Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:1 pc

Supply Capability:9999 pc/month

Quick Details

Standard or Nonstandard: Standard

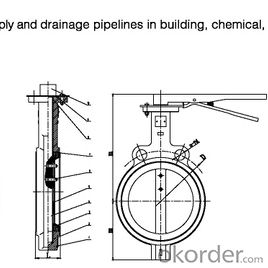

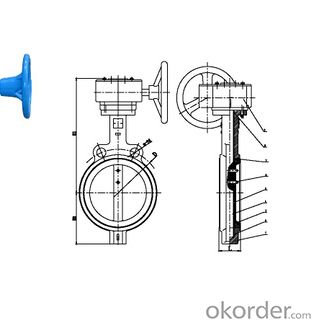

Structure: Butterfly

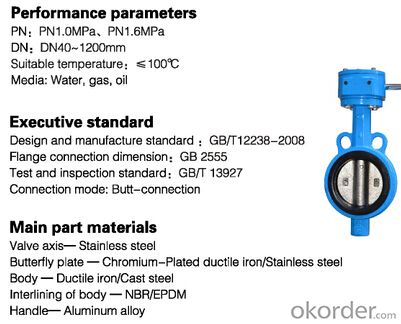

Pressure: Low Pressure

Power: Manual

Material: Casting

Temperature of Media: Normal Temperature

Media: Water

Port Size: DN40-DN1200

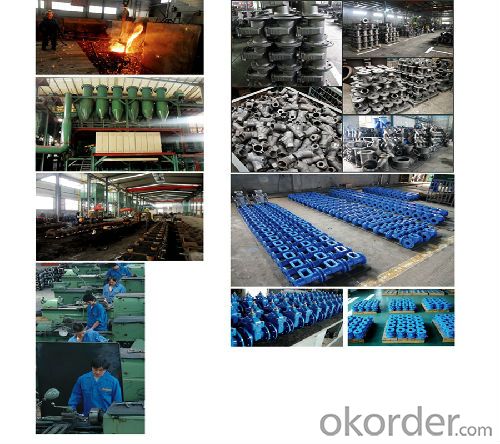

Place of Origin: China (Mainland)

Wafer type: butterfly valve

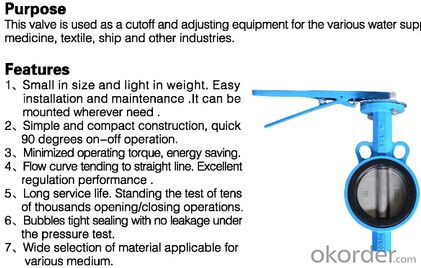

Butterfly features:

1. Small and light , and easy installation and mintanance. It can be mounted wherever needed.

2. Siple and compact construction, quick 90 degree on-off operation.

3. Miniminzed operating torque, energy saving.

4. Flow curve tending to straight line. Excellent regulation performance.

5. Long service life Standing the test of tens of thousands opening/closing operations.

6. Bubbles-tight sealing with no leakage under the pressure test.

7. Wide selection of materials, applicable forvarious medium.

Delivery Detail: Within 20 days

Specifications

Wafer type lined butterfly valve

1.Design standard:ISO,BS,API

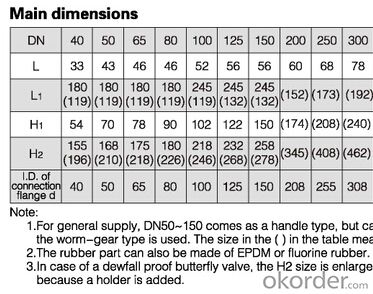

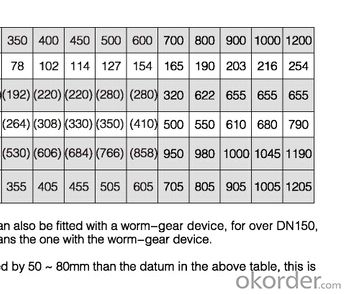

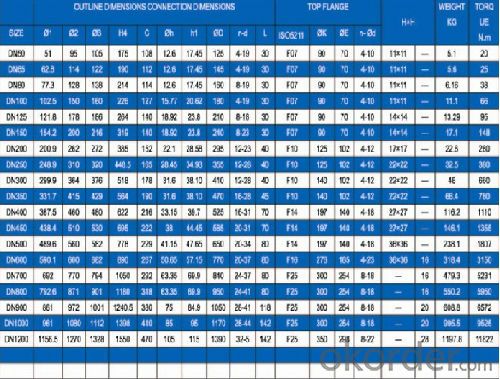

2.DN40-DN1200

3.PN10/PN16/PN25

4.Center lined disc

Wafer type lined butterfly valve

Technical Data

DN40-DN1200mm PN1.0-1.6MPa

General Design:ISO 5752 / BS 5155 / API 609

Body: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel

Seat: EPDM, PTFE, NBR,Viton

Stem: Stainless Steel, Steel,

Disc: Ductile Iron with Nickel Coating,Ductile Iron with Nylon Coating, Stainless Stee 304/316l, Alu-Bronze,Duplex steel

Flange Connection:DIN,ANSI,JIS,BS

Product Features

Wafer type flanged body style fit between FF or RF flanges

PTFE bushing ensure the maximum shaft support and centralized alignment

360°polished disc assures positive on-off

Hard-Backed Cartridge seat or Edge-Boot seat

The pin,spline or square connection are all available

Universal ISO 5211 mounting pad.

Brief of butterfly:

Butterfly valve can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

There are different kinds of butterfly valves, each adapted for different pressures and different usage. The zero offset butterfly valve, which uses the flexibility of rubber, has the lowest pressure rating. The high performance double offset butterfly valve, used in slightly higher-pressure systems, is offset from the cen tre line of the disc seat and body seal (offset one), and the centre line of the bore (offset two). This creates a cam action during operation to lift the seat out of the seal resulting in less friction than is created in the zero offset design and decreases its tendency to wear. The valve best suited for high-pressure systems is the triple offset butterfly valve. In this valve the disc seat contact axis is offset, which acts to virtually eliminate sliding contact between disc and seat. In the case of triple offset valves the seat is made of metal so that it can be machined such as to achieve a bubble tight shut-off when in contact with the disc.

Packaging Details: Plactic bag+Paper cover+Plywood cases