Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:3000 m²

Supply Capability:800000 m²/month

Ceramic Fiber Paper Type 1260℃ STD or HP

Structure of Ceramic Fiber Paper Description

Ceramic fiber is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic fiber paper has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fiber paper also has difference,and they are suitable for different workong temperatures.

Ceramic fiber can be used after optional cutting .When ceramic fiber paper storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

We are the main supplier for

Allied mineral products, inc

Refractories incorporated

Srs sorg refractory systems gmbh,

Sunward refractories co., ltd

Lilama69-1 joint stock company etc.

Main Features of the Ceramic Fiber Paper

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Ceramic Fiber Paper

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

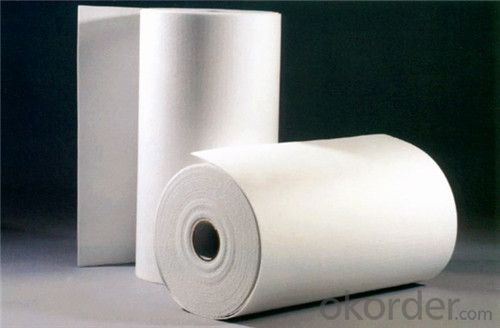

Ceramic Fiber Paper Images

◆Breif Images

◆Packaging

◆Product Process

Ceramic Fiber Paper Specification

Type | Ordinary | Standard | High Purity | High Aluminium | Zirconia | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | < 1000 | 1050 | 1100 | 1200 | 1350 | |

Color | white | spotlessly white | spotlessly white | spotlessly white | spotlessly white | |

Density (kg/m3) | 96 | 96 | 96 | 128 | 128 | |

Shrinkage on heating (%) (24 hours,density as 128/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.09(400°C) | 0.09(400°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) | 0.16(800°C) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

Why us

Professional ceramic fiber manufacturer. We have being specialized in producing refractory ceramic fiber for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

FAQ of Ceramic Fiber Paper

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!