Loading Port:China Main Port

Payment Terms:TT or L/C

Min Order Qty:1 set set

Supply Capability:100 Sets Per Month set/month

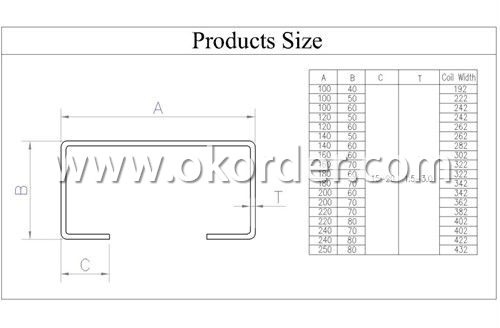

Specifications of C-Section Roll Forming Machine

General Information of C-Section Roll Forming Machineof C-Section

Roll Forming Machine

This C-Section roll forming machine is full-automatically controlled by PLC, the whole hydraulic transmission, drive hydraulic oil jar carry out and shear through centre pump station towards the hole,hydraulic pressure motor transmit power as main transmission. We can produce according to your drawings.

This roll forming machine is the special high speed roll forming machine for steel sheet cold-form industries. It has pressing system and can continuous form the steel sheet according to customer’s requirement, automatically cut to length. This equipment has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good look and so on.

1 use to different sheet product

2 high quality and competitive price.

3 easy operation

4 With fewer people, save space

Working flow

Decoiling→feeding steel strip →sheet leveling→punching to length→Cut to length →roll forming →run out table

Technical parameter

Item |

Parameter | |

Suitable material |

Type |

galvanized sheet |

Thickness |

0.4-0.8 (mm) | |

Yield stress |

235-345(Mpa) | |

Machine material |

Hole puncher |

Cr12 quenched |

Roller |

GCr15 quenched | |

Cutting Blade |

Cr12 quenched | |

Power Requirement |

Type |

380V/3PH/50HZCustomize |

Main Motor |

15kw | |

Hydraulic |

7.5kw | |

Hydraulic Cantilever

De-coiler |

Type |

Hydraulic automatic |

Max Capacity |

3000kgs | |

Suitable OD |

1200mm | |

Suitable ID |

508/610mm | |

Max Width |

500mm | |

Motor Power |

4.0kw | |

Hydraulic Power |

2.2kw | |

Forming Speed (Excludes cutting & punching) |

20-25m/min | |

Forming Stand |

About 14 group | |

Transmission |

Chain,sprocket | |

Type of Cutting |

length-set cutting | |

Control System |

Mitsubishi PLC& transducer | |

| Packaging Detail: | Bare packing,with computer control cabinet is to be boxed. This line can be put into one 20feet container. |

| Delivery Detail: | 35 working days after receiving advance payment. |