Loading Port:China main port

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:10 unit/month

Product introduction:

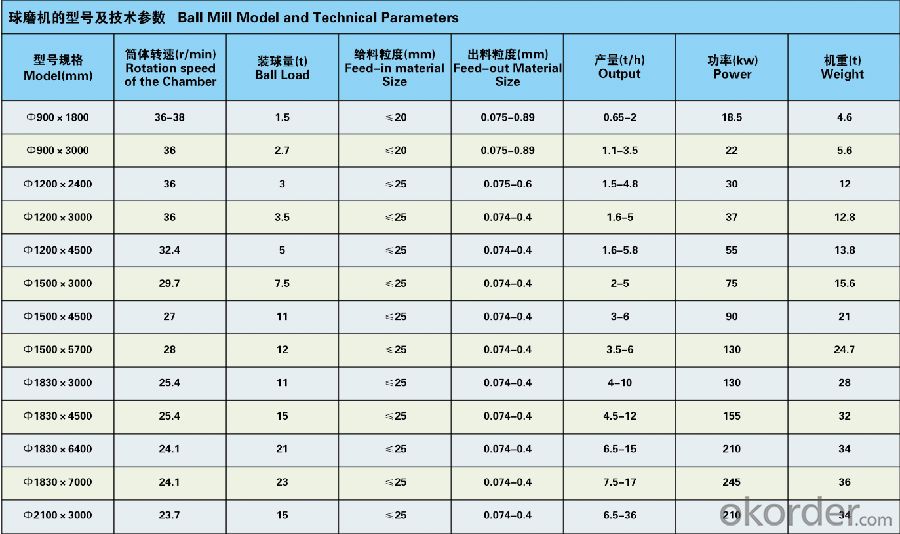

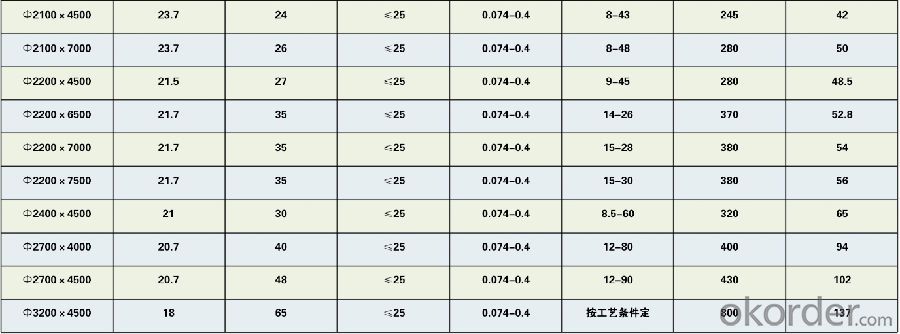

Ball mill is the key equipment for crushing materials after crushing, and it is one of the high-fine grinding machines widely used in industrial production. Ball mills are widely used in building materials, chemicals, cement, silicate products, new building materials, refractory materials, fertilizers, black non-ferrous metal dressings and glass ceramics industries to grind various medium hardness ores and other materials. According to the processing technology, it is divided into two types: dry and wet.

Performance characteristics:

The ball mill has less investment, energy saving compared with similar products, novel structure, easy operation, safe use, stable performance and reliable operation. It is suitable for mixing and grinding of ordinary and special materials. The hollow shaft is made of cast steel, the inner lining can be replaced, the rotary large gear is processed by casting hobbing, and the barrel is embedded with wear-resistant lining, which has good wear resistance. Users can choose the appropriate model and liner and media type according to the specific gravity and hardness of the material and according to the factors such as output.

Working principle:

the material is fed into the mill head by the feeding device through the hollow shaft of the feeding material. The chamber has a step liner or a corrugated liner. The steel ball of different specifications is built inside, and the cylinder rotates to generate centrifugal force. After falling to a certain height, it will hit and grind the material. After the material reaches the rough grinding in the head warehouse, it enters the second warehouse through the single-layer compartment board. The warehouse is equipped with a flat lining plate with steel balls inside to further grind the material. The powder is discharged through the discharge raft to complete the grinding operation.