Loading Port:China main port

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:30 unit/month

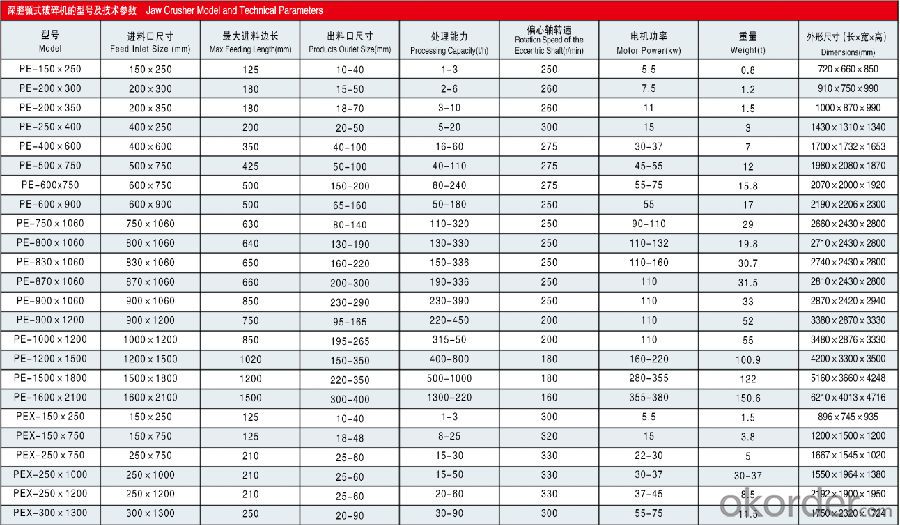

The jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials, and can crush materials with compressive strength not more than 320Mpa, which are divided into coarse and fine broken. PE series jaw crusher has complete specifications and its feeding size is 125mm~1200mm. It is the ideal equipment for primary crushing. Jaw Crusher is widely used in mining, metallurgy, building materials, roads, railways, water conservancy and chemical industries. The large and medium-sized jaw crusher is one of our company's fist products, especially in the design and production of large jaw crushers, which are at an advanced level at home and abroad.

Performance and features:

1. Deep cavity setting and no dead zone, improving feeding capacity and output;

2. The crushing ratio is large and the product granularity is uniform;

3. The gasket type discharge port adjusting device is reliable and convenient, and the adjustment range is large, which increases the flexibility of the device;

4. The lubrication system is safe and reliable, the parts are easy to replace, and the maintenance workload is small;

5. The structure is simple and reasonable, the work is reliable, and the operating cost is low;

6. The equipment is more energy-efficient: the energy saving of the single machine is 15%~30%, and the system energy saving is more than double;

7. The discharge port has a large adjustment range to meet the requirements of different users;

8. Low noise and less dust.

working principle:

When the jaw crusher is working, the motor drives the belt and the pulley, and the eccentric shaft moves the movable jaw up and down. When the moving jaw rises, the angle between the bracket and the moving jaw becomes larger, thereby pushing the movable jaw to approach the fixed jaw, and At the same time, the material is crushed, smashed, milled, etc.; when the moving down, the angle between the bracket and the moving raft becomes smaller, and the moving slab leaves the slab under the action of the tie rod and the spring, and the material has been pulverized. Under the action of gravity, the discharge port at the lower part of the cavity is freely discharged. Therefore, the jaw crusher works intermittently, and the crushing and discharging processes alternate in the bore cavity. Mass production is achieved as the motor continuously rotates and crushes the machine for periodic crushing and discharging.