Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:2000 m²

Supply Capability:100000 m²/month

EPDM waterproofing roofing membrane

1. Introduction:

1.Product composition

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof

coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related

equipments which are specially designed for production of such product.It is good in compactness,

without bubble and performance difference in length and breadth,perfomances reach or exceed the demands of GB18173.1-2000 standard.

2. Advantages of epdm membrane

1>Excellent antiaging performance, service life up to 50 years

2>Working well with in 40C to 100C,it canbe constructed with a single layer in ambient temperature.

3>Waterproofing on various kinds of underground project,industrial of civil buildings and structures.

4>high extension rate, high tensile strength, small size changes at heat treatment

5>Good plant roots penetrability resistance and can be made waterproofing layer of planting roof

6>Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem .

7>Good low temperature flexibility, and good performance of adapting to ambient temperature changes.

8>Convenient application ,solid joint, no environment pollution

9>chemical corrosion Resistance, can be used for special occasions

10>Convenient maitenance, low cost.

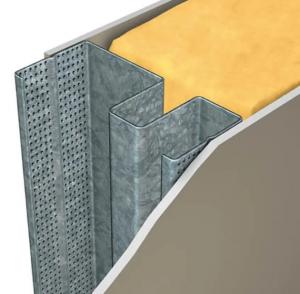

3. Application Scope of epdm membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building

waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially

to the keystone waterproofing projects which is durability, high corrosion resistance and easy

deformation.

4. Technical Data:

The item name | Indication | Applicable test items | ||||

Tension Strength (MPa) | Normal temperature≥ | 7.5 | GB6.3.2 | |||

60°C≥ | 2.3 | |||||

Elongation at break | Normal temperature≥ | 450 | ||||

-20°C | 200 | |||||

Tear strength N ≥ | 25 | GB6.3.3 | ||||

(0.3Mpa.30 min)Water tightness | No seeage | GB6.3.4 | ||||

Flexibility at low temperature ≤ | -40 | GB6.3.5 | ||||

Heat expansion (mm) | Extended ≤ | 2 | GB6.3.6 | |||

Contraction ≤ | 4 | |||||

(80°C×168h) | Fracture tensile strength retention %≥ | 80 | GB6.3.7 | |||

Hot air ageing | Keep rate tore elongation | 70 | ||||

%≥ | ||||||

Alkaline [10%Ca(OH)2Normal temperature×168h] | Fracture tensile strength retention %≥ | 80 | GB6.3.8 | |||

Keep rate tore elongation%≥ | 80 | |||||

Ozone aging | — | GB6.3.9 | ||||

Artificial climate ageing | Fracture tensile strength retention %≥ | 80 | GB6.3.10 | |||

Elongation at break %≥ | 70 | |||||

Bond peel strength | Standard test condition | 1.5 | GB6.3. | |||

4. Product Show: