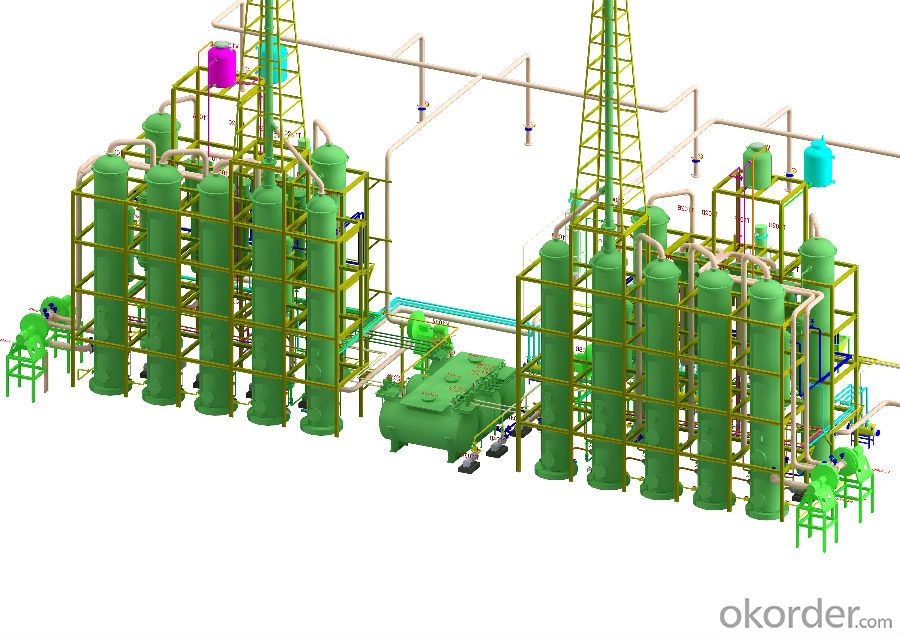

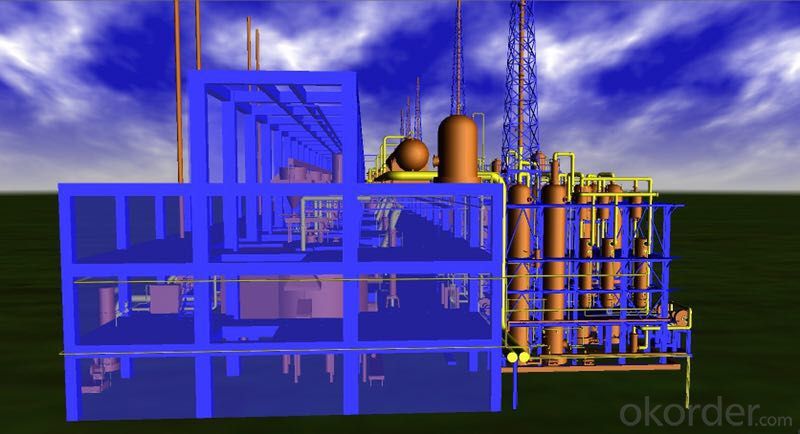

5) We made design using 3D software, it can shows a actual plant in different view, and check the rationality of equipment layout, pipeline and installation height of equipment and basis, etc. To avoid some errors made on site. This software have powerful drawings generated function which can enhance the design quality and make the final design efficiency. It can generate the construction drawing and material sheet directly by the software which can make the date more accurate.It can achieve visual design which instead of the traditional 2 D design .It also benefit to do the design optimization and adjustment of the arrangement according to the customer requirements and characteristics in a timely manner.

6) We always were dedicating in researching of furnace, not manufacturer of equipment, that means all of equipments used in our plant should be selected from the best supplier through our strict supplier selection system which ensure the equipment we provided are premium in quality, and followed our special design to produce and with our cooperation manners. For the standard equipment,we keep chose the famous brand in China.

For the core part,we chose the international famous brand to keep the lifetime of the plant .Such as we use the main motor with ABB brand instead of Chinese brand.

7) We have experience of built plant in different regions and countries, it means that we can make design based on clients required standards, product quality and environmental emission. And also capabilities on system integration and English document provision.

8) We have much experience on international logistics with professional logistic team, rich experience on container transportation and bulk transport.Also have strong ability to integrate the export and import documents. Such as customs clearance documents, C/O, and embassy certification documents .etc.

9) CNBM has developed and owned the core technology, can also train the production, management and maintenance staff for the client, and excellent managerial scheme and mature operation technology, which can help the client to solve the production and equipment problems from all perspectives. As a result, the client can enjoy long-cycle, high efficiency and benefits of production, which avoids the bothers to the clients.

3D drawings of productions: