Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:700 unit

Supply Capability:40000 unit/month

Bagless Cyclone Canister Vacuum Cleaner ErP standard CNCL6235

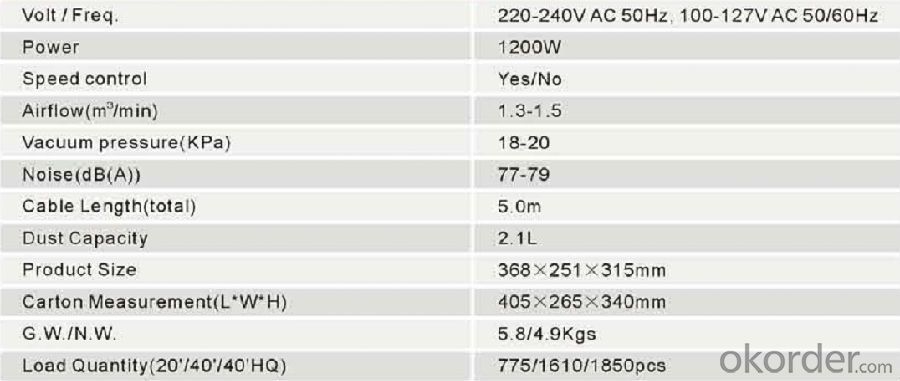

Model No. | CNCL6235 | ||

FEATURE: | Permanent bagless design with translucent dust compartment | ||

Specification: | |||

* Unit dimension | 368*251*315mm | ||

* Color | Injection and spray | ||

* Input voltage | 220~240V/50Hz | ||

* Nominal power | 700W | ||

* Dust tank capacity | 2.1L | ||

* Cable length | 5M | ||

* Speed control | Yes | ||

* Accessory | small nozzles, 1.5m hose | ||

1pc metal telescopic tube | |||

* Brush | High efficiency brush | ||

* Plug Type | optional | ||

* Motor power for ERP standard | 700W | 800W | 800W |

* Erp class | A | B | B(normal brush) |

* Motor power for Normal standard | 1200W-1400W | ||

Packing: | |||

* Gift box: | 405*265*340mm | ||

* Master carton: | N/A | ||

* Quantity/GB: | 1pcs/GB | ||

* Packaging material: | Double corrugated cardboard | ||

* loading qty (20'/40'/40H'): | 775/1610/1850pcs | ||

* N.W.: | 4.9KG | ||

* G.W.: | 5.8KG | ||

Trademark:OEM, ODM

Packing:Gift Box / Export Cartons

Standard:CE, GS, CB, EMC

Origin:China

FAQ

Q: What's the difference with cyclonic to multi-cyclonic filtration system?

Multi-cyclonic is where the dust container has a plastic filter section inside and has many little tunnels in it that separate the finer dust and dirt for the next filter and there is no HEPA filter in the middle plastic filter section.

Cyclonic filtration is where there is a central HEPA filter that sits inside the dust container and catches the finer dust.

Q: My vacuum just stopped while I was using it! What do I do now?

All of our vacuum cleaners have been fitted with a thermal safety cut-off switch which activates to stop the motor from burning out. When it does that it will prevent the unit from turning on again until it has cooled sufficiently to reset, which is between 2 – 4 hrs. The most common reason for safety cut-off switch activated is the filters needs to be cleaned. Please read the instruction manual and follow the instructions on how to clean the filters.