Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:-

Supply Capability:-

Structure

We produce custom engineered solar tabbing and bus wire helping to attain the highest efficiencies possible for each unique module design. Our Research and Development team can assist you with your needs evaluation and our world-wide manufacturing facilities are strategically located for large volume production.

PV ribbon is composed of Copper and coating alloys, and divided into Tabbing Ribbon and Bus bar ribbon.

Tabbing Ribbon: it is commonly connects the positive and negative sides of the cells in series. Bus bar Ribbon: it is concentrate the cell stringing into junction box and channels electrical current.

Feature

1,Good solderability

2,Good straightness

3,Low yield strength

4,Low Melti

The Flux should be compounded and processed in such a manner as to be uniform in quality and should be free from deleterious material and other details that will after life serviceability or appearance.

Cold Rolling Mills for manufacturing Photovoltaic (PV) Ribbon:

Cold Rolling Mills for manufacturing Photovoltaic Ribbon

This machine is for making Bare flat copper conductors which is using PV Ribbon Wire , Tinned plated flat copper conductors which is using FFC or materials and it was designed to make the best quality products with high productivity as well as easy to control.

Machine capacity

Tinned plated flat copper conductors which is using FFC

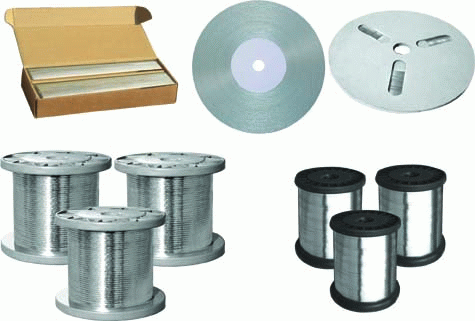

Images

Specifications

1.Raw material TU1 Cu purity>99.97%

2.TUV approved PV Ribbon

3.Sn60Pb40 coating alloy

4.Low yield strength <=70MPa

PV ribbon is composed of Copper and coating alloys, and divided into Tabbing wire and Bus bar .

1, Tabbing wire

Tabbing wire commonly connects the positive and negative sides of the cells in series.

2, Bus wire

Bus bar concentrates the cell stringing into junction box and channels electrical current

BaseCopper Oxygen Free Copper,Cu≥99.97%; Resistivity≤0.01724Ω·mm²/m

Length (20-500)±1.5mm (Only for cut ribbon)

Camber Connect Ribbon of Hand welding ≤4mm/m;Bus Ribbon of Hand welding ≤3mm/m;

Machine welding ≤8mm/m

Elongation Connect Ribbon≥15%;BusRibbon≥20%

TensileStrength Connect Ribbon≥150MPa;BusRibbon≥190MPa

Resistivityof Ribbon (1.9-2.5)×10-2Ω·mm²/m

Coating Thickness (0.01~0.04)±0.005mm of Each Side

CoatingComposition Lead:Sn60%Pb40%,Sn63%Pb37%,Sn62%Pb36%Ag2%,Sn60%Pb39.5%Ag0.5%

Lead-free:Sn96.5%Ag3.5%Bi(micro),Sn97%Ag3%,Sn96.5%Ag3%Cu0.5%;(OtherCoating Compositions can be customized according to customer requirements.)

FAQ

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.