Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:5 m.t.

Supply Capability:10000 m.t./month

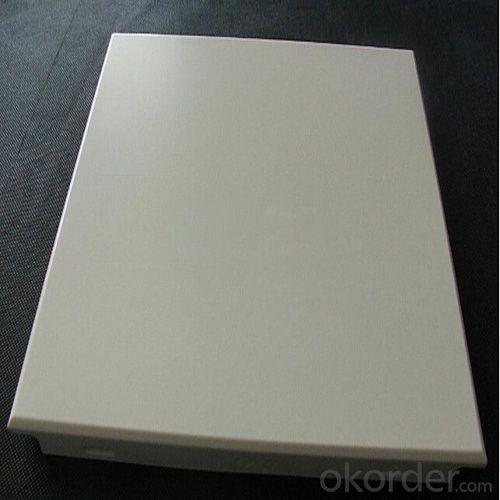

1.Structure of Bottle Cap Aluminium Sheet and Coil Description:

Aluminum Sheet for bottle closure is rolled to very fine tolerances to yield more closure per tonne of stock and to allow uninterrupted operation of high-speed, multiple-cavity presses. Such closure sheet its strength, high formability, low Earring and printable surfaces make it ideal for pilfer-proof caps and vial seals.

Closures from Signi assure long storage periods without any deterioration of the product. With suitable removal torque and high quality multicolour printing, its ROPP Closures are aesthetically unique and technically user friendly, perfect for re-sealability.

The broad categories of ROPP closures can be defined as Plain Printed Caps, Top Embossed Caps, Knurl Embossed Chamfered Caps, Side Embossed Chamfered Caps, Deep Drawn Caps, Extra Deep Drawn Side dry offset printed caps etc

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and JIS

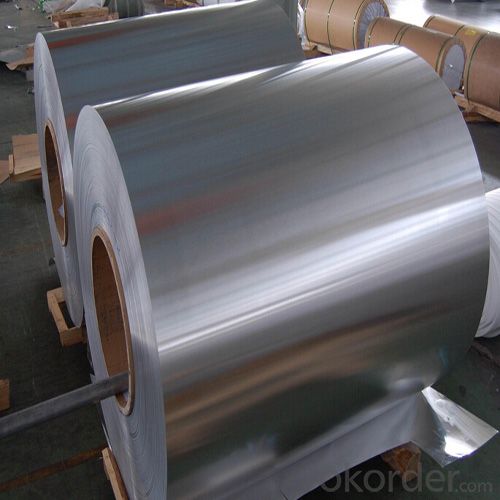

4. Bottle Cap Aluminium Sheet and Coil Specification:

| Product | Alloy | Temper | Specification | |

| Thickness (mm) | Width (mm) | |||

| Auminium sheet/plate/strip | 1,3,5,8 series | O, H1X, H2X | ≥0.1 | 800-1700 |

| Curtain wall | 1,3,5,8 series | H12, H22 H24, H26, O | 0.2-4.0 | 800-1700 |

| PS plate | 1050,1060, 1070 | H14, H18, H19 | 0.13-0.3 | 1000-1500 |

| Aluminum foil stock | 1,3,5,8 series | O, H1X, H2X | 0.2-0.5 | 800-1700 |

| Decorate material | 1,3 series | H12, H22 H24, H26 | 0.1-0.5 | 800-1650 |

| Lips cap stock | 1060, 8011 5052, 5182 | H16, H18 H19, H22 H24, H26 | 0.15-0.3 | 1700 |

| Aluminum composite panel | 1100, 3003, 8011 | H14, H16 H18, H26 | 0.2-0.35 | 1700 |

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..