Loading Port:Lianyungang

Payment Terms:TT OR LC

Min Order Qty:0 SET

Supply Capability:10 SET/month

Product Advantage:

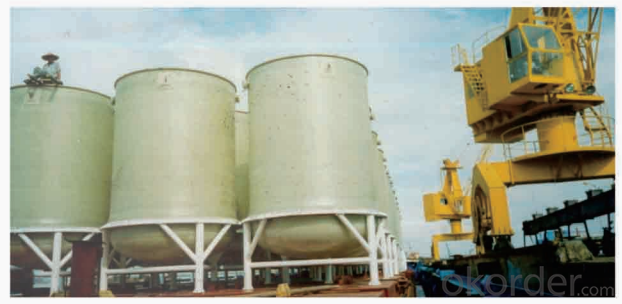

(1) Producer of the largest diameter FRP tank in Asia

On June 3, 2004, zhongfu Lianzhong contracted a 25m diameter and 2000 cubic volume super-large FRP tank, which was manufactured in the deep desert about 230 kilometers west of Golmud city, Qinghai Province. The volume of this tank not only created the first in Asia, its diameter also created the world's largest; In addition, the diameter of 20 meters made by our company in 2010,2 sets of 5000 cubic meters; A 3000 cubic meter glass fiber reinforced plastic salt acid tank with the largest volume in the world has been delivered to the owner. The product quality and construction period have been well received by the owner

(2) Advanced equipment (patent certificate), mature process

In 1995, Lianzhong group was the first to import a microcomputer controlled, double-wound, vertical winding large storage tank manufacturing equipment from Tankinetics of the United States and signed a buy-out price contract in China. The machine is the only one of the large microcomputer controlled field vertical winding machine in China, and has obtained the national patent certificate. For more than ten years, employees of Lianzhong Group have successfully completed some large and difficult projects at home and abroad, such as more than ten 1000 cubic tanks of Yantai Wanhua, two 2000 cubic tanks of Linyi Xianglong Shikefeng Group and 25m diameter 2000 cubic tanks of Qinghai Citic Guoan Water Resources Development Company.

(3) Product patents and honors

The tank bottom structure of large storage tank developed by our company obtained the national patent certificate in October 2007. For many years, the vertical winding large storage tank has obtained a series of authoritative certificates such as the national key new products issued by the Ministry of Science and Technology and the high-tech products certification issued by the Science and Technology Commission of Jiangsu Province.

(4) Drafting national standards

On September 22, 2007, the National Development and Reform Commission announced no. 60 of 2007, which approved HG/T3983-2007 standard of Chemical Corrosion Resistant Field Wound FRP Large Containers drafted by Zhongfu Lianzhong was officially released.

Product Application(Industrial sectors):

Chlor-alkali industry, sulfur-based compound fertilizer industry; Epichlorohydrin, fluorine chemical industry; Silicone/polysilicon industry; Pesticide industry; Chloromethane industry; Paper industry; Iron and steel/smelting (copper smelting, lead and zinc smelting, electrolytic nickel, electrodeposited nickel, dynamic wave system); Phosphoric acid/ammonium phosphate; Oilfield sewage; Brewing; Lactic acid; Seawater desalination; Tap water industry, etc.

Advantages & Properties in food & Flavouring Field:

FRP food containers and fermentation equipment have been widely used in the food brewing industry for their good corrosion resistance, meet the national standards for food containers, good insulation performance, long service life, low price, no need for late maintenance, beautiful appearance, light weight and high strength, etc. Lianyungang Zhongfu Lianzhong adopts imported computer-controlled fiber winding equipment, has a mature design team, first-class testing equipment, experienced production personnel and logistics service personnel. Zhongfu Lianzhong's hardware and software strength is leading in China. For the storage tanks used in the food industry, we ensure that the products meet the food hygiene standards for all the original and auxiliary materials selection purpose: to the most demanding temperature, pressure, fatigue resistance requirements for the basis of structural design, to ensure product safety and reliability; The unique 250 cubic meter high temperature curing furnace of Lianzhong company is a material guarantee to fully cure the storage tank, further reduce food residues and ensure food hygiene performance to meet the standards.

Main application:

1. Brewing soy sauce, brewing vinegar, bean sauce, chili sauce, MONOsodium glutamate and other industries; Sauce mash fermentation tank, douban fermentation tank, hot sauce drying tank, soy sauce and vinegar storage tank, high temperature resistant storage tank (used for sterilization and disinfection), brine tank, hot water and cold water storage tank, insulation tank, transport tank, fermentation tank, neutralization tank, factory brine pipeline

2. Yellow rice wine, white wine, cooking wine, rice wine industry; Curing tank, finished product tank, alcohol storage tank

3. Lactic acid, dairy industry; Lactic acid storage tank, pure water storage tank

4. Monosodium glutamate, insulating acid; Acidolysis reactor, storage tank

5. Citric acid industry: pressure ion column, storage tank

6. Collagen production enterprise; Hydrolysis fermentation tank, storage tank

7. Electronics and water treatment industry; Pure water, ultrapure water storage tank, medium water storage tank

Quality policy:

Zhongfu Lianzhong Group took the lead in the domestic industry through the ISO9001:2000 quality management system certification. Every step of the production of Zhongfu Lianzhong is under strict control, from raw materials into the factory to products leaving the factory. These control processes generally include raw material testing, production process control and finished product inspection and other three main parts.

Zhongfu Lianzhong Group has the first-class physical and chemical laboratory in the industry, with more than 100 sets of various testing equipment, the industry's only microcomputer controlled large-caliber pipeline testing machine, magnetic thickness gauge imported from Germany, etc., can be in accordance with DIN, ASTM, ASME, AWWA,BS, JIS and domestic standards for raw material testing and physical properties of products, such as internal pressure blasting test, stiffness test, heat resistance test, resin thermal deformation temperature test, viscosity test, chemical resistance test, glass fiber strength test and A series of tests, the laboratory was rated as A class laboratory by the Ministry of Chemical Industry.

The structural characteristics of the product:

1. With excellent mechanical and physical properties, the material density of FRP products is usually 1.8-2.1g/cm3, about 1/4 of steel, than steel, cast iron and plastic and other materials are high specific strength, thermal expansion coefficient and steel roughly equal, thermal conductivity coefficient is only 0.5% of steel.

2. Chemical corrosion resistance, long service life · GLASS fiber reinforced plastic has special chemical corrosion resistance, in corrosive medium places, glass fiber reinforced plastic shows incomparable advantages of other materials.

3. High strength and excellent structural performance can adjust the physical and chemical properties of FRP products by changing the resin system or reinforcement materials to adapt to the needs of different media and working conditions.

4, light weight, very convenient installation

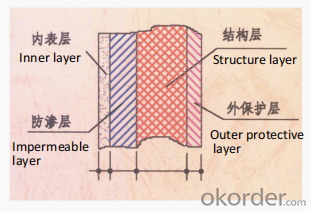

Reasonable layering structure is a good guarantee of strength and corrosion resistance of FRP. At the same time, the whole molding method is adopted, so that the equipment will have more perfect corrosion resistance and strength bearing capacity. Large equipment is mainly: lining layer (inner layer, Impermeable layer)+ structural layer + outer protective layer layering structure.

1, Inner layer: by lining resin and organic fiber polyester felt/FRP fiber surface felt enhanced, resin content of more than 90%, good air tightness, very smooth. The layer mainly provides products with anti-corrosion, anti-leakage and other functions. Its thickness is about 0.5mm

2, Impermeable layer: by lining resin and non - alkali glass fiber jet yarn composition. Resin content 70~80%. The main function of this layer is to protect the inner surface layer, improve the internal pressure failure resistance of the lining and prevent the crack diffusion. Impermeable layer and inner surface layer are collectively referred to as inner lining layer, the total thickness ≥4.5 mm

3. Structural layer: the roving yarn with no alkali and no twist is wetted by the resin of the structural layer and then wound by the method of spiral + annular + unidirectional cloth. The resin content of this layer is usually about 30~40%. The function is to withstand compressive stress, tensile stress and various external loads. The wall thickness is determined by reasonable and scientific optimization calculation according to the condition of equipment stress. Fiber winding products have the characteristics of high strength and stiffness, good mechanical properties, and can adjust the winding Angle according to the different use environment and pressure of the equipment, good designability, high quality and stable products.

4, The outer protective layer: because the layer exposed in the atmosphere, vulnerable to light oxygen and climate aging, the design of the layer with aging resistant gelcoat spraying again, while adding UV-9 UV absorber in the resin to prevent light oxygen aging. The thickness of the layer is about 1mm

The first project case in the industry created by LZFRP:

In 1995, Zhongfu Lianzhong imported vertical winding equipment for large glass fiber reinforced plastic (FRP) tanks from TANKINETIC, an American company. The equipment is manufactured in the field with a diameter of 30 meters and a volume of 10,000 cubic meters by using spiral and circular winding technology, and has signed a equipment purchase contract with a domestic buyout price. For more than ten years, zhongfulian employees have successfully completed some large, difficult and representative projects at home and abroad, and successively created a number of domestic no.1 projects:

1 In June 2014, Zhongfu Lianzhong successfully produced 6000m3 large FIBERglass storage tank (4 DN21000*16000) for Yantai Wanhua Polyurethane Co., LTD.

2 In October 2012, Zhongfu Lianzhong successfully produced ningbo Wanhua Polyurethane Co., LTD. 6000m3 large FRP storage tank (3 DN21000*16000)

3 In March 2011, Zhongfu Lianzhong successfully produced jiangsu Haixing Chemical Co., LTD. 6000 cubic large FRP storage tank (2 DN21000*16000)

4. On March 19, 2010, Zhongfu Lianzhong successfully bid for the largest single glass fiber reinforced plastic tank in the world :2 sets of 5000 cubic meters; One set is 3000 cubic meters with a diameter of 20 meters. At present, this project has been successfully delivered to the owner

5. In 2009, we successfully produced the largest FRP storage tank in the compound fertilizer industry with the largest single volume and the largest tank area (5 DN14000*13000 FRP storage tanks).

6 in 2005, we successfully produced the largest FRP hydrochloric acid tank area in China (5 DN11000*11000 FRP hydrochloric acid tanks; 3 DN14000*12000 GLASS reinforced plastic hydrochloric acid storage tanks)

In 2003, we successfully produced the largest FRP tank in China, with a diameter of 25 meters and a volume of 2000 cubic meters

8. In 2002, the largest FRP hydrochloric acid tank area in China was successfully produced (6 DN11000*11000 FRP hydrochloric acid tanks)