Loading Port:Qingdao

Payment Terms:TT or LC

Min Order Qty:1 m²

Supply Capability:800 m²/month

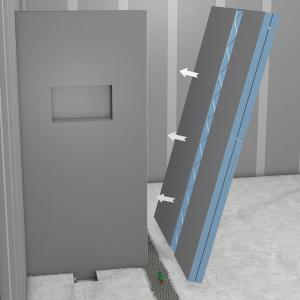

1.Introduction

Industrial、equipment rock wool board is designed to meet the needs of industry, equipment insulation rock wool board as Non-combustible grade A mineral wool products. It has good stability, durability and excellent noise reduction capabilities. The product is divided into sub-standard and hydrophobic. Aluminum foil or glass fiber cloth can be posted in the surface of the product.

specification model: |

Product code | TSI60 | TSI80 | TSI100 | TSI120 | TSI140 |

Nominal density (kg/m3) | 60 | 80 | 100 | 120 | 140 |

Length * width(mm) | 30~200 | ||||

Thickness(mm) | 1200x600 | ||||

Technical parameters: |

Product performance | unit | TSI60 | TSI80 | TSI100 | TSI120 | TSI140 | 标 准 |

thermal conductibility 50℃ | W/(m•K) | ≤0.040 | ≤0.038 | ≤0.038 | ≤0.038 | ≤0.038 | GB/T10295 |

thermal conductibility 100℃ | W/(m•K) | ≤0.046 | ≤0.045 | ≤0.045 | ≤0.045 | ≤0.045 | |

thermal conductibility 200℃ | W/(m•K) | ≤0.077 | ≤0.071 | ≤0.067 | ≤0.064 | ≤0.062 | |

thermal conductibility 300℃ | W/(m•K) | ≤0.120 | ≤0.099 | ≤0.095 | ≤0.090 | ≤0.085 | |

reshrinking temp | ℃ | 400 | 600 | 650 | 650 | 650 | GB/T11835 |

Moisture Absorption* | % | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | GB/T10299 |

water repellence* | % | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | GB/T5480 |

max service temperature | ℃ | 450 | 650 | 750 | 750 | 750 | ASTM C411 |

Chlorideion content** | mg/kg | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ASTM C871 |

linear shrinkage | % | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ASTM C356 |

File performance | -- | Non-combustible grade A | GB/T8624 | ||||

organic density | % | 2.0 | GB/T11835 | ||||

Melting point | ℃ | >1000 | |||||

The above figures are only for reference. With the development of the production facility and technology, we reserve the right to improve our product performance.**refers to the product of low chlorine.

2. CMAX ROCK WOOL BLANKET & BOARD STANDARD SIZE

PRODUCT | BLANKET | BOARD |

Density(Kg/m3) | 60-100 | 40-200 |

Thickness(mm) | 30-150 | 30-100 |

Size:L*W(mm) | 1200*3000-6000 | 600*1200 |

3.Typical applications:

It can be mainly used in industrial equipment, boiler industry, large diameter pipeline, and petrochemical.

4.Packaging and storage:

The product is packed in Polyethylene heat shrinkable film, which is very efficient to operate, transport and storage. For storage, a dry and ventilation warehouse is the best choice, of course, covered by water proof cover is another good way.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 40 working days can be served.