Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:100 set

Supply Capability:80000 set/month

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk.The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. A butterfly valve consists of body ,stem ,disc , actuator (manual actuator, worm-gear actuator , aerodynamic actuator or electric actuator) , and wafer type butterfly valve can implement the process for turning on turning off and regulating the flow by the circumrotation of stem and disc that is droved by actuators.

2.Main Features of the Manual Wafer Butterfly Valve

Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

Excellent sealing performance with no leakage. Long service life.

Wide selection of materials ,applicable for various media..

Working Temperature : -45 C centigrade-+200C centigrade

Suitable Mediums : Fresh water, Sewage, Sea water, Air, Oils, Acids, Alkalis, Salts, etc.

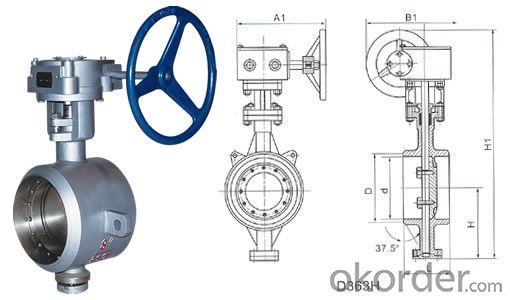

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.