Loading Port:Qingdao

Payment Terms:TT or LC

Min Order Qty:3000 pc

Supply Capability:100000 pc/month

Industrial Furnace Heat Lining Ceramic Fiber Module Refractory / Insulation

Product Description:

Ceramic fiber is made from high quality clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber has a range of products: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products use different materials. The performance of ceramic fiber is also different, and they are suitable for different working temperatures.

Ceramic fiber can be used after optional cutting. When storing ceramic fiber, pay attention to moisture. The high-alumina type and containing zirconium type products can be directly used as furnace linings.

Product Features:

• Low thermal conductivity

• High tensile strength

• Resilient to thermal shock

• Corrosion resistance

Product Specifications:

Al Content (%): 32-55

Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

Density: 64-160kg/m³

Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Product Packing:

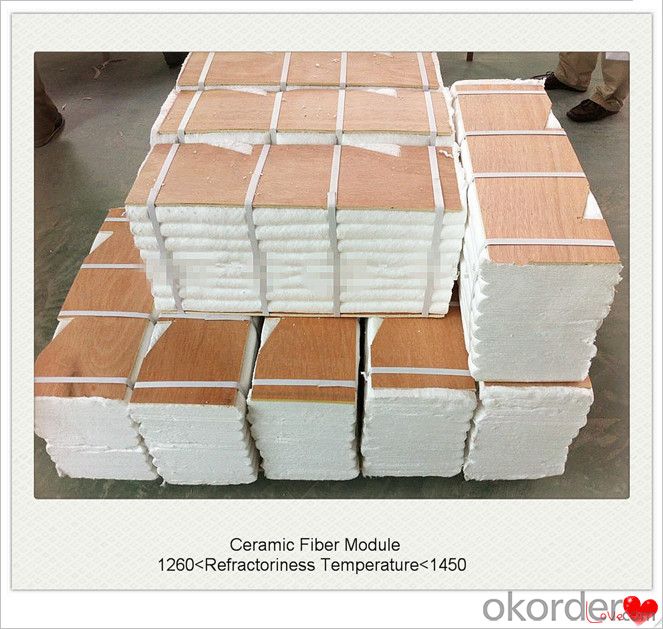

Plastic bag in a carton box

Product Images:

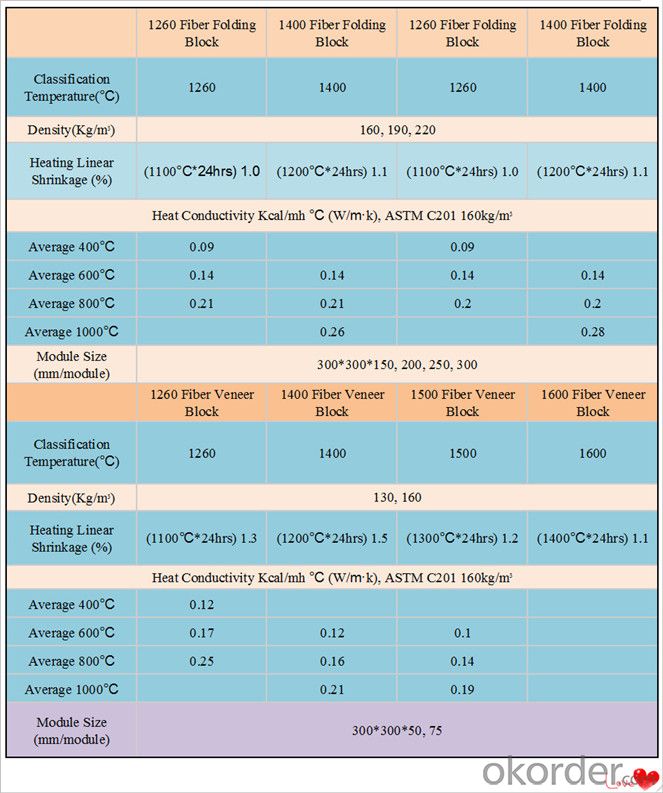

Techincal Data for Ceramic Fiber Module

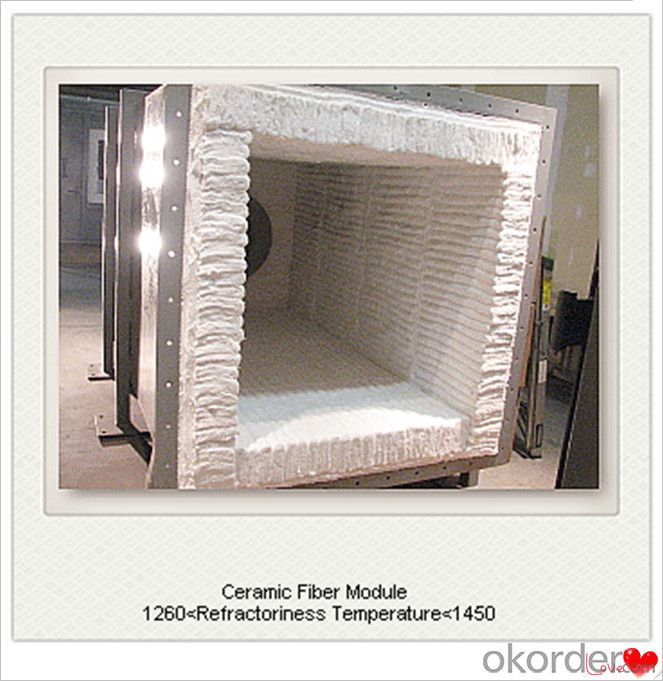

Images for Ceramic Fiber Module

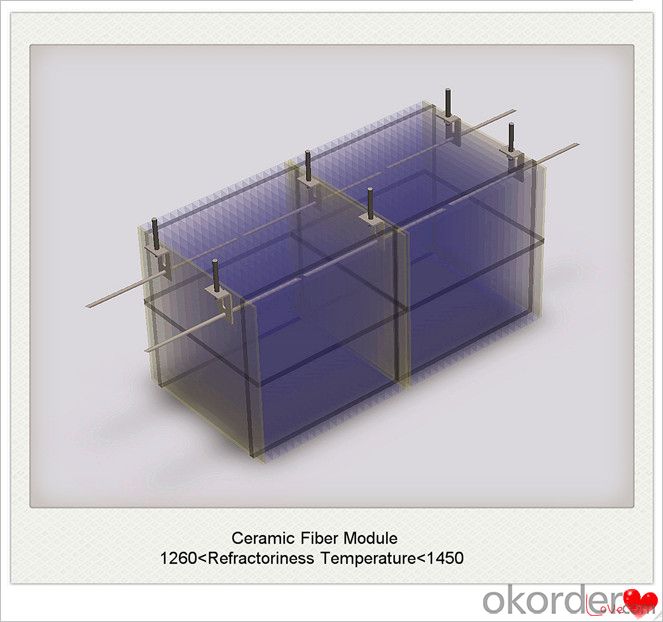

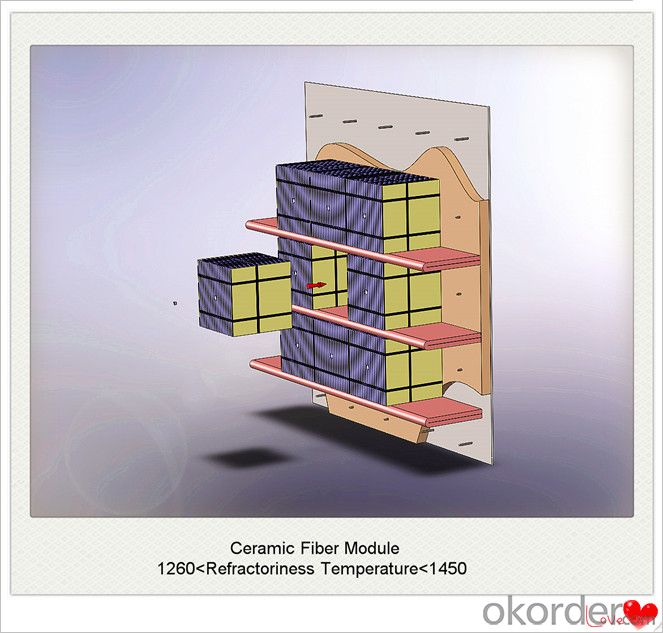

3D Drawinng for Anchorage of Ceramic Fiber Module

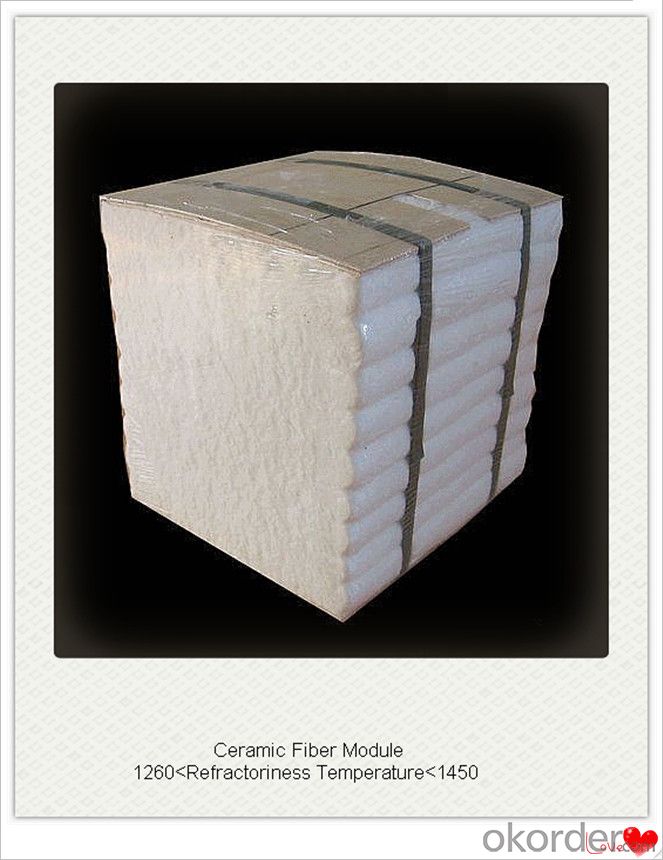

Packaging and Delivery for Ceramic Fiber Module

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.