Loading Port:Qingdao

Payment Terms:TT or LC

Min Order Qty:10 m.t.

Supply Capability:100000 m.t./month

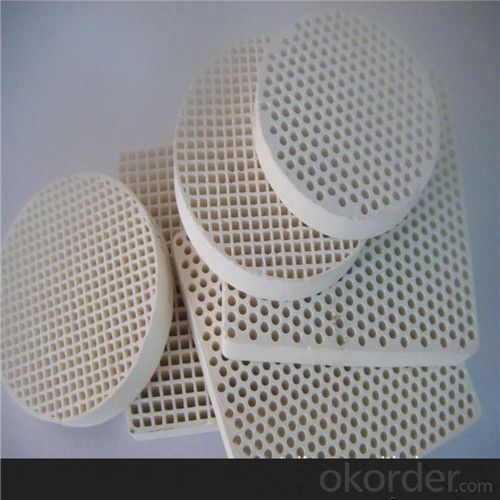

General Information of Ceramic Foam Filters

Alumina ceramic foam filters are widely used in filtering the alumina and alloys in foundries. With 80-90% porosity, the filters can effectively remove the alumina dross to improve the casting quality.

Features of Ceramic Foam Filters

Improving the steel casting quality

Excellent thermal shock resistance

High porosity with good strength

High efficiency to filter the steel dross

Tailored sizes as customer’s requirement

Image of Ceramic Foam Filters

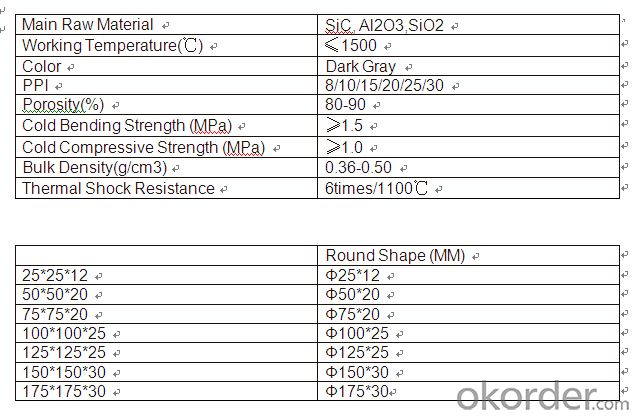

Technical Data of Ceramic Foam Filters

Applications of Ceramic Foam Filters

Carbon steel casting, steel alloy casting and stainless steel casting

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.