Loading Port:Lianyungang

Payment Terms:TT OR LC

Min Order Qty:900 pc

Supply Capability:1000000 pc/month

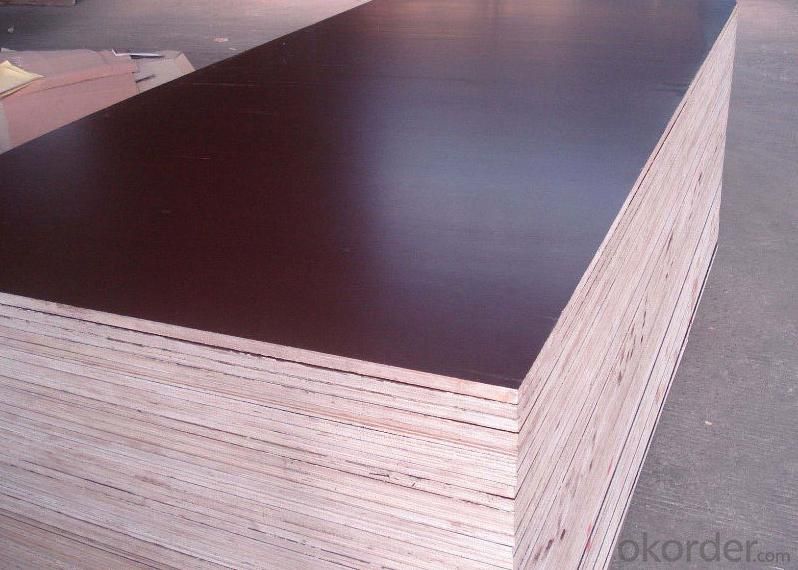

Film Faced Plywood

can be used for 5-10 times

| Packaging Detail: | Inner packing: inside pallet is covered with 0.2mm plastic bag Outer packing: by pallet, wrapped in carton, reinforced with iron belt |

| Delivery Detail: | 15Days |

film faced plywood

1 waterproof

2 UV capability not easily fade

3 Anti-scratch, anti-acid alkali

4 Environmentally, E1 gra

610*2500*20mm film faced plywood manufacturers,marine plywood

Specifications

1. More than 12 years production experience

2. More than 8 years export experience

3. Excellent after-sell service

1. Big Size: The biggest size is 2440*1220mm, 915*1830 mm, which could decrease the numbers of the joint and increase the working efficiency. And the planking will not deform and crack, it can resist water well, re-use many times and demoulds easily.

2. Light weight:It is more suitable for high-rise building and bridge construction.

3. Re-use number:For Melamine glue, usually can be used about 8 times, and for WBP glue, can be re-using above 15 times.

4. Concrete building: It can keep the surface smooth and beautiful when used for pouring, and you don’t need to plaster the wall for second time, for it can decorate directly that will decrease the construction period by 30%.

5. Corrosion resistance: It will not pollute the surface of the concrete.

6. Good moisture-retention: It is good for construction, and in winter it can be used as template for curved surface.

7. Good workability: It is better than bamboo plywood and small steel plywood in terms of nailing, sawing and drilling, it can be processed to template with all shapes according to needs.

Product advertage:

1.The transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2.It is good to keep surface warm so in winter the project can also be continued.

3.After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4. The film faced plywood can be used to make camber and it also can be cut into small pieces according the special requirements.

5.Environmentally friendly.

6.It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time