Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 pc

Supply Capability:200 pc/month

Main application and scope

Model CD, MD wire rope Electric Hoist is a small-sized and light lifting equipment, which can be mounted on single beam、bridge、gantry and jib crane. With slight modification, it also can serve as winch. Thus, it is widely used in factories、mines、harbors、warehouse、cargo storage areas and shops.It is essential in raising working efficiency and it also can improve working conditions.

Model CD Electric Hoist has only one normal speed, which can satisfy normal supplication. MD Wire rope Electric Hoist is provided two speeds: normal speed and low speed. At a low speed, it can do precise loading and unloading、mounding of sand box、maintenance of machine tools and etc. Thus, MD Wire rope Electric Hoist is more widely used than Model CD.

To meet the needs of lifting heavier cargo, our factory manufactures WH20T and WH32T Electric hoist.

The difference between CD and MD

1.The lifting speed of the CD model is constant speed, which can fit the general requirements.

2.MD model has two lifting speeds - normal speed and slow speed.

3.When it slow work, can meet the requirements of precision loading and unloading , sand box mold, machine repair and other fine operations. Therefore, the use of MD electric hoist more widely than the CD electric hoist.

4.MD model price is more expensive than CD model.

Safety and working conditions

The working environment temperature of this product is between -20 and +40 degrees centigrade. It is not suitable for the workplace where there is explosion danger, fire danger, acid or other corrosive gas and relative humidity is greater than 85%. Not for manned use. The operation shall be carried out in strict accordance with GB6067-1985 "crane safety regulations".For use in open spaces, protective devices shall be provided against moisture.

The product load sustained rate of FC25%, starting times 120 / hour.

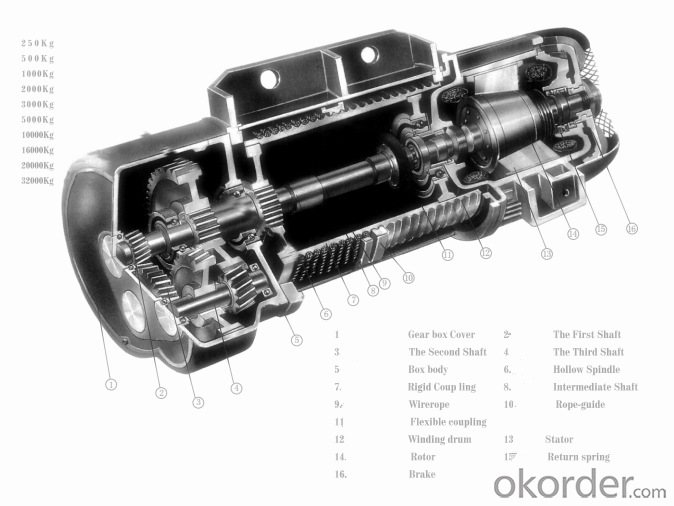

The main structure and working principle of Model CD/MD electric hoist

Model CD/MD electric hoist is mainly composed of three parts: lifting mechanism, running mechanism (stationary type) and electrical control device

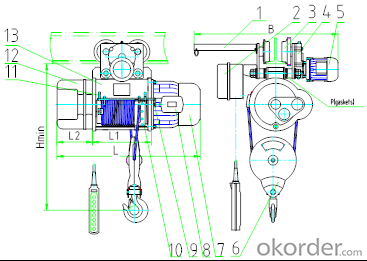

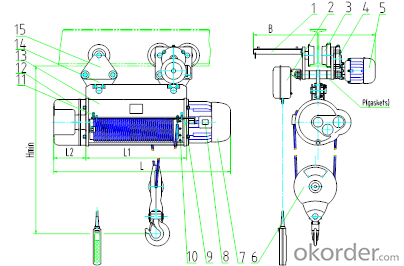

Model CD/MD electric hoist appearance structure

1. soft cable introduction frame

2. electric control box

3. trolley

4. reducer

5. electric motor

6. lifting hook

7. lifting motor

8. fire stopper

9. limited rod

10.rope guide

11.stop block

12.hoisting reducer

13.roll device Figure 1a: CD Model electric hoist 0.5t H=6m-12m

14.trolley equalizer

15.two wheel trolley

Installation method

First, you need to install the chain box first.

Second, connect the power cord.

When connecting the power cord, must be cut off the power in advance.The ground line should be well grounded at same time, otherwise the operator may feel electric shock when touching any part of the gourd or chain.

Third, the load chain of Lubricated ring chain electric hoist

The lubrication degree of chain is an important factor affecting the service life of load chain.Timely and effective lubrication of load chain can guarantee the effective service life of the chain.

Fourth, check the chain alignment

For multi-chain ring chain electric hoist, should make sure that the hook rack is not flipped.If flipped, return it to normal and ensure that the chain is arranged in line.Do not hang the load on the chain's twisted gourd.

Finally, check the working voltage

Because of the link chain electric hoist out of the factory, they are made according to the user specified voltage or high voltage equipment (only for dual voltage), such as 230/460 v, the operator to check and confirm whether meet the requirements of power supply voltage.If not, please refer to the instructions to meet the required working voltage requirements.

CD1 MD1 | ||||||||||

Lifting capacity(t) | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | ||

Hoisting height(m) | 3/6/9 | 6/9/12 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 9/12/18/24/30 | 9/12/18/24/30 | |||

Hoisting speed(m/min) | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | |||||||

Traveling speed(m/min) | 20 | 20/30 | 18 | |||||||

Wire rope | Dia (mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 17.5 | ||

specification | 6*19 | 6*37 | ||||||||

Track | 10-20b | 16-28b | 20a-32c | 25a-50b | 32b-50b | 32b-63c | ||||

Min. Curvature radius(m) | 0.8 | 1.5 | 1.5/2/3/4 | 2/2.5/3/4 | 2/2.5/3/4 | 2.5/3/4/4.5/6 | 3.5/4/6/7.5/9 | 3.5/4/6/8/11 | ||

Type | ZD₁12-4 | ZD₁21-4 | ZD₁22-4 | ZD₁31-4 | ZD₁32-4 | ZD₁41-4 | ZD₁51-4

| |||

ZDS₁0.2/0.8 | ZDS₁0.2/1.5 | ZDS₁0.4/3.0 | ZDS₁0.4/4.5 | ZDS₁0.8/7.5 | ZDS₁1.5/13

| |||||

0.4 | 0.8(0.2/0.8) | 0.2(0.2/1.5) | 3.0(0.4/3.0) | 4.5(0.4/4.5) | 7.5(0.8/7.5) | 13(1.5/13) | ||||

1380 | 1400 | |||||||||

1.25 | 2.4(0.72/2.4) | 4.3(0.72/4.3) | 7.6(1.25/7.0) | 11(1.25/11) | 18(2.4/18) | 30(5.2/30) | ||||

Type | ZDY₁10-4 | ZDY₁11-4 | ZDY₁12-4 | ZDY₁21-4 | ||||||

Power(RW) | 0.06 | 0.2 | 0.4 | 0.8 | ||||||

Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | ||||||

Current (A) | 0.3 | 0.72 | 1.25 | 2.4 | ||||||

No. Of connecting | 120 | |||||||||

Duty classification | Intermediate FC=25% | |||||||||

Power source | Three-phase AC 380 V50Hz | |||||||||

L | 391 | 616/688/760 | 758/856/954/1150/1346/1542 | 820/920/1020/1220/1420/1620 | 932/1038/1138/1327/1533/1738 | 1047/1157/1257/1467/167//1887 | 1602/1783/2145/2507/2869/1872/2092/2532/2952/3387 | |||

L1 | Basic Dimensions (mm) | 78 | 274/364/418 | 345/443/541/737/933/1129 | 352/452/552/752/952/1152 | 380/483/586/792/998/1204 | 415/525/625/835/1045/1255 | 875/1056/1418/1780/2142/1136/1356/1796/2216/2651 | ||

216 | 125 | 158 | 187 | 229 | 267 | 301 | ||||

L3 | 318/390/462 | 401/499/597/793/989/1185 | 418/518/618/818/1018/1218 | 448/551/654/860/1060/1272 | 485/606/695/905/1115/1325 | 949/1130/1492/1854/2216/1210/1430/1870/2290/2725 | ||||

L4 | 190 | 196 | 240 | 264 | 320 | 376 | ||||

B | 279-315 | 884 | 930 | 1055 | ||||||

H | 423 | 650 | 667/767 | 840/950 | 954/1058 | 1120/1183 | 1350 2100 | |||

d | 17 | 20 | 25 | 25(31) | 25(37) | |||||

b | 185 | 185/270/470/660/860 | 205/280/480/680/880 | 205/320/530/730/940 | 228/340/550/760/920/ | 490/670/1030/1395/1760/860/1080/1520/1940/2375 | ||||

CD1 | Crane weight (KG) | 44/45/46/ | 121/125/130 | 137/145/172/188/204/220 | 221/232/285/309/332/353 | 281/297/354/390/420/451 | 437/495/597/646/686/726 | 1048/1098/1209/1301/1411/1130/1183/1286/1463/1563 | ||

/MD1 | 138/142/147 | 164/174/199/215/231/247 | 256/267/320/344/361/388 | 311/327/384/420/450/481 | 508/532/654/703/743/783 | 1104/1154/1265/1366/1467/1220/1273/1376/1553/1653 | ||||

CD1(FIXED) | 30/31/32 | 89/94/99 | 105/112/120/135159/165 | 166/179/186/209/229/249 | 222/236/250/284/312/340 | 377/400/415/456/493/529 | 795/841/943/1035/1127/850/903/1006/1183/1283 | |||

MD1(FIXED) | 106/111/116 | 132/140/147/162/177/192 | 201/211/221/244/264/284 | 252/266/280/314/342/370 | 430/457/472/513/549/586 | 851/897/999/1091/1183/949/997/1090/1273/1373 | ||||