Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:999 pc

Supply Capability:9999 pc/month

1. Manual Wafer Butterfly Valve Description:

Butterfly valve is mainly consisted of body, stem, disc, seat and driver(lever, gearbox, pneumatic and electric Actuator) and so on. On off and controlling flow of valve are made by turning stem and disc together.A butterfly valve is a valve which can be used for isolating or regulating flow.

Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow.

2.Main Features of the Manual Wafer Butterfly Valve

1)Flow curve tending to straight-line. Excellent regulation performance.

2)Small in size and light in weight and maintaince.

It can be mounted whereever needed.

3)Simple, compact structure, quick 90 degree on-off operation.

4)Disc has two-way bearing, perfect seal, without leakage under

the pressure test.

5)Various kinds of materials, applicable to different medium.

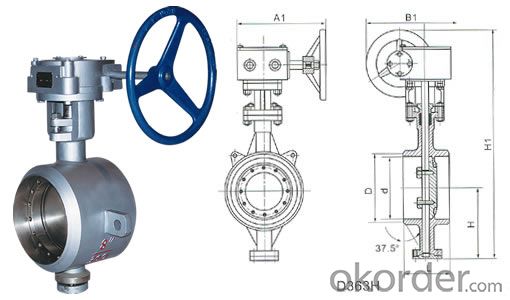

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.