Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 pc

Supply Capability:10000 pc/month

Ceramic Fiber Board for Fireplace 1260C

Product Description

General Information

Ceramic Fiber Board is a lightweight refractory material processed with alumina-silica fibers for applications at temperatures up to 1430°C(2600°F)

Ceramic fiber board is a vacuum formed product that resists higher gas velocities than ceramic fiber blanket,it is ideal for furnace,boiler duct and stack lining due to its low thermal conductivity and low heat storage allowing shorter cycle times and quicker access for maintenance

Features

1.Low thermal conductivity

2.Iow heat storage

3.Excellent thermal shock resistance

4 Auto production lines

5.Easy to cut

Application

1.Refractory lining for industrial furnaces in walls,roofs,doors,stacks,etc.

2.Combustion chamber liners,boilers and heaters

3.Back-up insulation for brick and monolithic refractories

4.Transfer of molten aluminum and other non-ferrous metals

5.Expansion joint boards

6.Barrier against flame or heat

7.Hot face layer for high velocity or abrasive furnace atmosphere

CERAMIC FIBER BOARD ---STD

Classification Temperature (℃) | 1260 |

Working Temperature (℃ ) | 10 00 |

Color | White |

Bulk Density (kg/m3 ) | 240-300 |

Thermal Conductivity(W/m.k) | |

400℃ | 0.067 |

600 ℃ | 0.094 |

800 ℃ | 0.136 |

1000 ℃ | 0.152 |

1200 ℃ | 0.190 |

1300 ℃ | - |

Thermal Shrinkage 24hrs (%) | 1200℃ |

-3.3 | |

Chemical Composition (%) | |

Al2O3 | 45-47 |

Al2O3+ SiO2 | 97-98.5 |

Note: Technical Data are typical results from test pieces. This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

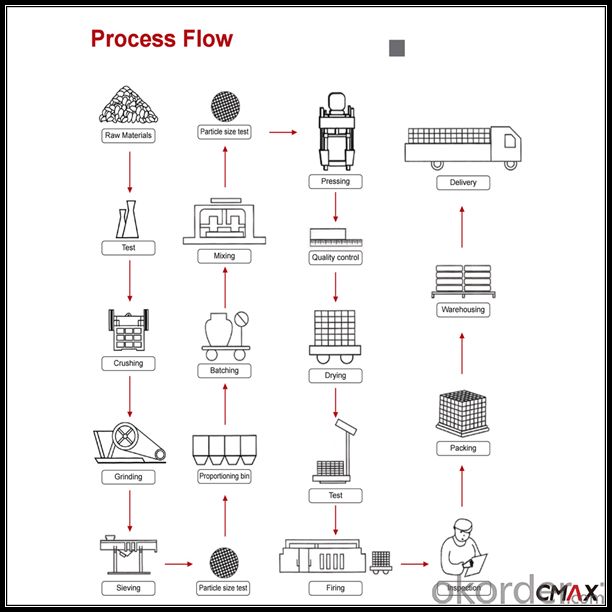

Ceramic Fiber Board Process Flow

Packaging & Shipping

Packaging Details: Wrapped by plastic bag and then put into carton box designed for export.

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research,development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection,supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Competitive Advantage:

The most advanced full auto equipment and strictly QC control system could guarantee quality to meet the requirements of the local and international markets ,and we are famouse for the safe package and prompt delivery.

Company Information

CNBM (China National Building Material) Group is the largest comprehesnsive building materials group in China that in intergrate scientific research,manufacturing and logistics into one entity.the largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields,CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.If any question, please contact us freely.