Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:100 m.t.

Supply Capability:30000 m.t./month

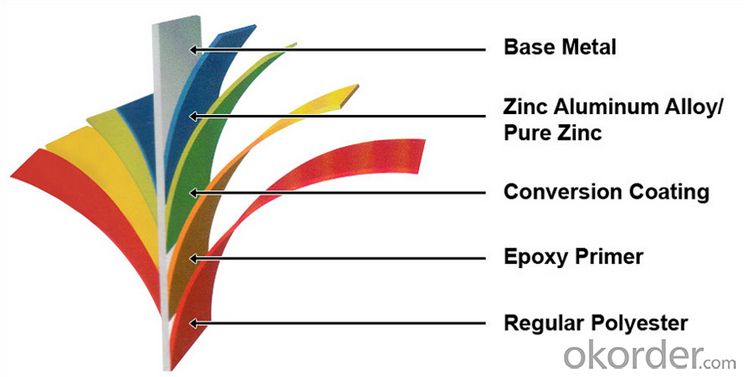

Structure of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Description of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Galvanized sheet or coil is defined as a carbon steel sheet coated with zinc on both sides. Continuous hot dipping, or electro-galvanizing are the two processes used to produce galvanized sheet and coil. Generally speaking, the hot dip process consists of passing the steel through a bath of molten zinc. The electro galvanizing process consists of the application of zinc by electrolytic disposition.The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer.

Main Feature of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

1. Resistance to Corrosion Has better performance in corrosion resistance than hot dip galvanized coil/sheet of the same thickness and its service life is 1-5 times longer than general hot dip galvanized coil/sheet.

2. Machinability Can satisfy the processing requirements of rolling, coiling and others processes alike.

3. Thermal Resistance Can sustain the environment at 315Centigrade for long time.

4. High Reflectivity Reflection ability of heat and light is twice as much as those of hot dip galvanized steel coil/sheet, and its reflectivity is more than 0.75, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction material of saving energy.

Applications of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing cars, ships,containers household electric appliances, other industries usage. |

FAQ of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2.What's your MOQ?

25MT, it is for one container.

3.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

5.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.